Understanding Marking

Whether you are seeking to identify a component or part, put a warning label or sign in place to alert for potential risk, or mark the location for which an item will be stored or located in inventory, marking has never been so needed. This page will help you understand the basic fundamentals of part marking

Industry is demanding identification to assist in minimizing risk; multi-vendor supply of components begs that all parts are marked as origin of supply or be held responsible for the other guys mistakes. Liability concerns expect manufacturers to add precautionary labeling that warns of potential risks to the operator or for maintenance requirements.

Identification consists of applying an asset number, part number, serial number, QA/QC inspection approval or rejection, Corporate logos and/or industry symbols, heat codes, date codes, or a multitude of other types of detail. The process of defining the type of mark requires evaluation of options to determine the best method. Leading Marks, LLC, offers a wide range of marking methods that provide solutions based on the situation.

Some of the key factors to consider when you are evaluating your marking process include and are not limited to:

Industry is demanding identification to assist in minimizing risk; multi-vendor supply of components begs that all parts are marked as origin of supply or be held responsible for the other guys mistakes. Liability concerns expect manufacturers to add precautionary labeling that warns of potential risks to the operator or for maintenance requirements.

Identification consists of applying an asset number, part number, serial number, QA/QC inspection approval or rejection, Corporate logos and/or industry symbols, heat codes, date codes, or a multitude of other types of detail. The process of defining the type of mark requires evaluation of options to determine the best method. Leading Marks, LLC, offers a wide range of marking methods that provide solutions based on the situation.

Some of the key factors to consider when you are evaluating your marking process include and are not limited to:

|

Factoring in industry requirements may require the use of bar codes or other traceable identification that will survive cradle-to-grave in varying environments. Temporary marking needs verses permanent identification requirements impact the method used, including the budget needed for the solution.

Leading Marks, LLC, offers a wide range of marking methods to meet the demands of your process. We can provide you with solutions for the following marking methods

To learn more about the common marking applications, methods, and industries served, explore the information and links below:

Leading Marks, LLC, offers a wide range of marking methods to meet the demands of your process. We can provide you with solutions for the following marking methods

To learn more about the common marking applications, methods, and industries served, explore the information and links below:

Fundamentals of Marking Blog Series

Fundamentals: Challenges of Marking Different Materials - There are some rather unique challenges associated with marking different materials. Here's a short overview of things to think about. This article reviews the basics of marking Metal, Wood, Plastics and other materials. This is really the best place to start to learn about marking.

Fundamentals of of Direct Part Marking - Direct Part Marking (DPM) is used most frequently when marks are needed on a variety of materials like metals, plastics and wood. Common equipment solutions range from traditional hand stamping processes to cutting edge technology of fiber laser marking. Direct part marking is often a less costly alternative to purchasing RFID tags.

Fundamentals of Dot Peen - This versatile marking technology creates the marking details one dot at a time. Marks can be alpha/numeric, symbols, logos and 2-D bar codes. System configurations can be stand-alone bench models, hand-held and integrated into production lines. Dot peen systems are able to mark components and materials up to 59RC hardness.

Fundamentals of Hot Stamping - Contrast marking on plastics, wood, leather and other substrates can easily be done with presses equipped with tape that suits the material, or with branding irons. Interchangeable type can be used in holders or custom marking dies made with logos and patterns. Applying identification on to substrates such as plastic, leather and wood for decorative purposes or where other marking methods are not most feasible. Marking methods represented include: Branding Irons, Presses and Marking Dies & Foils.

Fundamentals of Ink Marking - Enhance the traditional rubber stamp and stencil marking processes. Devices are available to suit a variety of colors and chemistries that allow marking on metals, plastics, cloth, wood, cardboard, and more. Print alpha/numeric characters, symbols, including serialization and date codes, as well as bar codes quickly without the mess. Computerized and wireless hand-held, and in-line ink marking systems are available, as well as traditional rubber stamps, daters and stencils & rollers.

Fundamentals of Impact Marking - Spring-loaded impact presses, roll markers and other mechanical machines allow for marking details that can be permanently stenciled or indented onto the components. Serial numbers, date codes, part identification and other marking details can be quickly applied for traceability.

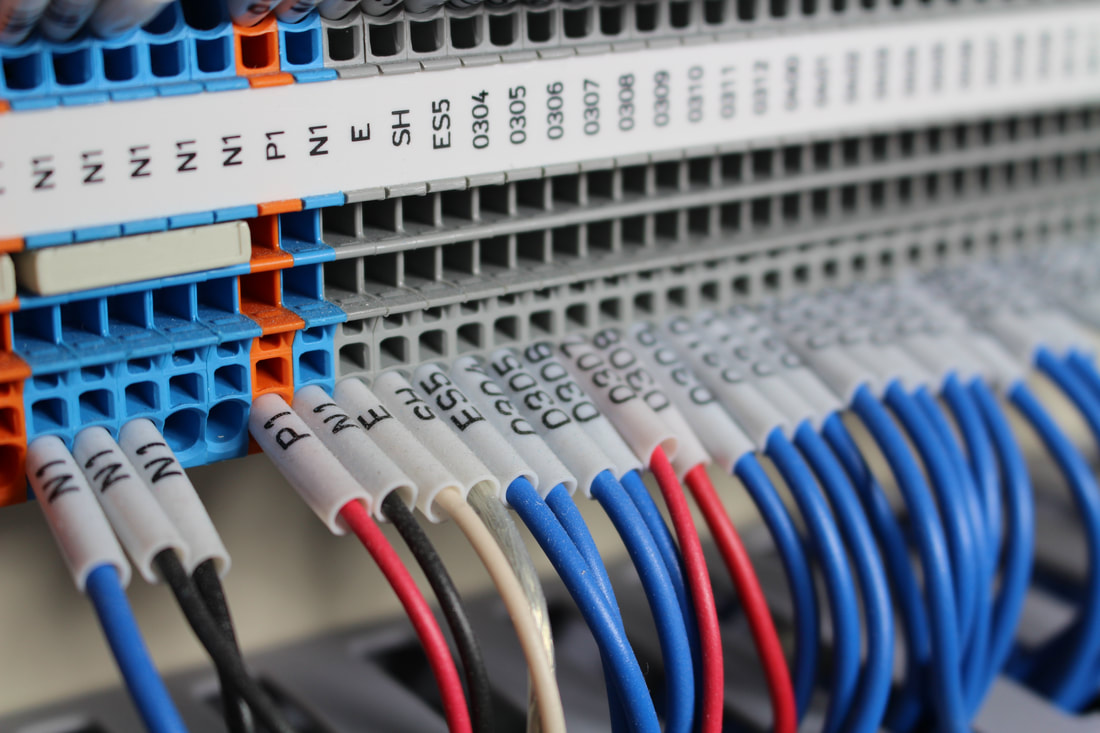

Fundamentals of Labeling - Print on-demand for high volume labeling requirements, or job specific with thermal transfer printers up to 300 x 600 dpi. Terminal blocks, wire id and other electronic components can be marked quickly and clearly.Pre-printed labeling options are great for repetitive application of warning labels, container identification, and other decorative application requirements.

Fundamentals of Laser Marking - Permanent identification without product deformation can be accomplished with laser marking by light surface etch, oblation or deep engraving. Depending on the substrate being marked, the available cycle time, and the power of the laser permanent direct-part marks can be applied quickly from stand-alone work stations to fully integrated marking systems.

Fundamentals of RFID - Radio-Frequency identification is becoming a popular labeling method that allows for real time machine interface & reporting, quickly locating a component or asset, capture equipment details, and much more. Options for RFID labeling can be simple labels with adhesive, or rugged devices that survive in almost any environment.

Fundamentals of Signage Machines - Whether it is directing safe egress in an emergency or alerts for moving vehicles on the shop floor signs bring awareness to the circumstances of where you are and where you are going. As automation increases to optimize production signs offer warnings about hazards. On construction sites signs encourage use of safety gear requirements. The demands of indoor versus outdoor signage differs, as does the need for which it will serve. A wayfinding sign on a manufacturing floor or power sub-station may not demand the aesthetics of one in a commercial office building.

Fundamentals of Steel Stamps, Type & Dies - Steel stamps, often times referred to as stencils or punches, provide options for application of individual characters, inspection symbols, or other variable data. Steel type allows multiple characters to be ganged in type holders for quick application of consistent marking details. Available for straight or curved line arrangements for flat or round component marking requirements.

Fundamentals of Tags and Nameplates - Industrial tagging is needed for temporary identification or for secure identification in harsh-environments. Nameplates offer equipment details including manufacturer details that aid in service requirements and asset identification. Applied to products or assets for quick reference and note industry compliance. These items are available in plastic, metals, paper and cloth with various retaining options such as adhesive, holes for riveting or screwing, wire strings, or other tamper-resistant mechanisms. Nameplate options include but are not limited to: Blank Plates, fully Engraved Sets, Asset & Security, Bar code and RFID.

For more information about identifying solutions for marking contact Leading Marks today