|

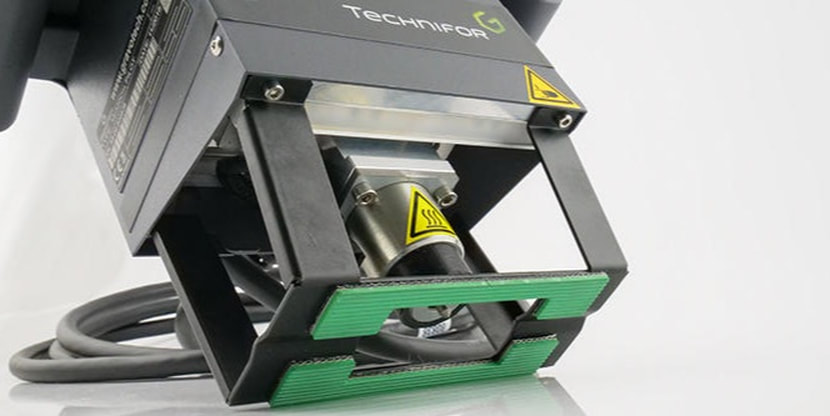

Machines that Make the Signs for the Times Whether it is the elegant requirements of architectural signs, meeting ADA (Americans with Disabilities ACT) wayfinding requirements, or durable safety signs that survive rugged environments how you make the sign matters. Leading Marks is an authorized distributor of the GravoTech engraving systems and the MAX USA Bepop 4-color thermal printers. Specializing in identification requirements, Leading Marks believes in presenting options that allow the customer options to meet the expectations of the job and work within the available budget for the capital investment. Engraving MachinesGravoTech, a leader of direct part marking machinery, offers a complete line of rotary and laser engraving machines. The rotary systems come in compact units for simple tasks of creating small legend plates, switch plates and more.

Thermal PrintersSafety signage and labeling is a critical part of the safety process for manufacturing and construction alike — especially for specialty contractors such as electrical and mechanical. ANSI and OSHA requirements give guidelines to help identify areas where danger or caution should be exercised during operation and/or maintenance of equipment.

The 4-color MAX USA Bepop printers are available in two sizes: 4” and 8”. An investment in either machine allows you to make signs on-demand. They even allow you to cut to size. Signs to GoIf you are not sure investing in capital equipment for your label and sign needs makes sense, Leading Marks also provides stocked and made-to-order solutions too. When these needs arise, it is always helpful to understand your needs. It is also helpful to know the environment for which the label and sign will be used, and the driving need for it. With this information we can recommend the applicable material the sign should be made of meeting ANSI and OSHA requirements. Artwork in digital format expedites the ability to respond quickly. Common standard and customized signs are available for biohazard and hazardous materials, safety, first aid, lockout tagout, machine operation and personal protection. Even rugged applications for aerial, pipelines, substations, traffic signals and other rugged industrial or construction site requirements.

0 Comments

It's really a case study of how small family owned machine shops prioritize for growth.

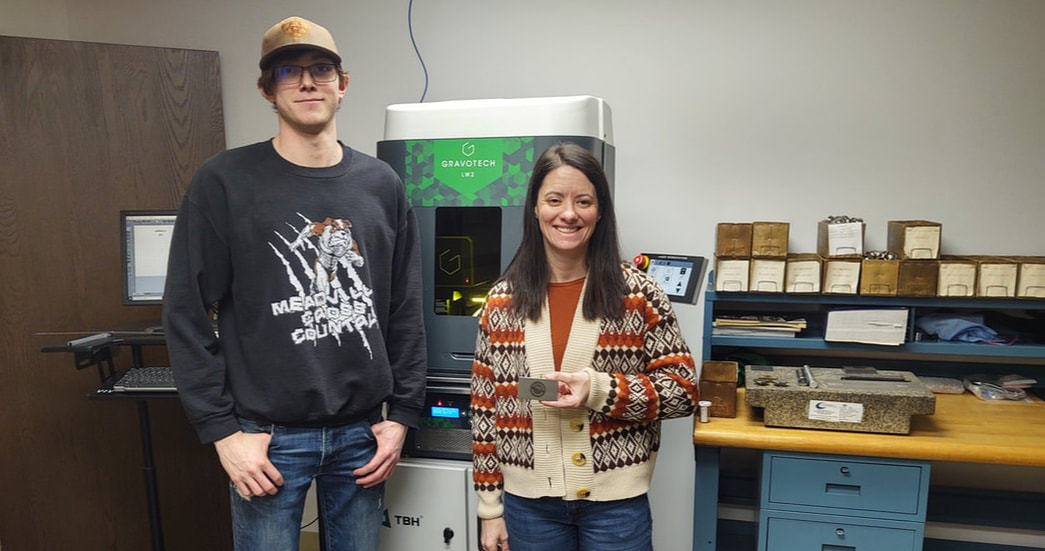

Area Tool & Manufacturing's Team: Trisha Proper - Office Manager, Dave Groshner - Surface Grind Department, Ethan Bates - CNC Mill Department, Dalton Conley - CNC Mill Department, Rob Hillman - CNC Mill Department, Jason Bowman - CNC Lathe Department, Matt Linz - Apprentice, Caroll Conley - WIRE EDM and Inspection, Jeff Ferguson - RAM EDM Department, Pat Winters - Maintenance Jesse Conley - Production, Ashleigh Wehrle - President

Area Tool & Manufacturing, Inc. was founded in Meadville, PA in 1976 by John Wehrle and business partner Wayne Shumaker. In 1990 John became the sole owner of the family business. Like many Tool & Die makers in Meadville, John got his start at Talon, Inc. Talon invented the zipper at the turn of the 20th Century and their renowned journeyman program has resulted in Meadville becoming known as the Tool and Die Capital of the World.

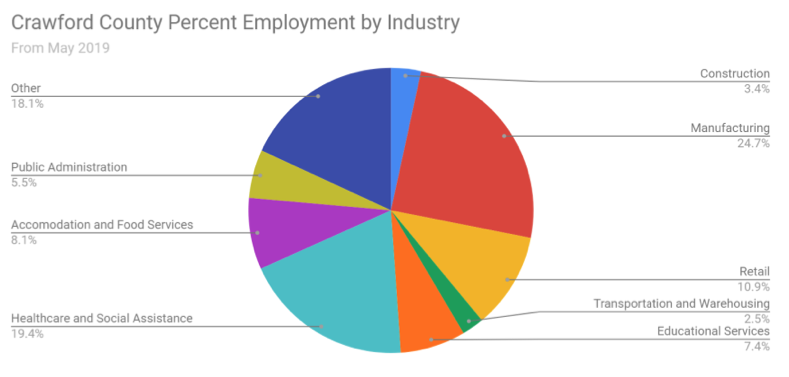

Meadville is located in Northwestern Pennsylvania and is the bedrock of the Crawford County economy, accounting for about a quarter of employment in the county. And those the jobs in the country are pretty much all in tool & die manufacturing!

According to the City of Meadville, “the Talon Corporation played a major role in the market development and manufacture of the zipper… In the 1980’s, the Great Lakes region saw a major decline in heavy industry. This blow to the local economy was softened by a subsequent surge in light industry, mainly tool and die machine shops, earning Meadville the nickname Tool City, USA.

Today, the Meadville area remains a leader in tooling, machining and advance manufacturing and the city serves as the region’s center for banking, education and social services.” A recent study undertaken at Allegheny College entitled , Trends in the Tooling and Machining Industry of Crawford County, Pennsylvania states, "Starting in the early 20th century, the Talon Company started the production of area toolmakers. Through their apprenticeship programs, workers learned the art of toolmaking. Many workers at Talon spun off to create their own companies. Since then, the tooling and machining industry has helped sustain the county as a major source of employment, revenue generator, and an important factor in the vibrancy of the real estate and retail sectors." Today Meadville is home to numerous small, medium and large tool and die shops, and is a leader in precision machining, plastic injection molding and aerospace engineering. "The industry is now transitioning to a third generation set of owners, who bring new attributes to the industry... For the first time in the history of the industry, women are either the CEOs or operations managers of an increasing number of tool shops." Area Tool & Manufacturing, Inc. certainly fits that description as a second generation woman owned family business, as it's now solely owned by Ashleigh Wehrle. Area Tool's TEAM consists of 13 employees with an average of 30 years of experience in the spare parts and mold industries and many of the shop floor employees are journeymen toolmakers. It's located just a few minutes from the Interstate 79 interchange in a 20,000 square foot climate-controlled building.

Area Tool exemplifies how the next generation of leadership is embracing technology and prioritizing how they grow their business. A recent blog post on their website titled, 4 Reasons to Source All Assembly Components from the Same Precision Machine Shop:

"Part buyers and engineers often assume they can save time and money on an assembly project by sourcing the components that make up their assembly from multiple shops. But the truth is that when more than one shop is responsible for precision machining as many as 100 components for a large assembly, issues with tolerance and fitment are common. The worst part? These problems remain hidden until the shipments arrive at your door. It’s only then that you discover that the components don’t fit together and the assembly doesn’t function properly."

That's also a trend in the Meadville market for small and mid sized shops according the the Allegheny College study, "Employment in our sample shops decreased by 18% between 2008 and 2018, a trend that reflects declines in manufacturing employment both in the United States and globally. This decrease in employment in Crawford County is not due to falling demand for toolmakers. Rather, many shops are still having difficulty finding skilled toolmakers. Technological change and automation in the industry have resulted in less need for skilled toolmakers. Most of the shops interviewed have invested heavily in new equipment, about $320,000 per shop within the past two years."

As a small shop, you have to pick and choose which area to invest your capital and then prioritize the order of that in investment. Sometimes it takes a few years. Wehrle continues, "We revisited the need for in-house laser marking in the fall of 2021. We often times found parts would be ready to ship late in the day except for the laser engraving requirement." That's a big problem for a machine shop that prides itself on meeting and exceeding delivery requirements. "One of our customers had a part scheduled to ship overnight, but they needed it sooner, so they asked, “Could you get someone on a flight tonight?” That same evening, an Area Tool team member flew to Boston and hand-delivered the part to the customer. Requests like this one aren’t feasible for OEMs. But because of our size, we can tailor our services to customers’ unique needs." said Wehrle

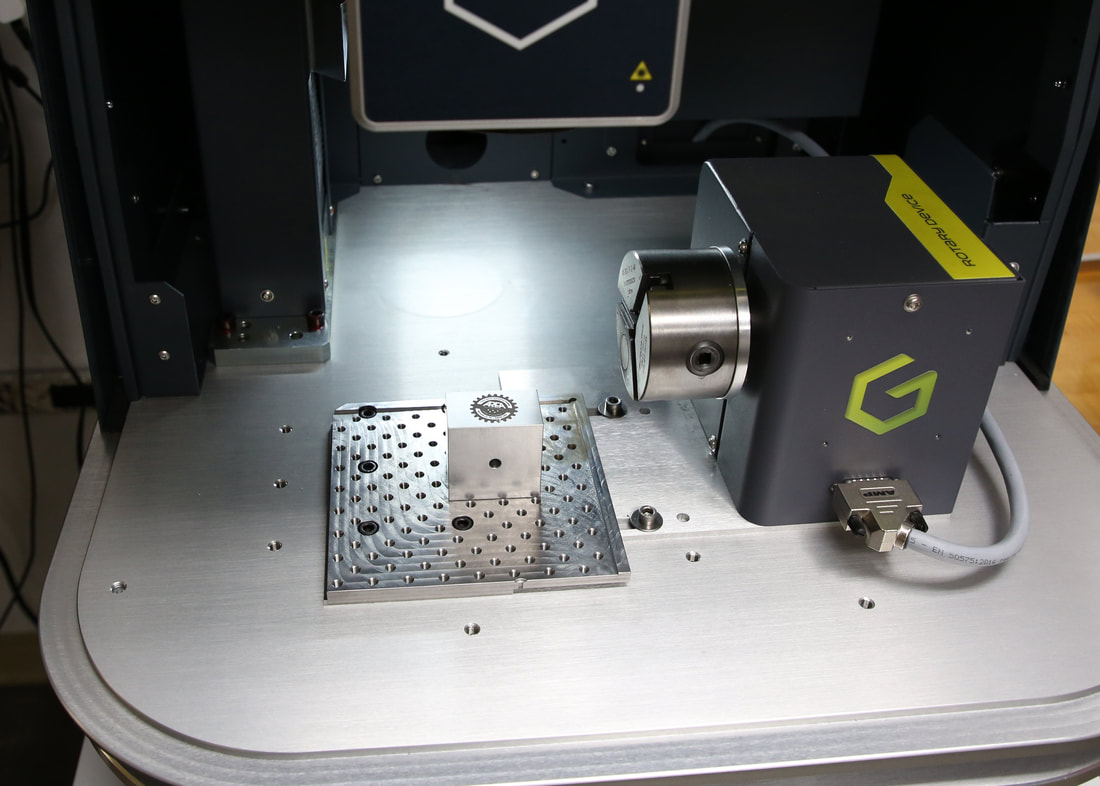

In January of 2022 Barcaskey installed a GravoTech LW2 which is a fully automated laser marking station.

"The GravoTech solution with rotary head was a perfect fit for the low volume mill and lathe parts we manufacture. We are also able to label in house fixturing and tooling for better organization. We have also replaced our dot peen for marking to provide a customers with more professional marking." said Wehrle. To sum it all up Wehrle says "Having the capabilities in house allows us to laser engrave and ship the parts 2-3 days sooner than if we continued to outsource." Automation continues to be embraced at every size machine shop as qualified labor continues to become more difficult to find. This article is originally from Technomark entitled: "What Is Dot Peen Marking? Ask anyone inside the industrial manufacturing industry – part-marking is crucial to component traceability when working with large quantities.

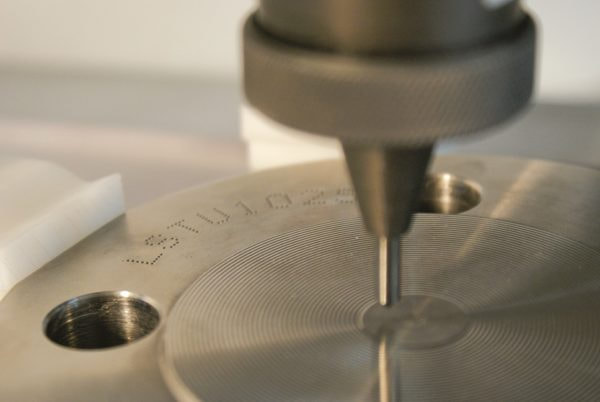

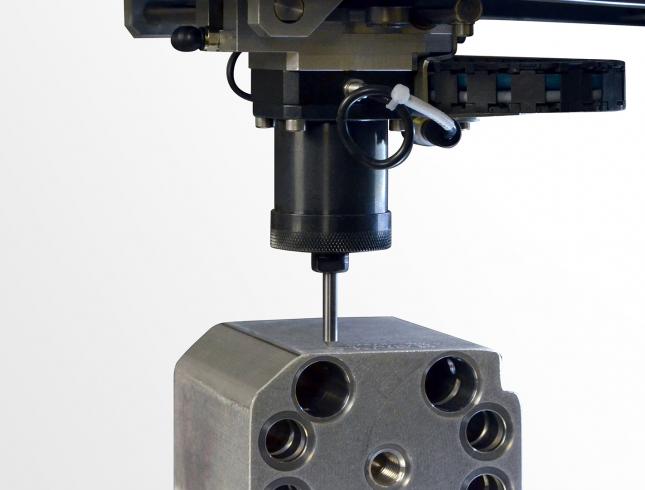

The Basics of Dot Peen MarkingIf you took apart a Dot Peen machine, one of the most important components you would find is a carbide or diamond-tip stylus. The Dot peen process is considered a “low-stress” marking method because the mark is generated via material displacement rather than material removal. The carbide stylus strikes the material surface to produce the mark via a series of cold-formed stamped dots. Compared to Laser Marking Systems, Dot Peen does not induce thermal shock to the part surface since the material is cold-stamped rather than super-heated to produce the mark. Dot Peen systems are commonly used by manufacturers in the aerospace and oil & gas industries where low-stress marking is required, such as tubular and flow control products that are exposed to extreme pressure differential in the oilfield. Dot Peen marking is viable for material hardness up to 63 HRC. Typically, when a part hardness is greater than 63 HRC, laser marking systems are recommended. All of Technomark’s Dot Peen machines rely on an electromagnetic solenoid to actuate the marking stylus. Dots are plotted in an X/Y plane via electronic control for precise placement of the Dot pattern. Using electromagnetic force versus pneumatic also provides a greater level of control of both the depth of the mark as well as the ability to mark contoured or complex surface. Dot Peen Marking: Component Traceability In ActionDot Peen marking machines are utilized in almost every industrial-goods manufacturing operation, including:

While these machines can run in-line and handle large quantities in an automated production environment, most are operated manually using a battery pack to go mobile.

Whether the part has a curved, wavy, or complex geometry, the stylus will follow the contour of the marking surface while maintaining a constant depth of marking throughout. When structural integrity is crucial, Dot Peen marking provides a low-stress marking solution that removes no material when marking the part. Why Choose Dot Peen MarkingOne of the biggest benefits of a Dot Peen Marking Machine is its ability to efficiently produce marks compared to other marking systems. Other benefits of Dot Peen machines include:

New and exciting dot peen innovations have just been introduced! Be on the lookout for machines that feature:

Leading Marks can help you with traceability from the shop floor where machine to machine communication and data-collection is crucial to mobilizing reporting from the warehouse or in the field.

Traceability is common for collection, look-up and sharing of data. Whether it is Asset Tracking, EH&S Inspections, QA/QC Controls, Work-in-process, Assembly builds, or Field Service reporting industry is driving the need for traceability from cradle to grave. Why is traceability important for your organization? What’s the value-add with the potential of data collected through mobile apps or plant-floor software packages?

Kurt J. Lesker Company® (KJLC®) is the leading global provider of high-quality vacuum equipment, that services the LEDs, Optics, UHV/Synchrotrons, Electronics, Wear and Decorative Coatings and R&D markets. Leading Marks tested and installed a Gravotech XM500 ENv2 LM portable dot peen part marking system. The Gravotech - Technifor XM500 is a lightweight and robust portable marking machine with an ultra-compact design that allows you to mark where you want, when you want. It can be used for marking small and large parts as well as parts with complex shapes and difficult to access areas. Combined with the new XCOM Control Unit, the XM500 is the most comfortable and intuitive marking machine on the market! According to Roxanne Shurtz, CNC Supervisor at Kurt J. Lesker Company, "Leading Marks was able to answer any questions that I had. The technical support was knowledgeable and efficient. I appreciated Leading Mark’s quick response time, knowledge of products, and product availability." Our new Gravotech, handheld dot peen tool gives us the ability to quickly change our marking needs from job to job. The production staff finds it easy to understand and use. I would recommend Leading Marks because of their outstanding customer service and knowledge. They offer innovative products and ideas."

The Boss Buddy Accessory Package

Direct Part Marking

Ink Marking Solutions

Thermal Transfer Labeling

Related Manufacturing Equipment

Looking Ahead to 2021 Looking Ahead to 2021 we are excited about the solutions our vendor partners are providing to manufacturing operations, construction projects and food processing requirements. Whether your needs are for marking or the related equipment Leading Marks is prepared to help evaluate your applications with sample marks with the various technologies.

We strive to better understand your requirements based on the industry specifications, product and/or substrates to be marked, the environment it is subject to, available budget and other expectations that apply. To better acquaint you to the product solutions and the limited ability to visit during these continued uncharted times, we are preparing a schedule of webinars with our vendors. If you want to be alerted to the workshops, please email [email protected]. Exciting things are in store in 2021 as Leading Marks continues to Identify Solutions to suit your needs.Happy New Year!

by Laurie Barcaskey Well, we’ve all heard it and hate the saying “but we’ve always done it that way.” Yes, I’m included in saying it, hearing it and resisting the thoughts of change at times but it’s inevitable and best if we embrace it and help make it happen.

Selling marking solutions is no different. I hear reasons like “I’m using Brand XYZ and they have always delivered”, or “it works for our needs right now.” Or even, "Well, it’s interesting but I’m not sure it fits our operation." And of course, "We’ve always done it this way."

Consider hand stamps for direct-part marking. Yes, it might be a caveman way of applying the mark and has its place in production. Let me ask a couple simple questions though.

Well maybe a quick solution is to add a hand stamp holder to make it a safer marking process. Maybe it’s time to consider adding a holder/type arrangement or dot peen marking system that would provide you more consistency not to mention versatility. Then again, maybe it’s using paint markers or stencils & ink rollers to apply text to beams, cartons or preformed concrete components. What a mess and waste of material. Talk about penmanship – what’s it going to be like in the future now that they don’t teach cursive writing in schools? Some of the newest technologies for applying ink marks are handheld, Bluetooth or computer-driven and are more environmentally friendly – not to mention economical in the long run by eliminating material waste or one-time use of stencils.

Well it’s cumbersome to rotate wheels around one character at a time – especially when you might have to make 50 to 100 of the same legend. Using proven, traditional components I’ve been able to take a new solution to an industry that wasn’t even looking. Every mark you make that the customer sees is reflective of your corporate image. Branding is a topic for another day. Yes, you can get inexpensive solutions on the internet, especially for commodity items like labels and rubber stamps. But do you get the service and support that offers alternatives with your company’s interest in mind? Oh I forgot, you’ve always worked with that company and don’t want to make the change. There’s that word again – change. I might not be the one you have worked with for years on your marking solutions. You might not have even been aware that there are experienced consultants out there to help offer suggestions for you to consider. Well there is, and I’m happy to schedule an appointment to review your marking process to see how it might be improved. Identifying solutions and improving processes are what I do. What is it you have been resisting to change? ABOUT THE AUTHOR:

Laurie Barcaskey of Leading Marks is an authorized manufacturer’s representative with 30 years of experience and shop floor knowledge of solutions for industrial identification, part traceability and pipe testing. Laurie is the third generation of one of the marking industry’s most innovative and enduring family legacies, tracing back to 1889. |

Follow us on LInkedIN for the latest breaking news!

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it. Archives

May 2024

Categories

All

|

RSS Feed

RSS Feed