|

Technomark Easy connect hand held dot peen is a portable, wireless, energy self-sufficient, network-connected dot peen machine. compiled & written by Bernard Martin "We found out about Leading Marks through the web. We contacted Laurie and she did a great presentation and was able to teach the system during the sales call. One of the things we liked best about working with Laurie is her expertise, She knows her products and their capabilities thoroughly." says Ed DeMailo, General Manager, at MetalWerks Inc.  Metalwerks dot peen sample Metalwerks dot peen sample Metalwerks, Inc. has over twenty years of experience melting and processing vacuum melted specialty metals. They operate five vacuum melting furnaces and bar processing equipment at their facilities in Aliquippa, PA. Metalwerks serve customers in the medical, industrial, and aerospace industries as well as research and development projects. Typically alloy systems at Metalwerks include Fe, Ni, Co, Cu, Ti, and Zr in quantities ranging from 300 grams up to 6000 pounds. Through their network of outside processors they convert ingot into bar, plate, coil and/or sheet. "The Easy, the Dot Peen marking system offers an unrivaled level of functionality. Being easy to use while delivering an exceptional operating experience to the user. Easy is ideal for mobile use, since the unique and durable, yet the lightweight chassis allows a user to mark medium to large parts in even the most difficult and inaccessible locations." said Laurie Barcskey, owner of Leading Marks, LLC. "The dot peen marking system has served us quite well: No more smashed fingers, Clarity of the letters, and no problem training operators." says DeMailo. I would recommend Leading Marks to other companies because they really understand and know their equipment. They are great to work with !!!!" If you have any questions about portable dot peen marking solutions, get in contact with Laurie!

0 Comments

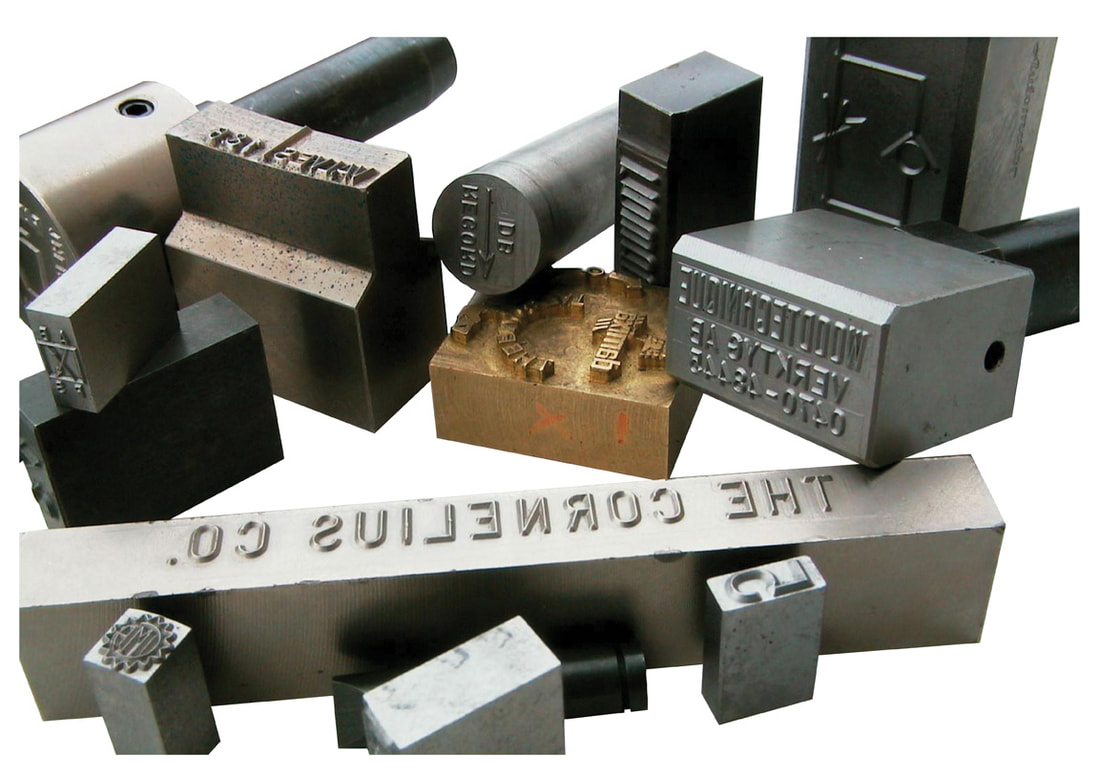

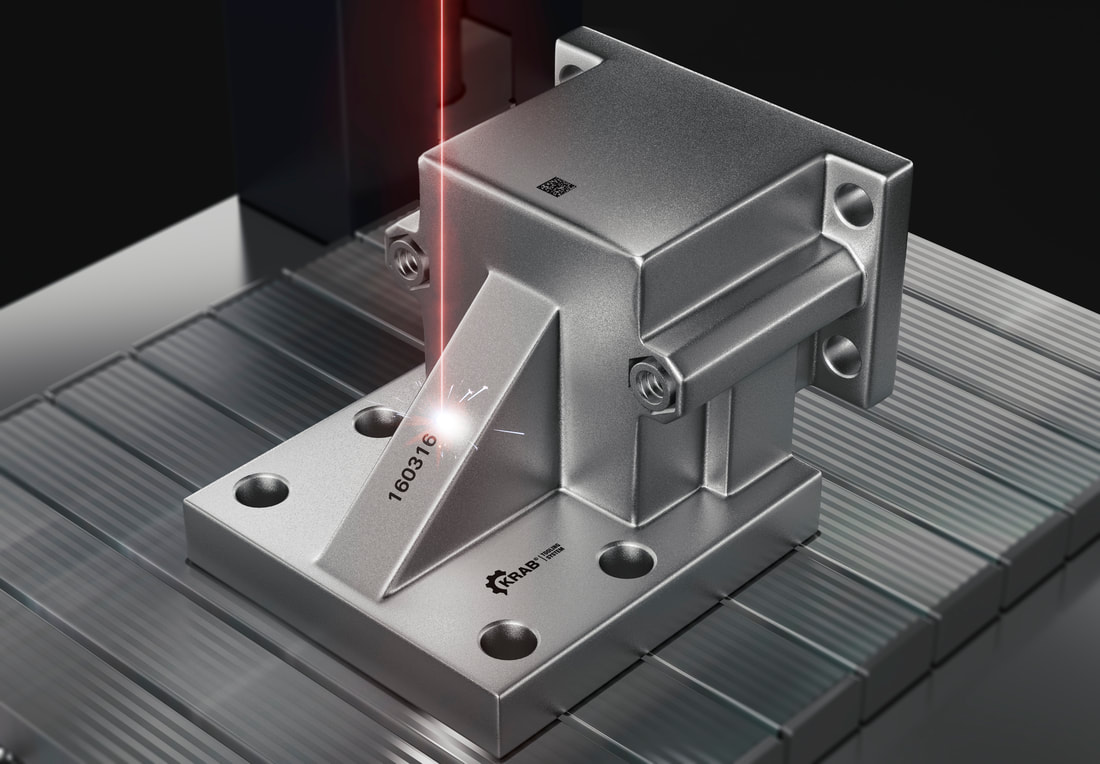

written by Bernard Martin Did you know that the National Safety Council's NSC Safety Congress & Expo is happening from October 20-25? We thought this would be appropriate to talk about some safety issues for using markers in the workplace. Yes, you read that right. It's not generally a topic that is at the top of your mind so it's a great time to bring it to your attention so you and your team understand how all markers are not held to the same standards. Let's state some things that will make the lawyers happy first. Under normal general use, marking pens are 100% safe to use. Arro-Mark® manufactures and supplies markers to industrial clients. Most of our end-users are using the pens in the work place and are held to high standards in hazardous materials labeling, signage, and disclosure. Arro-Mark® ships its products according to the highest standards of disclosure of the hazardous materials. When compared to the competition, Arro-Mark® goes the extra mile to disclose on their packaging and labeling the information needed to keep their products usable in the workplace. Volatile Organic Compounds Volatile Organic Compounds (or VOC's) are materials that need to be listed cumulatively in the Safety Data Sheet (SDS) under section 9. When these materials break down, they pose health and environmental risks to air quality. Facilities that deal with large amounts of these chemicals dedicate a lot of resources to documenting and measuring VOC's in their environment. These places deal with enormous quantities of chemicals on a daily basis. Arro-Mark's facility and the marking pens they create pose minute, and in most cases, undetectable VOC concerns. Regardless of the danger or environmental impact these fumes impose, Arro-Mark lists VOC contents of thier products. Flammability Xylene is a bi-product of petroleum fuel production and is flammable. Alcohol has an even lower flash-point. In section 9 of Arro-Mark's Safety Data Sheets, they list the flash-points pertaining to each product mixture. When encased in their industrial quality marking pens, the markers are thoroughly protected from outside dangers. Only prolonged exposure to direct flame will have any hope of igniting an encased marking pen. Even though these great lengths are taken to protect the contents of thier pens, the flammability needs to be disclosed and is included in all of the SDS paperwork and on their labeling. Corrosiveness and Irritation Xylene, MIBK, Alcohols, and some pigments and dyes are listed in thier SDS and on labelling as potential irritants to skin and corrosive to the eyes. Some dyes and pigments used in Arro-Mark's paints and inks also show an Irritant pictogram on their Safety Data Sheets. Although you may see a corrosive pictogram on some of the labeling or Safety Data Sheets, Arro-Mark guarantees that their products are not corrosive to metals. Under general and proper use, a marking pen poses no danger in terms of corrosiveness to skin or eyes by way of splash-age or any other concern. Of course, Arro-Mark cannot guarantee the safety of products used improperly or outside the manufacturers recommended use. Concerns when transporting or keeping paint or inks in Drums, Bottle, or Cans Encased in a protective marking pen and confined to proper usage only, all of the above mentioned safety concerns are minimized. On the other hand, the same concerns mentioned before become exacerbated when keeping loose ink or paint in cans, bottles, and especially drums. This is because the risk of mishandling or spillage is higher. Arro-Mark always prefers to sell their products in the form of marking pens but occasionally have orders and a need to ship our paints and inks in loose containers. Arro-Mark goes to every length necessary and beyond to ensure the safe transport and full disclosure of all handling instructions and hazardous materials concerns pertaining to each shipment. Competitors are not held to same standards Uni-paint is a 100% xylene paint marker but they do not list the same concerns about Xylene that Arro-Mark does, and they are able to be marketed to a wider audience because of their less "alarming" labeling. Uni-paint also doesn't go to the hazardous materials documentation lengths that Arro-Mark does. Uni-paint are sold around the world and people assume that their marker is completely safe because of the absence of warnings. Arro-Mark's xylene paint markers pose the same risks but since Arro-Mark sells to industrial clientelle, their disclosure and display of hazard warnings are more prominent since their pens are made to be used on job site and the work-place. Sharpie for instance, and many others contain alcohols and other chemicals that you wouldn't want to be on the skin or exposed to flame. Yet these particular markers have made it into every office, stationary store, and school in the country. They have also been AP or Art Product Certified which excuses these products from needing any hazardous warnings on the product or safety data sheets. Pictograms and warning statements scare away customers Arro-Mark's pens are no more dangerous or hazardous than the competition's but they remain dedicated to disclosing hazardous concerns to their full extent. It may hurt their sales by being so thorough, but they believe that the most important concern is for our customers who use their products in the workplace. MSDS vs SDSMSDS is Material Safety Data Sheets, while SDS is just Safety Data Sheets. OSHA standardized the format, as well as simplifying the name, giving consistency with the Globally Harmonized System of Classification and Labeling of Chemicals (GHS). GHS specifies what information should be included on the Safety Data Sheets and it's the same standard used in the European Union. SDS is a simpler and more effective way to communicate the hazards of the chemicals used. Essentially, they just dropped the "M" You can learn more about SDS standards in this user-friendly 16 section format document. In essence, Direct Part Marking (DPM) is applying identification that lasts from cradle to grave and will sustain very rugged environments. Many US government agencies are making unique device identification (UDI) and direct part marking (DPM), mandatory. The private sector, from automotive manufacturers to medical offices have been using DPM more and more as they have embraced the Deming Principles of TQM. Direct Part Marking is used most frequently when marks are needed on a variety metals, plastics and wood. Common equipment solutions range from traditional hand stamping processes to cutting edge technology of fiber laser marking. Direct part marking is often a less costly alternative to purchasing RFID tags. When to Choose Direct Part Marking

Direct Part Marking Options

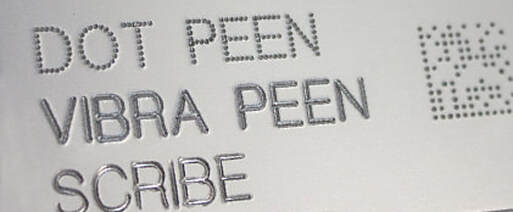

2D Codes: Most Popular for Direct Part Marking In most cases, direct part marking applications use two-dimensional (2D) barcodes such as Datamatrix or QR Code, which carry much more data than linear (1D) barcodes. By using 2D barcodes, manufacturers can also identify very small items and parts.  Dot Peen vs Vibra Peen vs Scribe and a 2D QR code Dot Peen vs Vibra Peen vs Scribe and a 2D QR code 2D codes can pack a large amount of data as opposed to linear codes because they can carry data in two directions on the code vs. just one. To give you an idea of the relative size, a 1D barcode can store around 25 characters up to about 80 characters depending on whether it’s Code 128 or Code 39, but a 2D code can store up to 2,000 characters. In the automotive sector, there is an established standard (AIAG B11) for direct part marking, and a number of large auto OEMs like Ford require suppliers of certain components to use DPM for part traceability. Manufacturers like to use the 2D code not only for the storage capacity, but for their relative size as well (square vs. rectangular). The flexibility of a 2D code allows for the variation in the amount of information stored in the barcode as well as the size of the item being marked. The most popular uses of the mark are for applications that require:

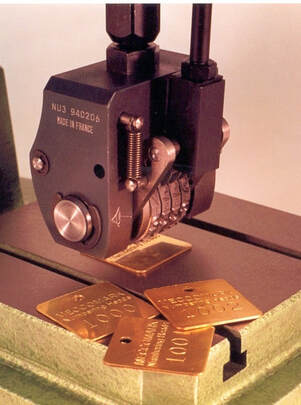

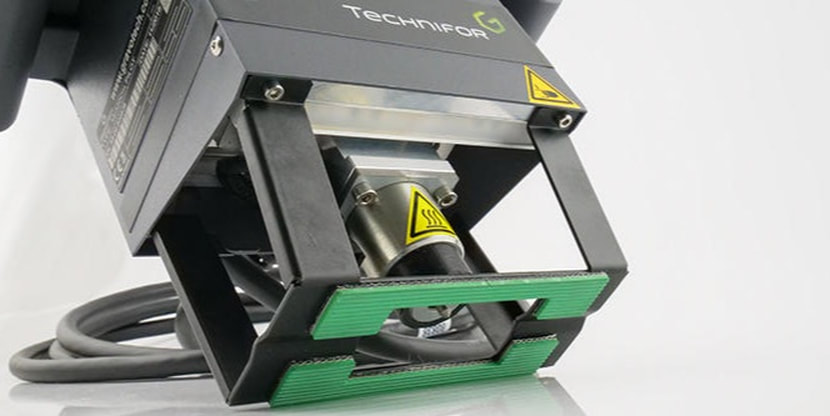

Kurt J. Lesker Company® (KJLC®) is the leading global provider of high-quality vacuum equipment, that services the LEDs, Optics, UHV/Synchrotrons, Electronics, Wear and Decorative Coatings and R&D markets. Leading Marks tested and installed a Gravotech XM500 ENv2 LM portable dot peen part marking system. The Gravotech - Technifor XM500 is a lightweight and robust portable marking machine with an ultra-compact design that allows you to mark where you want, when you want. It can be used for marking small and large parts as well as parts with complex shapes and difficult to access areas. Combined with the new XCOM Control Unit, the XM500 is the most comfortable and intuitive marking machine on the market! According to Roxanne Shurtz, CNC Supervisor at Kurt J. Lesker Company, "Leading Marks was able to answer any questions that I had. The technical support was knowledgeable and efficient. I appreciated Leading Mark’s quick response time, knowledge of products, and product availability." Our new Gravotech, handheld dot peen tool gives us the ability to quickly change our marking needs from job to job. The production staff finds it easy to understand and use. I would recommend Leading Marks because of their outstanding customer service and knowledge. They offer innovative products and ideas." TRC Services Inc. offers a full suite of Sucker Rod Products and Services is designed to help your rod pumping operation work more efficiently in the most cost-effective manner. "We found Leading Marks through a web search as we looked to improve our current dot peen equipment as we implemented the marking of the API monogram to our products." said Stephen Ewing, Quality Manager at Total Rod Concepts (aka TRC Services Inc).

"We would absolutely recommend Laurie Barcaskey of Leading Marks to other companies that have marking and traceability challenges because the customer service before and after the sale and the ongoing technical support is fantastic. The products are top of the line and performance has changed our processing for the better."

|

Follow us on LInkedIN for the latest breaking news!

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it. Archives

May 2024

Categories

All

|

RSS Feed

RSS Feed