|

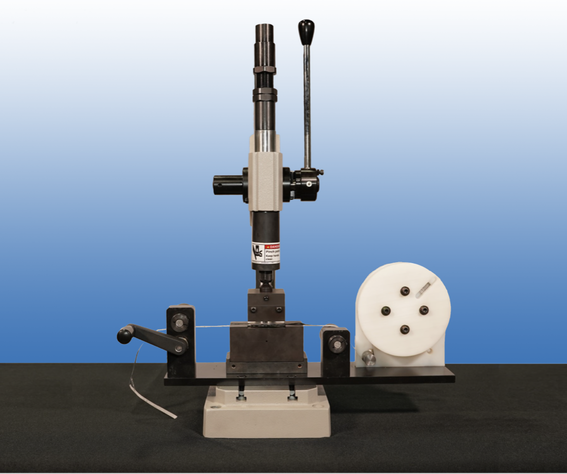

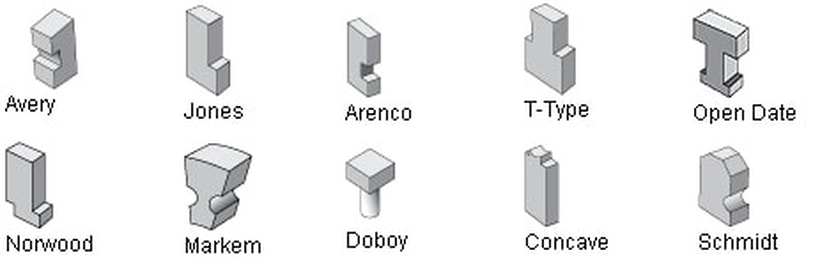

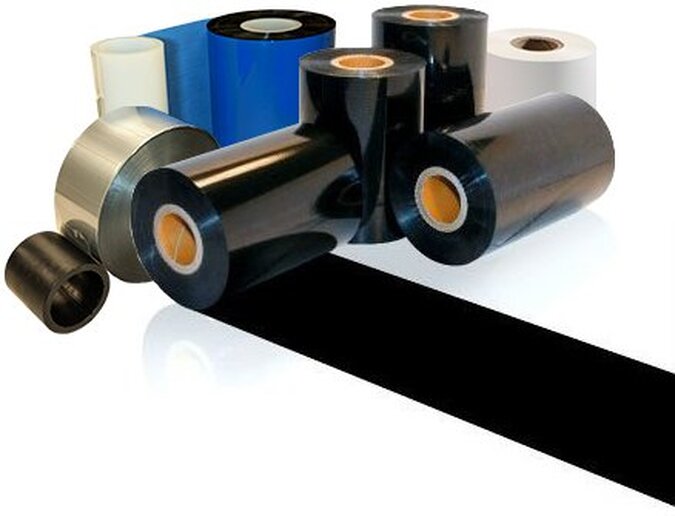

compiled & written by Bernard Martin Whether package marking lot numbers, expiration dates, case codes, 2D barcodes or general package date coding, Leading Marks has the replacement metal coding type and dies, type holders, hot stamping foil, hot melt ink rollers, rubber type, and thermal transfer ribbons needed to be your date coding supply specialist. Leading Marks can supply replacement products for nearly every OEM packaging machine including Markem-Imaje®, Norwood®, Kingsley®, Jones®, Norden®, Open Date®, Rommelag®, Videojet®, Diagraph®, Linx®, Domino®, and many more. Leading Marks can supply you brass and steel dies and Packaging Type used for coding, imprinting, labeling, embossing, and debossing. Our replacement packaging type and steel stamp dies are commonly used in cartoners, sealers, tube fillers, labelers, wrappers, thermoformers, pouchers and baggers (form/fill/seal), and imprinters for hot or cold marking of labels, tags, packages, cartons, boxes, plastic, and/or metal surfaces. Leading Marks carries a broad based package marking product lines to solve the widest variety of packaging marking applications and has the experience needed to make the very best recommendation for your situation. Take a look below at the wide variety of solutions! Metal Type and Logo Dies for Package Date CodingWe can supply brass and steel logo dies and packaging type used for coding, imprinting, labeling, embossing, and debossing. They are the largest manufacturer of replacement metal coding type for all of the popular OEM equipment including Norwood® Imprinters, Markem® Touch Dry Coders, Jones® Cartoners, Open Date® Labelers, Norden® Tube Fillers, Kalix® Tube Fillers, and many more. Thier replacement packaging type and steel stamp dies are commonly used in cartoners, sealers, tube fillers, labelers, wrappers, thermoform and imprinters for hot or cold marking of labels, tags, packages, cartons, tubes, boxes, and plastic. Foils and Ribbons for Date CodingLeading Marks supplies a variety of thermal transfer ribbons for imprinting variable data such as production dates, expiration dates, storage life, bar codes, and more on a wide range of substrates and across many industries including food and beverage, cosmetics, pharmaceuticals, manufacturing and more. Industrial Inkjet Printers for Package Date Coding & Part MarkingLeading Marks offers a variety of ThermalInkjet (TIJ) printers and configurations providing crisp high-resolution codes for both porous and non-porous products. Easy to use, hassle-free and afford able technology that can b e easily installed into both new and existing production lines. We supply inkjet printing systems to meet all of your direct part marking needs whether you need an inline inkjet printer or a portable inkjet printer. Hot Stamping Printers for Date CodingLeading Marks offers a complete line of hot foil stamping printers to meet all of your packaging requirements, including date coding, wire marking and heat shrink sleeving, and even decorative hot stamping for personalization.

0 Comments

written by Bernard Martin Did you know that the National Safety Council's NSC Safety Congress & Expo is happening from October 20-25? We thought this would be appropriate to talk about some safety issues for using markers in the workplace. Yes, you read that right. It's not generally a topic that is at the top of your mind so it's a great time to bring it to your attention so you and your team understand how all markers are not held to the same standards. Let's state some things that will make the lawyers happy first. Under normal general use, marking pens are 100% safe to use. Arro-Mark® manufactures and supplies markers to industrial clients. Most of our end-users are using the pens in the work place and are held to high standards in hazardous materials labeling, signage, and disclosure. Arro-Mark® ships its products according to the highest standards of disclosure of the hazardous materials. When compared to the competition, Arro-Mark® goes the extra mile to disclose on their packaging and labeling the information needed to keep their products usable in the workplace. Volatile Organic Compounds Volatile Organic Compounds (or VOC's) are materials that need to be listed cumulatively in the Safety Data Sheet (SDS) under section 9. When these materials break down, they pose health and environmental risks to air quality. Facilities that deal with large amounts of these chemicals dedicate a lot of resources to documenting and measuring VOC's in their environment. These places deal with enormous quantities of chemicals on a daily basis. Arro-Mark's facility and the marking pens they create pose minute, and in most cases, undetectable VOC concerns. Regardless of the danger or environmental impact these fumes impose, Arro-Mark lists VOC contents of thier products. Flammability Xylene is a bi-product of petroleum fuel production and is flammable. Alcohol has an even lower flash-point. In section 9 of Arro-Mark's Safety Data Sheets, they list the flash-points pertaining to each product mixture. When encased in their industrial quality marking pens, the markers are thoroughly protected from outside dangers. Only prolonged exposure to direct flame will have any hope of igniting an encased marking pen. Even though these great lengths are taken to protect the contents of thier pens, the flammability needs to be disclosed and is included in all of the SDS paperwork and on their labeling. Corrosiveness and Irritation Xylene, MIBK, Alcohols, and some pigments and dyes are listed in thier SDS and on labelling as potential irritants to skin and corrosive to the eyes. Some dyes and pigments used in Arro-Mark's paints and inks also show an Irritant pictogram on their Safety Data Sheets. Although you may see a corrosive pictogram on some of the labeling or Safety Data Sheets, Arro-Mark guarantees that their products are not corrosive to metals. Under general and proper use, a marking pen poses no danger in terms of corrosiveness to skin or eyes by way of splash-age or any other concern. Of course, Arro-Mark cannot guarantee the safety of products used improperly or outside the manufacturers recommended use. Concerns when transporting or keeping paint or inks in Drums, Bottle, or Cans Encased in a protective marking pen and confined to proper usage only, all of the above mentioned safety concerns are minimized. On the other hand, the same concerns mentioned before become exacerbated when keeping loose ink or paint in cans, bottles, and especially drums. This is because the risk of mishandling or spillage is higher. Arro-Mark always prefers to sell their products in the form of marking pens but occasionally have orders and a need to ship our paints and inks in loose containers. Arro-Mark goes to every length necessary and beyond to ensure the safe transport and full disclosure of all handling instructions and hazardous materials concerns pertaining to each shipment. Competitors are not held to same standards Uni-paint is a 100% xylene paint marker but they do not list the same concerns about Xylene that Arro-Mark does, and they are able to be marketed to a wider audience because of their less "alarming" labeling. Uni-paint also doesn't go to the hazardous materials documentation lengths that Arro-Mark does. Uni-paint are sold around the world and people assume that their marker is completely safe because of the absence of warnings. Arro-Mark's xylene paint markers pose the same risks but since Arro-Mark sells to industrial clientelle, their disclosure and display of hazard warnings are more prominent since their pens are made to be used on job site and the work-place. Sharpie for instance, and many others contain alcohols and other chemicals that you wouldn't want to be on the skin or exposed to flame. Yet these particular markers have made it into every office, stationary store, and school in the country. They have also been AP or Art Product Certified which excuses these products from needing any hazardous warnings on the product or safety data sheets. Pictograms and warning statements scare away customers Arro-Mark's pens are no more dangerous or hazardous than the competition's but they remain dedicated to disclosing hazardous concerns to their full extent. It may hurt their sales by being so thorough, but they believe that the most important concern is for our customers who use their products in the workplace. MSDS vs SDSMSDS is Material Safety Data Sheets, while SDS is just Safety Data Sheets. OSHA standardized the format, as well as simplifying the name, giving consistency with the Globally Harmonized System of Classification and Labeling of Chemicals (GHS). GHS specifies what information should be included on the Safety Data Sheets and it's the same standard used in the European Union. SDS is a simpler and more effective way to communicate the hazards of the chemicals used. Essentially, they just dropped the "M" You can learn more about SDS standards in this user-friendly 16 section format document. Don’t miss our 10th Anniversary MFG DAY SHOWCASE, Wednesday, October 11, at the Bayfront Convention Center in Erie, Pennsylvania! Join fellow area manufacturers, educators and more than 2,000 students to highlight the high-paying, high-tech careers that are available in today’s diverse manufacturing industry.

Make the MFG connection! This is the place where we showcase the products that Leading Marks represents to the manufacturing workforce of tomorrow! TWO BIG EVENTS . . . |

| The Tapmatic TapWriter allows you to mark your workpiece while you are machining it, without the need for a secondary marking operation. Part numbers, serial numbers, date codes, and even logos, can easily be created with this unique dot-marking tool. The TapWriter is easily installed on machining centers or CNC lathes with live tooling. It utilises standard engraving software, but unlike engraving, dot-peen marking does not require the use of delicate cutting tools and high-speed spindles. You can mark soft plastics or steel as hard as 55 RC. The durable carbide stylus is thrown against the work piece that allows the marking of uneven or round surfaces. The TapWriter is fast. Up to 80 characters per minute or more just depending on the capabilities of your machine. Dot peen marking is widely used in the aerospace industry because the cross section of the dot has gentle curves, resulting in no significant stress concentration. With the TapWriter you have complete control of the mark. The revolutions per minute determine the dots per minute, and the velocity of the carbide stylus when it impacts the work piece. |

Max BePOP Printers: Efficient Sign and Label Printing and Cutting Machines for Diverse Industries

7/11/2023

The Key Features

Max BePOP printers utilize advanced printing technologies to deliver sharp, vibrant, and professional-quality prints. Whether it's intricate designs, text, or images, these printers ensure accurate reproduction with stunning color accuracy.

Precise Cutting:

Alongside printing, Max BePOP machines excel at precise cutting. With their integrated cutting systems, these printers can effortlessly create custom-shaped labels, stickers, and signs, saving time and eliminating the need for manual cutting.

Versatility in Media Handling

Max BePOP printers are designed to handle a wide range of materials, including vinyl, adhesive films, paper, textiles, and more. This versatility allows for the creation of labels and signs for various applications, such as product labeling, retail displays, event signage, and industrial safety signs.

User-Friendly Software

The accompanying software for Max BePOP printers offers an intuitive interface that simplifies the printing and cutting process. It enables users to import designs, adjust settings, and precisely position and resize graphics, ensuring seamless production and minimal wastage.

Industries and Applications

The Max BePOP printers find extensive use in the retail industry for creating eye-catching product labels, shelf tags, and promotional signage. The ability to print and cut on-demand allows for quick updates and customization to match changing marketing strategies.

Packaging and Labeling

Max BePOP printers are well-suited for packaging and labeling applications. They enable the production of high-quality product labels, barcode stickers, and packaging inserts, ensuring brand consistency and compliance with industry standards.

Manufacturing and Industrial

In the manufacturing sector, Max BePOP printers streamline the production of industrial labels and safety signs. They can swiftly create warning labels, equipment tags, and instructional signs, enhancing workplace safety and efficiency.

Events and Exhibitions

Max BePOP printers are valuable assets for event organizers, enabling the creation of banners, posters, backdrops, and signage. With quick turnarounds and precise cutting capabilities, these printers cater to the dynamic and time-sensitive nature of event promotions.

Some Application Examples

Max BePOP printers allow beverage manufacturers to produce custom labels for their bottles, showcasing branding elements, nutritional information, and regulatory details accurately. The precise cutting feature ensures labels fit perfectly, enhancing the product's overall appeal.

Retail Store Signage

Retailers can utilize Max BePOP printers to design and print vibrant window displays, hanging signs, and floor decals. The ability to cut various shapes enables the creation of attention-grabbing visual merchandising elements, attracting customers and boosting sales.

Warehouse and Logistics

Max BePOP printers find utility in the logistics industry, where labels play a crucial role in inventory management and tracking. These printers can generate barcode labels, shipping tags, and custom packaging labels, improving operational efficiency and reducing errors.

From customized product labels to vibrant retail signage, Max BePOP printers provide exceptional performance, ensuring professional results and increased operational efficiency.

Give us a call if you would like a demo!

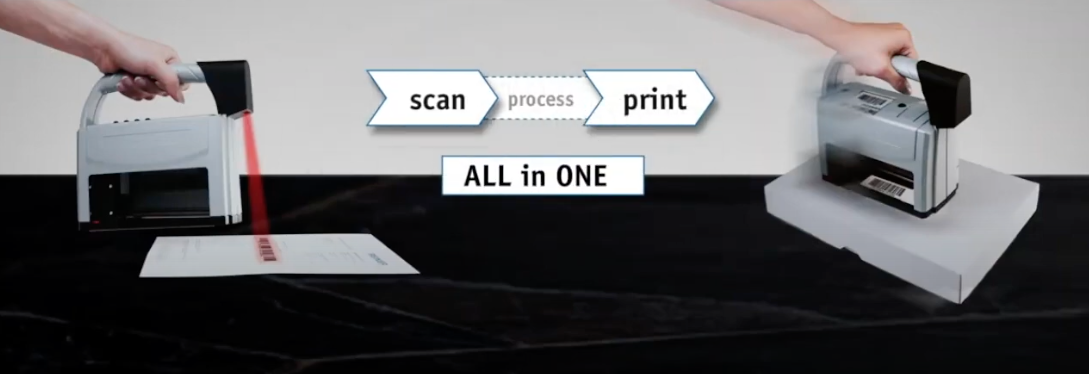

The 1025 with the barcode scanner is highlighted on this page and will scan, process and then print specified data all from the same unit! For more information on the other options see components below. Superior scanning and printing performance wrapped up in one!

All of the functionalities of the original 1025 carry through to this model. It is the most flexible and function packed handheld printer ever brought to market. With the click of a button, the 1025 can print up to a 1″ x 3 1/2″ imprint on both absorbent and non-absorbent surfaces. 1D & 2D barcodes, graphics, logos, & alphanumerics – all accomplished in about 1 second.

This unit is perfect for logistics, repackaging & relabeling, manufacturing, parts marking, inventory management, asset tracking, warehousing, factories, supply chain & a multitude of other vertical markets and applications. Compliance has never been easier with this zero-maintenance cartridge based system and Reiner’s industry unique self-traversing printhead. Printing on a variety of sizes and shapes is effortless, add in single and multi-line imprints, ERP/Database connectivity, and up to a 1″ print height and you’ve become unstoppable.

Performing Measurements & Printing at Once

Scales are indispensable helpers where weight is relevant. This is particularly the case in labs, pharmaceutical and cosmetic companies, or food manufacturers. Small and medium-sized operations often still use elaborate and error-prone interim steps for data processing before the determined weights can be recorded on the product.

This is where marking specialist REINER® from Furtwangen in the Black Forest comes in with its newly developed accessory items for the mobile jetStamp® 1025 sense inkjet printer. The V24/RS232 sensor is connected to the marking device and then to the available scales via the reliable RS232 port.

As soon as the scales have determined the weight, the jetStamp®1025 sense will display the measuring result. This can then be integrated into a pre-set print image, among other things, right away, which is then printed to the product – permanently and smear-resistant thanks to high-quality inks. Interim steps on other devices are not needed, which reduces errors in manual or automatic data transmission and saves working time.

TECHNICAL FEATURES

- Fully portable handheld inkjet printer – Thermal Inkjet (TIJ)

- Prints on absorbent and non-absorbent surfaces

- Prints single and multi-line imprints- depending on character size

- Print area up to 1″ height x 3 1/2″ length

- Adjustable font size- from 1/16″-1″

- Prints Graphics, 1D and 2D barcodes, and alphanumerics

- High Resolution 300DPI cartridge

- Connection to Windows-based programs, merchandise management systems or barcode label software

- Micro SD card data transfer and storage

- Stores up to 255 Imprints

- Lightweight: 2.1 lbs with batteries and cartridge

- ERP/database connectivity

- Bluetooth connectivity

- Network compatible

- Great for right and left-handed operators

- Ergonomic handling through multi-triggering: on the side and in the middle of the handle

- Black and Yellow Ink Options

- Unique Self-traversing printhead

- 4 Rechargeable AA Batteries

- This equipment is only compatible with PC computers. Not MAC compatible.

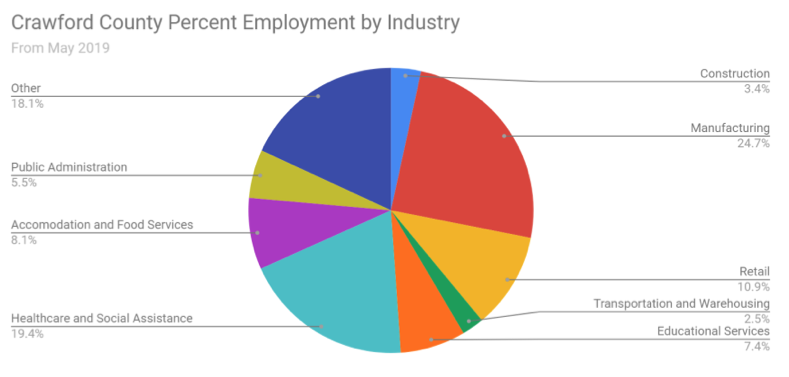

Meadville is located in Northwestern Pennsylvania and is the bedrock of the Crawford County economy, accounting for about a quarter of employment in the county. And those the jobs in the country are pretty much all in tool & die manufacturing!

Today, the Meadville area remains a leader in tooling, machining and advance manufacturing and the city serves as the region’s center for banking, education and social services.”

A recent study undertaken at Allegheny College entitled , Trends in the Tooling and Machining Industry of Crawford County, Pennsylvania states, "Starting in the early 20th century, the Talon Company started the production of area toolmakers. Through their apprenticeship programs, workers learned the art of toolmaking. Many workers at Talon spun off to create their own companies. Since then, the tooling and machining industry has helped sustain the county as a major source of employment, revenue generator, and an important factor in the vibrancy of the real estate and retail sectors."

Today Meadville is home to numerous small, medium and large tool and die shops, and is a leader in precision machining, plastic injection molding and aerospace engineering.

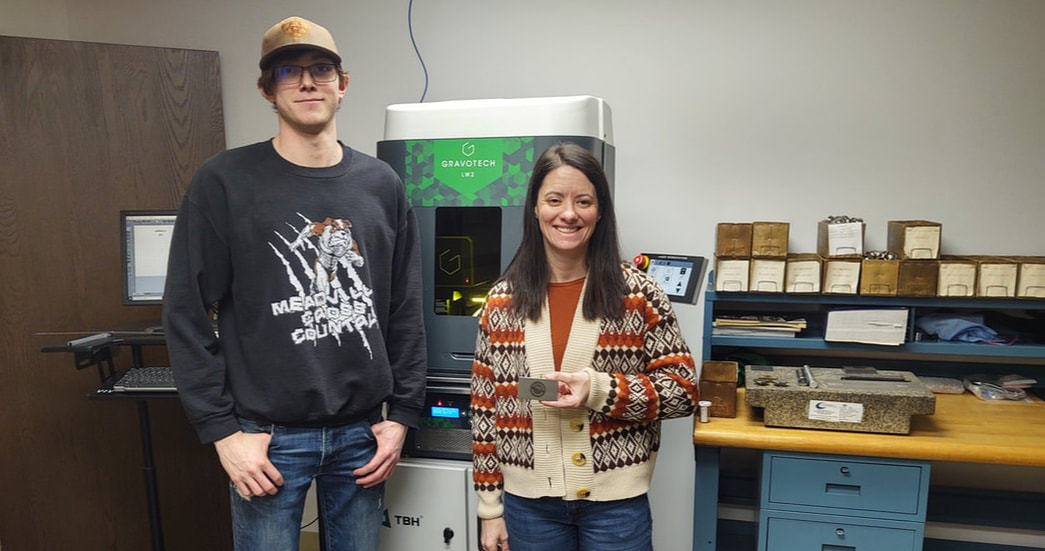

"The industry is now transitioning to a third generation set of owners, who bring new attributes to the industry... For the first time in the history of the industry, women are either the CEOs or operations managers of an increasing number of tool shops."

Area Tool & Manufacturing, Inc. certainly fits that description as a second generation woman owned family business, as it's now solely owned by Ashleigh Wehrle. Area Tool's TEAM consists of 13 employees with an average of 30 years of experience in the spare parts and mold industries and many of the shop floor employees are journeymen toolmakers. It's located just a few minutes from the Interstate 79 interchange in a 20,000 square foot climate-controlled building.

"Part buyers and engineers often assume they can save time and money on an assembly project by sourcing the components that make up their assembly from multiple shops. But the truth is that when more than one shop is responsible for precision machining as many as 100 components for a large assembly, issues with tolerance and fitment are common. The worst part? These problems remain hidden until the shipments arrive at your door. It’s only then that you discover that the components don’t fit together and the assembly doesn’t function properly."

|

That philosophy is put into practice according to Ashleigh Wehrle "We had historically used a local subcontract shop for our laser engraving needs. Our partner was very responsive to our needs and a pleasure to work with, but ultimately we were looking for an in-house solution."

Laurie Barcaskey, President of Leading Marks LLC, introduced herself and her company to Wehrle in the Spring of 2015. "We were evaluating equipment needs within our facility. We were mostly interested in laser marking solutions that Laurie could offer." Wehrle continues, "We were pleased with the solutions Laurie presented however chose to invest in larger equipment purchases that had taken priority." |

|

As a small shop, you have to pick and choose which area to invest your capital and then prioritize the order of that in investment. Sometimes it takes a few years.

Wehrle continues, "We revisited the need for in-house laser marking in the fall of 2021. We often times found parts would be ready to ship late in the day except for the laser engraving requirement."

That's a big problem for a machine shop that prides itself on meeting and exceeding delivery requirements.

"One of our customers had a part scheduled to ship overnight, but they needed it sooner, so they asked, “Could you get someone on a flight tonight?” That same evening, an Area Tool team member flew to Boston and hand-delivered the part to the customer. Requests like this one aren’t feasible for OEMs. But because of our size, we can tailor our services to customers’ unique needs." said Wehrle

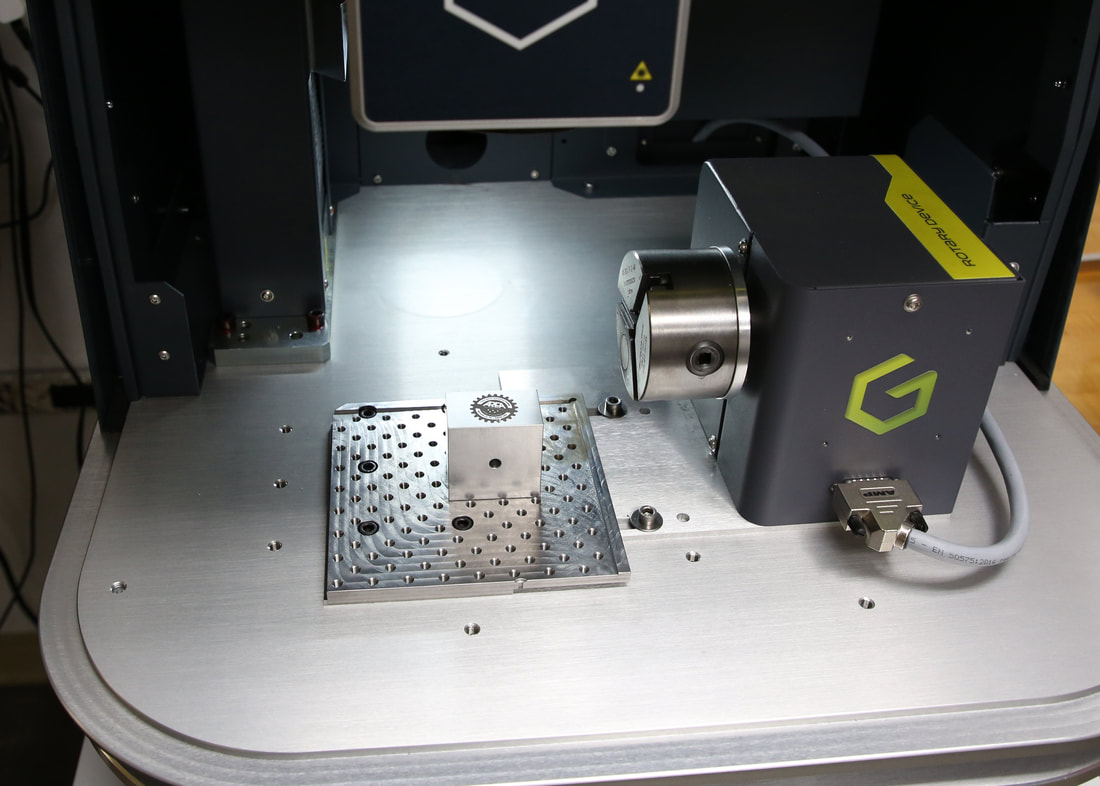

"The GravoTech solution with rotary head was a perfect fit for the low volume mill and lathe parts we manufacture. We are also able to label in house fixturing and tooling for better organization. We have also replaced our dot peen for marking to provide a customers with more professional marking." said Wehrle.

To sum it all up Wehrle says "Having the capabilities in house allows us to laser engrave and ship the parts 2-3 days sooner than if we continued to outsource." Automation continues to be embraced at every size machine shop as qualified labor continues to become more difficult to find.

Identifying and developing a career plan is a challenge for students. BotsIQ holds a pivotal position as a workforce development program that attracts smart, capable students who love to build things and solve problems — exactly the type of people that will comprise the future manufacturing workforce.

Through BotsIQ,

- Students work together in a fascinating real-world professional manufacturing model.

- Students gain in-demand technical skills like mechanical engineering and design, electrical engineering, machining, 3D printing, and more.

- Each participating school is paired with a local manufacturing company to serve as their industry mentor and learn about the potential for a career in manufacturing

You can also meet with Laurie Barcaskey, President of Leading Marks. Laurie is volunteering at this event that runs from April 28-29, 2023, 7:30AM – 6:00PM

| There will surely be tons of sparks and lots of excitement! Complete our registration form to let us know you will be joining us! | LOCATION PennWest California Convocation Center 250 University Avenue, California, PA 15419 |

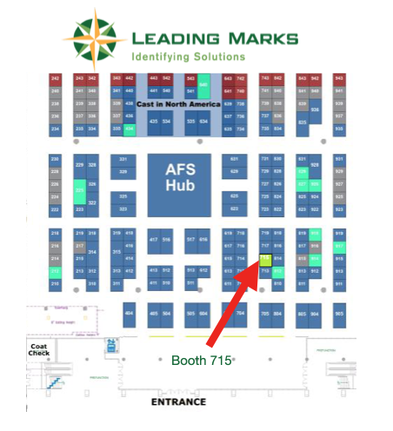

Nestled along Lake Erie’s southern shore, Cleveland is the second largest city in Ohio. Huntington Convention Center of Cleveland is hosting Metalcasting Congress 2023, providing over 410,000 square feet of prime meeting and event space. The convention center is also just 25 minutes away from Cleveland Hopkins International Airport.

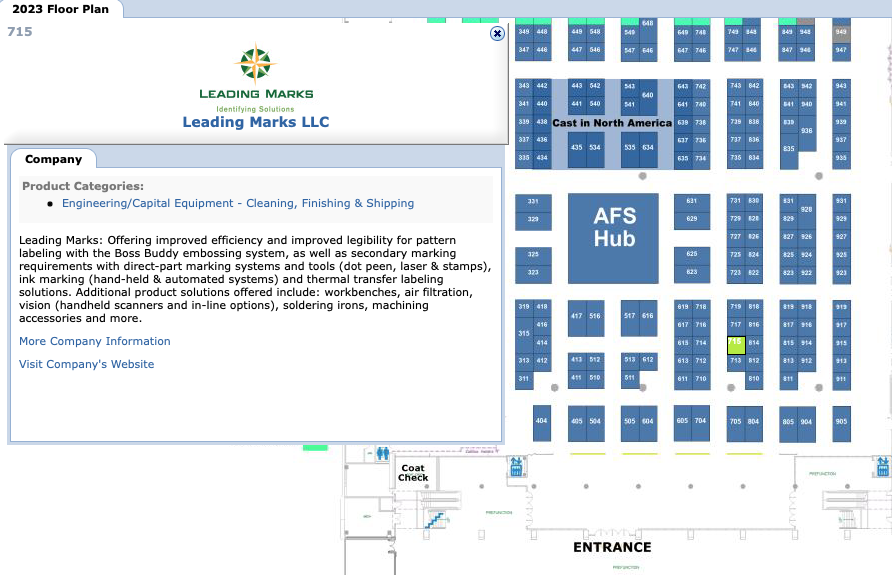

Leading Marks & Boss Buddy

Booth 715

| We will also be showcasing secondary marking requirements with direct-part marking systems and tools such as dot peen, laser & stamps, ink marking, hand-held & automated systems, and thermal transfer labeling solutions. We will also be discussing workbenches, air filtration, vision handheld scanners and in-line options, soldering irons, and machining accessories. Huntington Convention Center Cleveland, OH April 25 – 27, 2023 Leading Marks Booth 715 |

Explore the Future of Metalcasting at Leading Marks Booth 715!

Leading Marks will be previewing improved efficiency and improved legibility for pattern labeling with the Boss Buddy embossing system, as well as secondary marking requirements with direct-part marking systems, dot peen, laser & stamps, ink marking, hand-held & automated systems and thermal transfer labeling solutions. Additional product solutions offered include: workbenches, air filtration, vision, handheld scanners and in-line options, soldering irons, machining accessories and more.

Leading Marks will be demonstrating the following products in our booth #715

Boss Buddy

The Boss Buddy makes it simple to produce pattern labels. With consistently embossed characters the end-results provide better legibility of heat numbers, date codes and other traceable cast in identification of cast products.

EBS 260 Handjet Portable Printer

The EBS Handjet product line is designed to deliver the highest performance. They are ideal for printing on porous and non-porous materials. Some of those substrates include foil, glass, metal, lumber, concrete, and various other surfaces.

Durable Mecco Stamp Grip

Durable Technologies' Safety First Stamp Grip provides improved hand protection and better marks. It provides a safer alternative for operators who prefer to hold stamps in-hand. Pocket sizes range from 1/4" to 1" square. Your hand stamp must be a minimum of 2.5" in length to work in the Safety First Stamp Grip.

Visit Leading Marks at Booth 715

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it.

Archives

May 2024

April 2024

March 2024

February 2024

January 2024

December 2023

November 2023

October 2023

September 2023

August 2023

July 2023

June 2023

May 2023

April 2023

March 2023

February 2023

January 2023

November 2022

October 2022

September 2022

August 2022

July 2022

May 2022

March 2022

December 2021

November 2021

September 2021

August 2021

July 2021

May 2021

March 2021

February 2021

January 2021

December 2020

July 2020

June 2020

May 2020

April 2020

March 2020

February 2020

January 2020

December 2019

November 2019

October 2019

September 2019

August 2019

July 2019

June 2019

April 2019

March 2019

January 2019

December 2018

November 2018

October 2018

September 2018

August 2018

July 2018

June 2018

May 2018

April 2018

March 2018

February 2018

January 2018

December 2017

October 2017

September 2017

July 2017

June 2017

May 2017

April 2017

December 2016

September 2016

August 2016

July 2016

June 2016

May 2016

April 2016

February 2016

January 2016

August 2015

October 2014

July 2010

Categories

All

AFS Medtalcasting Congress

AFS Pittsburgh

Area Tool

Arromark

Automator

Benson Foundry

Bepop

BizMix

Boss Buddy

Bots IQ

Case Study

Cembre

Clamping

Covid

Date Codes

Design 2 Part

Direct Part Marking (DPM)

Dot Peen

Durable Mecco

EBS Ink Jet

Embossing Dies

Flexpak

Foundry Society

Foundry Solutions

Fundamentals

Gravotech

Handjet

Handstamp

Hexacon

HFO Demo Day

Honeywell

Hot Stamping

IMTS

ITT Gould Pumps

JetStamp

Labeling

Laser Marking

Laurie Barcaskey

Leading Marks

LEDLenser

Manufacturing Expo

Marking

Marking Indsutry Magazine

Max USA

Mfg Advanced Expo

MFG Day

Mitee Bite

Modern Casting

Modern Machine Shop

Nameplates

NTMA

OSHA Compliance

Pitt Chem Day

Presentations

Promotions

Reiner

Reiner Jetstamp 1025

Rising Rust Belt

Roll Dies

Scanners

SDS & MSDS

Signage

Stamping Press

Steel Stamps

Supply Chain

Tags

Tapmatic

Tapmatic MH Marking Head

TBH

TBH BF -Series

TBH GL-Series

Tech Article

Technifor

Technomark

Testimonials

Thermal Printing

Traceability

Trade Shows

Unique Device Identification (UDI)

Videos

WBENC - Women’s Business Enterprise National Council

WBE Women’s Business Enterprise

WBE - Women’s Business Enterprise

Workholding

WOSB - Women Owned Small Business

Zuess Marking

RSS Feed

RSS Feed