|

Technomark Easy connect hand held dot peen is a portable, wireless, energy self-sufficient, network-connected dot peen machine. compiled & written by Bernard Martin "We found out about Leading Marks through the web. We contacted Laurie and she did a great presentation and was able to teach the system during the sales call. One of the things we liked best about working with Laurie is her expertise, She knows her products and their capabilities thoroughly." says Ed DeMailo, General Manager, at MetalWerks Inc.  Metalwerks dot peen sample Metalwerks dot peen sample Metalwerks, Inc. has over twenty years of experience melting and processing vacuum melted specialty metals. They operate five vacuum melting furnaces and bar processing equipment at their facilities in Aliquippa, PA. Metalwerks serve customers in the medical, industrial, and aerospace industries as well as research and development projects. Typically alloy systems at Metalwerks include Fe, Ni, Co, Cu, Ti, and Zr in quantities ranging from 300 grams up to 6000 pounds. Through their network of outside processors they convert ingot into bar, plate, coil and/or sheet. "The Easy, the Dot Peen marking system offers an unrivaled level of functionality. Being easy to use while delivering an exceptional operating experience to the user. Easy is ideal for mobile use, since the unique and durable, yet the lightweight chassis allows a user to mark medium to large parts in even the most difficult and inaccessible locations." said Laurie Barcskey, owner of Leading Marks, LLC. "The dot peen marking system has served us quite well: No more smashed fingers, Clarity of the letters, and no problem training operators." says DeMailo. I would recommend Leading Marks to other companies because they really understand and know their equipment. They are great to work with !!!!" If you have any questions about portable dot peen marking solutions, get in contact with Laurie!

0 Comments

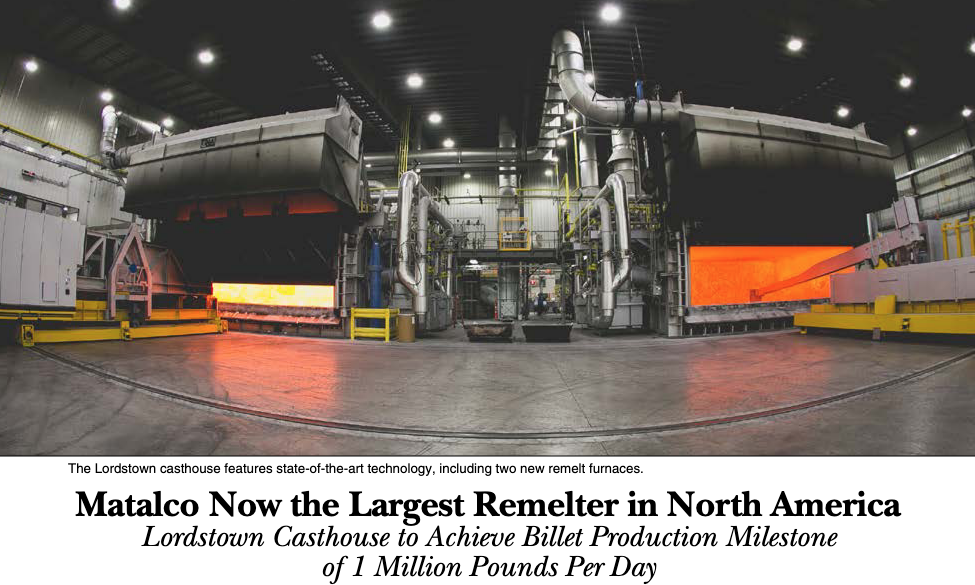

Kurt J. Lesker Company® (KJLC®) is the leading global provider of high-quality vacuum equipment, that services the LEDs, Optics, UHV/Synchrotrons, Electronics, Wear and Decorative Coatings and R&D markets. Leading Marks tested and installed a Gravotech XM500 ENv2 LM portable dot peen part marking system. The Gravotech - Technifor XM500 is a lightweight and robust portable marking machine with an ultra-compact design that allows you to mark where you want, when you want. It can be used for marking small and large parts as well as parts with complex shapes and difficult to access areas. Combined with the new XCOM Control Unit, the XM500 is the most comfortable and intuitive marking machine on the market! According to Roxanne Shurtz, CNC Supervisor at Kurt J. Lesker Company, "Leading Marks was able to answer any questions that I had. The technical support was knowledgeable and efficient. I appreciated Leading Mark’s quick response time, knowledge of products, and product availability." Our new Gravotech, handheld dot peen tool gives us the ability to quickly change our marking needs from job to job. The production staff finds it easy to understand and use. I would recommend Leading Marks because of their outstanding customer service and knowledge. They offer innovative products and ideas." Matalco Inc.’s three operations are strategically located in Brampton, ON, Canton, OH, and their state-of-the-art $100 million facility in Lordstown, OH positioned them as the largest remelter in North America. At their Canton, Ohio, facility, Matalco makes new products and aluminum billets from recycled materials. They are using the Bepop printer to make safety-related labels and PPE diagrams. In addition, Matalco is making labels for things around the plant to improve visual literacy such as daily production information, safety metrics, and labels for hard hats to show certification information. They plan on expanding their use of the tool to label storage locations to make sure things are put away and improve efficiency. Before they purchased the MaxUSA Bepop printer, Matalco would have to call a graphics designer, create a PO, have it printed elsewhere, and pick the labels up. According to Emily Seibert, the Environmental Health and Safety Specialist at the Canton facility, “Today if we have an idea, boom, we can do it today. We don’t have to wait a week…we can do it right here.” Emily stated that the system was pretty easy to use and user-friendly from the start, particularly f you are familiar with Microsoft tools like Powerpoint and Paint. The information for this testimonial from Leading Mark’s customer came from the video shown below. Watch it to learn more about Matalco’s experience with the MaxUSA Bepop CPM-100HG5 label printer. According to James Horomanski at Majr Products "We learned about Leading Marks via google when we searched for “new marking equipment.” Laurie not only responded to our email but she came out to see our processes and learn more specifics about our marking and production needs. MAJR Products Corporation, a Veteran Owned Small Business, based in Saegertown, PA is a leading manufacturer of EMI shielding and radio frequency shielding products. MAJR’s products include a variety of shielding gaskets, shielded ventilation panels, and EMI shielded windows. Mr. Horomanski continues "Initially we were interested in a dot peen system; but we began looking at other options when testing revealed that the indentations damaged our product’s EMI protection. Laurie suggested that we consider the Reiner JetStamp and it has been a lifesaver." Prior to using the Jetstamp MAJR Products had to roll the mark onto the part using a 2-part epoxy ink with rubber rib type, and then affix a label. It was a messy process that resulted in poor quality marks – especially once the type was worn. "Now Majr just use the JetStamp, a hand-held, ink marking system, to label parts with the required information. The time needed for this element of our production has been cut in half, if not more." says Horomanski.

TRC Services Inc. offers a full suite of Sucker Rod Products and Services is designed to help your rod pumping operation work more efficiently in the most cost-effective manner. "We found Leading Marks through a web search as we looked to improve our current dot peen equipment as we implemented the marking of the API monogram to our products." said Stephen Ewing, Quality Manager at Total Rod Concepts (aka TRC Services Inc).

"We would absolutely recommend Laurie Barcaskey of Leading Marks to other companies that have marking and traceability challenges because the customer service before and after the sale and the ongoing technical support is fantastic. The products are top of the line and performance has changed our processing for the better."

Thomas Erie, Inc. is a Girard, PA based company that produces quality metal stamped parts. They serve markets such as electronics, automotive and aerospace Their capabilities include stampings from 0.25 to 0.55 mm, Gasketing, embossing & anodizing. Thomas Erie, Inc. is part of the Thomas Group, the world’s largest independent supplier of tinplate and aluminum components for the aerosol, pharmaceutical and cosmetic industry. The Thomas Group employ 500 people worldwide. They produce stamped and deep drawn parts on progressive tools and transfer presses in Germany, the USA, Spain, China and Argentina. "We have been working with Laurie Barcaskey since 2014." said Foster Nickel the Toolroom Manger.

Foster explained, " We originally purchased an Automator Laser Engraver for marking our parts only for identification purposes. One day shortly after purchasing the engraver we found ourselves with a rush order for some debossed parts and the vendor we typically purchase our graphite anodes from could not meet our customer’s timeline. " "We don't have a high speed mill able to make the fine detail on the anodes required to meet our customer specifications and typically outsource this item. We were able to utilize the laser engraver to cut the graphite anode and then using our EDM sinker make our own debossing tool with laser point accuracy." said Foster, "This cut our lead time down from weeks to minutes and eliminated the cost of outsourcing completely." Foster found Leading Marks' Laurie Barcaskey very helpful. "Laurie offers good pricing, provides good service and is able to answer our questions. We would recommend her for your next project!" Get in touch with Laurie with any questions! JADCO Manufacturing, Inc. in Harmony , PA, is a leading global provider of wear resistant steel products to combat impact and abrasion challenges for over 40 years. Founded in August of 1980, JADCO offers an unparalleled array of proprietary products to optimize operations.

Neff Automation in Warrendale, PA specializes in providing automation products and solutions to enhance manufacturing and assembly processes and improve productivity in a wide variety of industries. We focus our activities toward manufacturing process improvement, productivity enhancement, total cost management and downtime reduction. Neff offers Automation Products, Sub-Assembly, Custom Designed Solutions and Inventory Optimization. "Neff Automation, previously Intek Systems, once shared office space with Laurie Barcaskey. Since she started Leading Marks, Neff have partnered with her for our marking requirements. She also makes referrals to us when automation is required." said, Rob Kozminski, Panel Shop Foreman at Neff.

"Leading Marks was able to help change our process for making panel plates. Previously we were going outside to engrave 2-ply materials, which caused lost production time for travel. With the new thermal printing process we are now able to print in-house and make adjustments to layouts as needed, and this printing process has also expanded our printing capabilities. It also allows us to use the printed label as a template for drilling holes for switches at the same time." continued Rob. "We would definitely recommend Leading Marks. Laurie is easy and pleasant to work with, and responds to emails and questions quickly. We appreciate her broad knowledge on marking technologies and that if she doesn’t know the answers she will put us in contact with someone who does." |

Follow us on LInkedIN for the latest breaking news!

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it. Archives

May 2024

Categories

All

|

RSS Feed

RSS Feed