|

by Laurie Barcaskey This article was originaly written for the NTMA newsletter If you are considering adding or upgrading your marking process, laser technology might serve you well. However, the investment requires doing some homework to ensure the system you choose will optimize your capabilities and allow room to grow. Whether looking for a dedicated workstation or integrating the marking into a production line, identifying the primary features to fit your budget need consideration. Finding the best partner to provide the solution becomes important. What one machine shop finds suitable for them does not always prove the best for another shop. Laser marking offers more flexible technology over chemical etching, which it most commonly replaces. Programming through the software provides the ability to quickly change marking details without having to print a mask specific to each marking file. Upgrading from dot peen can prove beneficial, however for applications where stress fractures might be a concern, you may want to think again. Understanding Marking Areas Within the laser marking solutions you will find different power sources that are specific to the types of materials you need to mark. Fiber sources are most suited for metals and some plastics, while CO2 sources best serve organic materials like wood, leather, and glass, along with some other plastics. Applications where heat may impact the product, or high contrast is needed there are other specialized laser sources such as UV, Green, Mopa and Solid State. When referring to laser marking systems, the "marking area" is the maximum surface area on which the laser can engrave, etch, or mark at one time. This area is crucial for determining the size of the designs or texts that can be applied without repositioning the material. The size of this marking area is largely determined by the lens that is used in the laser system. Standard Marking Area The industry standard for a marking area is often cited as 4 inches by 4 inches (approximately 102mm x 102mm). This size is suitable for a wide range of applications, offering a good balance between size and precision for many products and components. However, specific requirements can vary, and so laser systems are equipped with lenses that can offer both smaller and larger marking areas. Role of the Lens The lens in a laser marking system functions similarly to a lens in a camera or a magnifying glass. It focuses the laser beam to a precise point on the material's surface. The characteristics of the lens, including its focal length, determine the size of the marking area and how finely the laser can focus.

Impact on Focal Distance The focal distance is the distance between the lens and the material being marked. It is critical for achieving clear, precise marks:

Advantages of Laser Technology Having the ability to achieve different mark results based on program settings makes laser technology attractive. Ranging from a light surface etch to deep engraving, and annealed marking for contrast you can meet the demands of identification for a multitude of applications with one system – a job shops dream come true. There are quite a number of advantage of using laser technology:

Software and Usability Many of today’s lasers include user-friendly intuitive software that includes common navigation allowing beginners to get started quickly. This may include preloaded settings based on the type of material, preferred type of mark, and batch size. Typical marking details such as alpha/numeric characters and symbols are available in standard True Type fonts. The ability for marking bar codes increases to include 1D and 2D codes in a variety of formats, where programmable dot peen systems only allow for 2D codes. For more experienced laser programmers, the ability to access the background tools for deeper dives into the software may be the key factor when evaluating the software capabilities. Logo Importing and Data Entry Importing logos is a frequent request. Most lasers will accept standard formats such as .jpeg, .bitmap and .eps, however some software platforms may require files be converted to a specific format. Job shops looking to expand through contract marking may face time spent converting file formats from what customers provide to what the laser will accept. Entering the data into the software becomes important when the data changes often. To optimize the accuracy bar code scanning information from work orders removes transposing characters or placing data in the incorrect fields. Most software platforms will also allow entering data from spreadsheets optimizing throughput of items with multiple fields such as nameplates. Yet other times, interfacing with a host computer for data entry streamlines the data entry real-time. Workstation Types and Safety

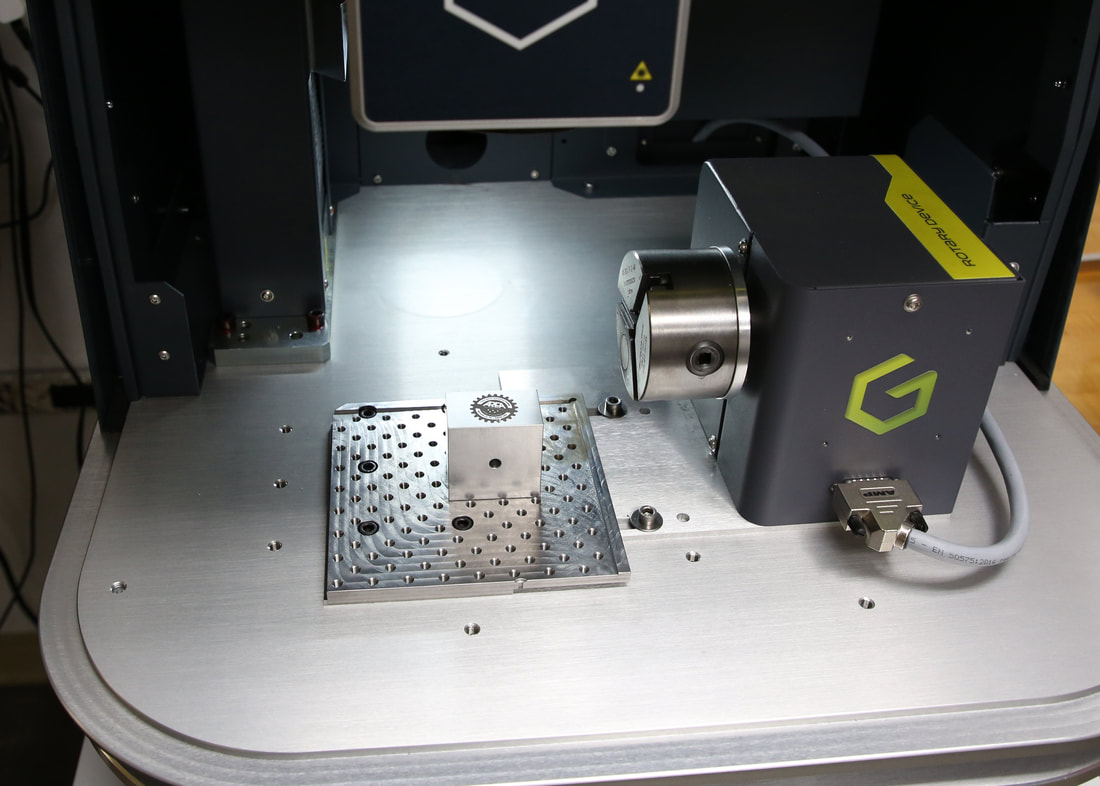

This leads to the types of workstations to consider, and safety is a key factor. For the sake of this article the focus is on a Galvo arrangement. A Galvo arrangement, short for "galvanometer arrangement," in the context of laser marking and engraving, refers to a system that utilizes galvanometer scanners to steer the laser beam across the target material's surface. These scanners contain mirrors that rapidly oscillate to reflect the laser beam in precise patterns, enabling the laser to etch, mark, or engrave with high speed and accuracy. This system contrasts with other types of laser positioning systems, such as gantry systems, which move the laser head or the workpiece mechanically over a fixed path. Sometimes Gantry style laser systems are more favorable for large batches of small parts. In Galvo arrangements Class I enclosed workstations meet OSHA standards for light-tight environments protecting the operators and area workers from stray beams. Laser providers typically offer a standard enclosure, and some can build a customized cabinet. Third-party automation organizations can also assist with custom enclosures and installations. Some key features of the enclosures to consider include the size and weight of parts being presented to the workstation, along with the access to the internal chamber. Manually operated, motorized and programmable doors are options with most laser suppliers. The ability to mark larger parts may require looking closely at the Z-axis, which is especially important to consider for proper focal distance. Options to automate the Z-axis are invaluable when part sizes change frequently and insure quick setup with accurate settings. While fixture requirements differ from impact marking, the tooling in laser applications assist with proper placement of the part for the marking process. Stability of the part during the marking process is more important than having it securely held. When available, T-slot bases offer the most flexibility for quick changeovers. Some shops choose to work without the enclosure in a Class IV arrangement. While these workstations offer greater flexibility with part sizes, they present the need for extra attention to safety in the area the laser is set up. The operator should be equipped with safety lens to suit the wavelength of the laser source. Preferably Class IV arrangements are placed in an area enclosed with laser safety barriers, if not in a room dedicated to laser marking. Maintenance and Partner Selection Another favorable feature of laser marking is the minimal maintenance requirements. By keeping the lens clean and the internal chamber of the enclosure free of debris and fumes from the marking process clear, legible mark results can be achieved consistently. A good air filtration system aids in this maintenance process. As you consider the partner for your project you want to explore the depth of their marking experience. Some partners are specific to laser marking, while others have a broader background in direct-part marking applications. The size of the organization will provide some indication of their ability to meet delivery and support post-sale issues. During the exploration period you will want to have test marking done on your materials and spend some time to be acquainted with their software. There are a lot of companies offering laser marking solutions, and like machine shops, they are not all the same. Choose wisely.

0 Comments

The Northwestern Pennsylvania (NWPA) Chapter of the National Tooling and Machining Association (NTMA), in collaboration with Northwest Industrial Resource Center (NWIRC) and NEFF Automation as the premier sponsor, is thrilled to announce two exclusive events to learn about the latest developments in the manufacturing industry. Join Leading Marks LLC on April 30th a Red Fern in Kersey, PA, and May 2nd in Erie, PA, at the Ambassador Center, for the Manufacturing Advanced Expo 2024. These events offer a unique platform for manufacturers and job shops to explore the latest advancements in automation technology, robotics, manufacturing processes, and their role in enhancing the skilled workforce in Northwest Pennsylvania. A Glimpse into Tomorrow’s Manufacturing With a focus on educational sessions that spotlight advanced technology and applications, attendees will gain invaluable insights into how the industry is evolving. Experts will delve into topics that are at the forefront of manufacturing innovation, including 3D Robotic Guidance, Deep Learning Machine Vision, Robotic Palletizing, Welding, and Machine Tending, as well as Industry 4.0 Solutions. These discussions are designed not only to inform but also to inspire action and innovation within your operations. Leading Marks Industrial Identification Graphix Laser Engraver: compact, space-saving, and easy to use in any workshop. Graphix Laser Engraver: compact, space-saving, and easy to use in any workshop. IN our view one of the highlights of the expo will be the display presented by Leading Marks LLC, a pioneer in industrial identification for the shop floor. With a focus on making processes more efficient while prioritizing safety, Leading Marks is will showcase the capabilities of the Technomark Graphix Laser Engravers. The Technomark Graphix Laser Engraver stands out for its versatility and efficiency. Designed to cater to the demanding needs of metals and plastics, this technology can be seamlessly integrated into manufacturing processes or operated as a stand-alone workstation. During the expo, Laurie Barcaskey, President of Leading Marks, will conduct live demonstrations, offering a unique chance for attendees to bring their samples for test marking. This interactive experience will provide a tangible understanding of how Leading Marks' solutions can elevate the productivity and safety of your shop floor. Aside from the laser part marking technology, Leading Marks LLC also offers a range of other marking technologies, including thermal transfer labeling, ink marking, and other traditional marking methods. This comprehensive approach ensures that every manufacturing need is met with the highest standards of quality and efficiency. Be Part of the |

| MANUFACTURING ADVANCED EXPO – KERSEY PA

| MANUFACTURING ADVANCED EXPO – ERIE PA

|

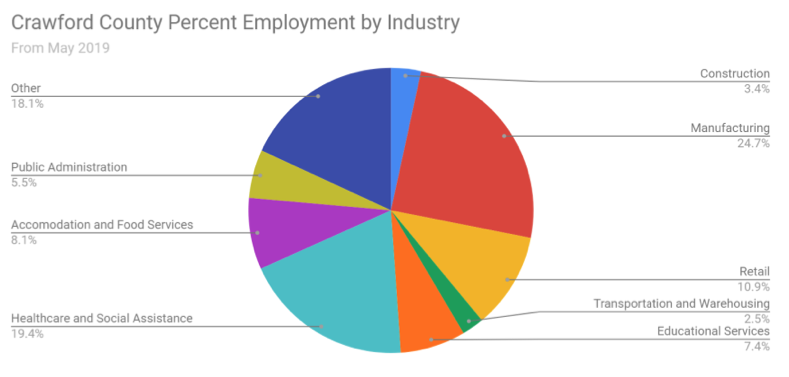

Meadville is located in Northwestern Pennsylvania and is the bedrock of the Crawford County economy, accounting for about a quarter of employment in the county. And those the jobs in the country are pretty much all in tool & die manufacturing!

Today, the Meadville area remains a leader in tooling, machining and advance manufacturing and the city serves as the region’s center for banking, education and social services.”

A recent study undertaken at Allegheny College entitled , Trends in the Tooling and Machining Industry of Crawford County, Pennsylvania states, "Starting in the early 20th century, the Talon Company started the production of area toolmakers. Through their apprenticeship programs, workers learned the art of toolmaking. Many workers at Talon spun off to create their own companies. Since then, the tooling and machining industry has helped sustain the county as a major source of employment, revenue generator, and an important factor in the vibrancy of the real estate and retail sectors."

Today Meadville is home to numerous small, medium and large tool and die shops, and is a leader in precision machining, plastic injection molding and aerospace engineering.

"The industry is now transitioning to a third generation set of owners, who bring new attributes to the industry... For the first time in the history of the industry, women are either the CEOs or operations managers of an increasing number of tool shops."

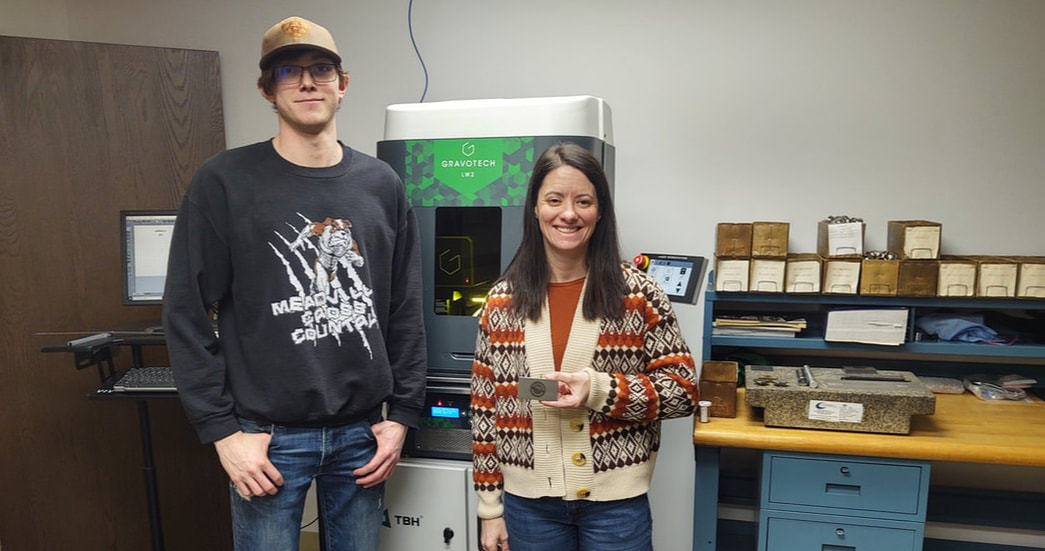

Area Tool & Manufacturing, Inc. certainly fits that description as a second generation woman owned family business, as it's now solely owned by Ashleigh Wehrle. Area Tool's TEAM consists of 13 employees with an average of 30 years of experience in the spare parts and mold industries and many of the shop floor employees are journeymen toolmakers. It's located just a few minutes from the Interstate 79 interchange in a 20,000 square foot climate-controlled building.

"Part buyers and engineers often assume they can save time and money on an assembly project by sourcing the components that make up their assembly from multiple shops. But the truth is that when more than one shop is responsible for precision machining as many as 100 components for a large assembly, issues with tolerance and fitment are common. The worst part? These problems remain hidden until the shipments arrive at your door. It’s only then that you discover that the components don’t fit together and the assembly doesn’t function properly."

|

That philosophy is put into practice according to Ashleigh Wehrle "We had historically used a local subcontract shop for our laser engraving needs. Our partner was very responsive to our needs and a pleasure to work with, but ultimately we were looking for an in-house solution."

Laurie Barcaskey, President of Leading Marks LLC, introduced herself and her company to Wehrle in the Spring of 2015. "We were evaluating equipment needs within our facility. We were mostly interested in laser marking solutions that Laurie could offer." Wehrle continues, "We were pleased with the solutions Laurie presented however chose to invest in larger equipment purchases that had taken priority." |

|

As a small shop, you have to pick and choose which area to invest your capital and then prioritize the order of that in investment. Sometimes it takes a few years.

Wehrle continues, "We revisited the need for in-house laser marking in the fall of 2021. We often times found parts would be ready to ship late in the day except for the laser engraving requirement."

That's a big problem for a machine shop that prides itself on meeting and exceeding delivery requirements.

"One of our customers had a part scheduled to ship overnight, but they needed it sooner, so they asked, “Could you get someone on a flight tonight?” That same evening, an Area Tool team member flew to Boston and hand-delivered the part to the customer. Requests like this one aren’t feasible for OEMs. But because of our size, we can tailor our services to customers’ unique needs." said Wehrle

"The GravoTech solution with rotary head was a perfect fit for the low volume mill and lathe parts we manufacture. We are also able to label in house fixturing and tooling for better organization. We have also replaced our dot peen for marking to provide a customers with more professional marking." said Wehrle.

To sum it all up Wehrle says "Having the capabilities in house allows us to laser engrave and ship the parts 2-3 days sooner than if we continued to outsource." Automation continues to be embraced at every size machine shop as qualified labor continues to become more difficult to find.

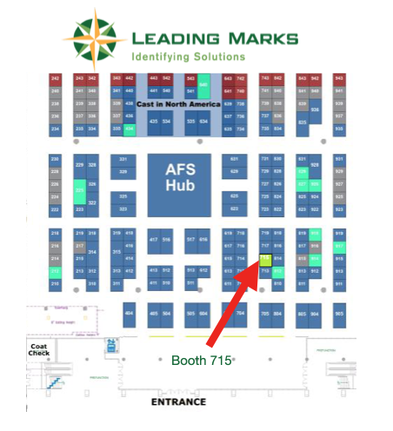

Nestled along Lake Erie’s southern shore, Cleveland is the second largest city in Ohio. Huntington Convention Center of Cleveland is hosting Metalcasting Congress 2023, providing over 410,000 square feet of prime meeting and event space. The convention center is also just 25 minutes away from Cleveland Hopkins International Airport.

Leading Marks & Boss Buddy

Booth 715

| We will also be showcasing secondary marking requirements with direct-part marking systems and tools such as dot peen, laser & stamps, ink marking, hand-held & automated systems, and thermal transfer labeling solutions. We will also be discussing workbenches, air filtration, vision handheld scanners and in-line options, soldering irons, and machining accessories. Huntington Convention Center Cleveland, OH April 25 – 27, 2023 Leading Marks Booth 715 |

There are several types of laser marking, including annealing, engraving, and foaming. The type of laser used, the material being marked, and the desired outcome will determine the specific process and technique used for laser marking.

Common materials that can be laser marked include metals, plastics, and ceramics. Laser marking is often used in industrial settings for product identification, traceability, and branding.

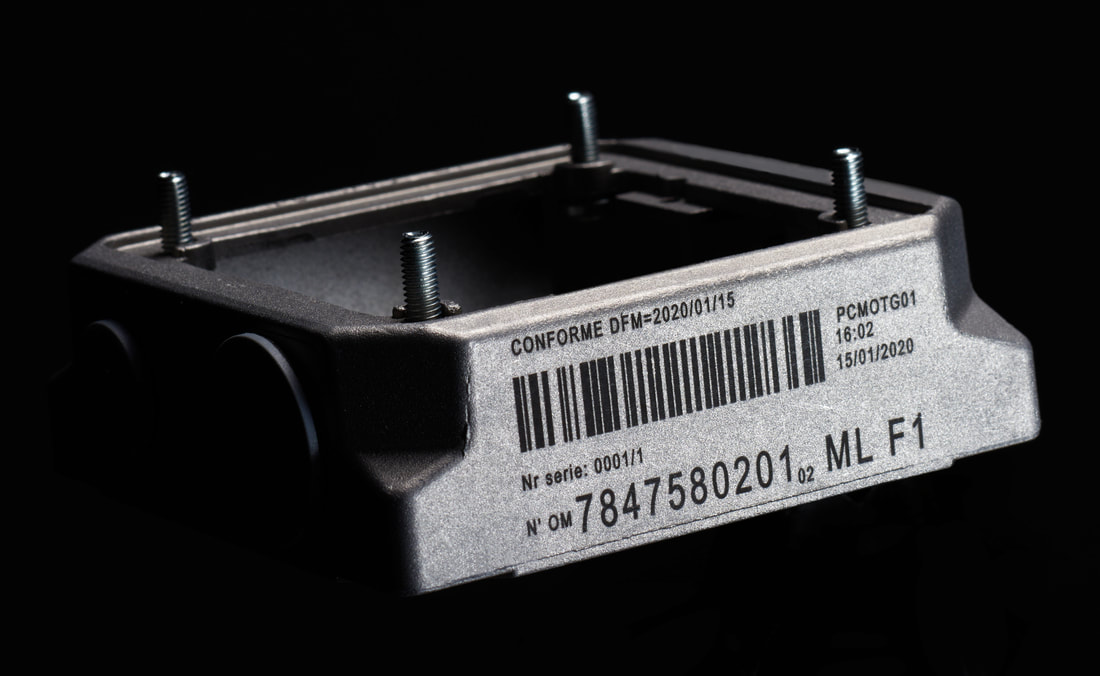

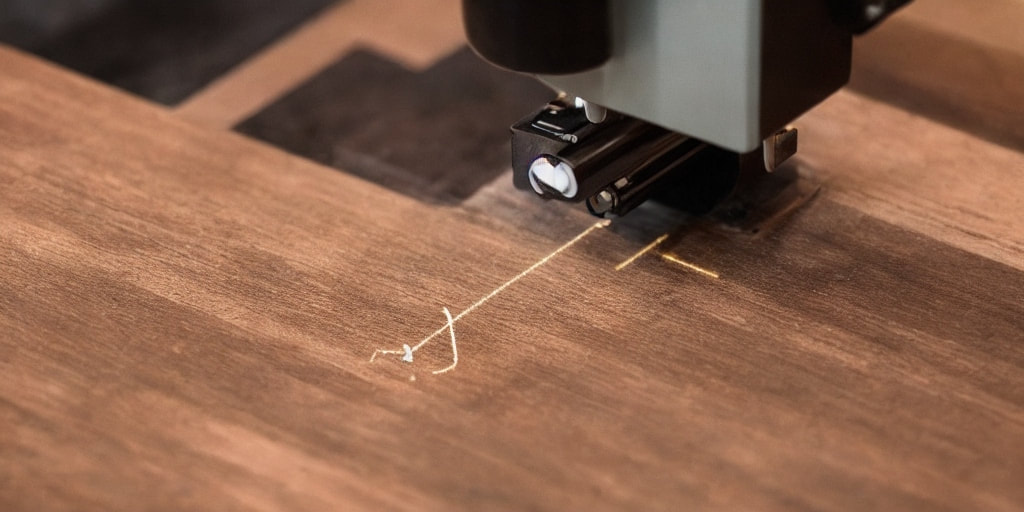

The principle of industrial traceability by laser engraving is based on a beam of high intensity laser focused and then directed towards the part to be marked. Its orientation is ensured by a galvanometric head composed of two mirrors. When a laser beam hits a part's surface, the energy is transferred in the form of heat, creating black, white, and sometimes colored marks.

In manufacturing, Lasers are a permanent, a precise and qualitative marking solution for part identification and traceability. Different applications may require different marking techniques such as engraving, staining, removing, annealing, and foaming are the most common marking methods. Each laser marking procedure will have its own unique advantages and disadvantages, depending on the materials being used and the quality requirement.

Types of Materials to Laser Mark

- Metals: Stainless steel, aluminum, brass, and titanium are common materials that can be laser marked. The laser beam melts or vaporizes the metal, creating a permanent mark.

- Plastics: Many different types of plastics can be laser marked, including polycarbonate, ABS, and polyamide. The laser beam causes the surface of the plastic to change color, creating a contrast between the marked and unmarked areas.

- Ceramics: Ceramic materials can be laser marked by removing a thin layer of the surface material. This creates a contrast between the marked and unmarked areas, making the mark visible.

- Glass: Laser marking on glass is done by a process called scribing, which involves using a laser beam to create a crack in the surface of the glass.

- Wood: Wood materials can be laser marked by burning the surface of the wood, resulting in a dark mark on a light background.

- Some fabrics: Laser marking can be used to print on fabrics such as denim, cotton, polyester, etc.

What Kinds of Marks

Laser marking can be used to create a variety of marks, including:

- Text: Laser marking can be used to engrave text, such as product information, serial numbers, or branding, onto the surface of an object.

- Barcodes and QR codes: Laser marking can be used to create barcodes and QR codes, which can be used for product identification and tracking.

- Logos and graphics: Laser marking can be used to engrave logos and graphics onto the surface of an object, such as company logos or product images.

- Serial numbers: Laser marking can be used to engrave serial numbers onto the surface of an object, which can be used for product identification, tracking, and traceability.

- Data matrix codes: Laser marking can be used to create Data matrix codes, which are a type of two-dimensional barcode that can store a large amount of information in a small space.

- Deep engraving: This type of laser marking is used to create three-dimensional marks in the surface of an object, and can be used to create detailed images or text.

- Cutouts and shapes: Laser cutting can be used to create intricate cuts and shapes in materials, such as fabrics, plastics, metals and even wood.

- Micro-text: Laser marking can be used to create very small text that is difficult to read with the naked eye, but can be read with a microscope.

Types of Laser Marking

- Annealing: This type of laser marking involves using a laser beam to heat a metal surface, causing a change in the color of the metal. This type of marking is often used on stainless steel and titanium.

- Engraving: This type of laser marking involves removing a small amount of material from the surface of an object, creating a permanent mark. This type of marking is often used for product identification, traceability, and branding.

- Foaming: This type of laser marking involves using a laser beam to create small bubbles on the surface of a plastic material, creating a contrasting mark. This type of marking is often used for product identification, traceability, and branding.

- Scribing: This type of laser marking involves using a laser beam to create a crack in the surface of a material such as glass. This type of marking is often used for product identification, traceability, and branding.

- Ablating: This type of laser marking involves using a laser beam to remove a small amount of material from the surface of an object, creating a permanent mark. This is commonly used in the aerospace, automotive, and medical device industries for product identification, traceability, and branding.

- Color change: This type of laser marking involves using a laser beam to change the color of the surface of a material. This is commonly used in the packaging and labeling industry for product identification, traceability, and branding.

- Deep engraving: This type of laser marking is used to create three-dimensional marks in the surface of an object, and can be used to create detailed images or text.

- Laser cutting: This type of laser marking involves using a laser beam to cut materials, such as fabrics, plastics, metals and even wood.

- The type of laser marking that is used will depend on the material being marked and the desired outcome.

What Industries is Laser Marking Most Commonly Used?

- Manufacturing: Laser marking is commonly used in the manufacturing industry for product identification, traceability, and branding. This includes marking product information, serial numbers, and company logos onto the surface of products.

- Aerospace and Defense: Laser marking is used in the aerospace and defense industries for product identification and traceability, such as marking serial numbers and other information onto aircraft parts.

- Automotive: Laser marking is used in the automotive industry for product identification and traceability, such as marking serial numbers and other information onto car parts.

- Medical Device: Laser marking is used in the medical device industry for product identification and traceability, such as marking serial numbers and other information onto medical devices.

- Electronics: Laser marking is used in the electronics industry for product identification and traceability, such as marking serial numbers and other information onto electronic devices.

- Jewelry: Laser marking is used in the jewelry industry for product identification and traceability, such as marking serial numbers and other information onto jewelry.

- Packaging and labeling: Laser marking is used in the packaging and labeling industry for product identification and traceability, such as marking serial numbers and other information onto packaging and labels.

- Textile: Laser marking is used in the textile industry for product identification and traceability, such as marking serial numbers and other information onto fabrics.

- Wood and stone: Laser marking is used in the wood and stone industry for product identification and traceability, such as marking serial numbers and other information onto wood and stone products.

Thomas Erie, Inc. is part of the Thomas Group, the world’s largest independent supplier of tinplate and aluminum components for the aerosol, pharmaceutical and cosmetic industry. The Thomas Group employ 500 people worldwide. They produce stamped and deep drawn parts on progressive tools and transfer presses in Germany, the USA, Spain, China and Argentina.

Foster explained, " We originally purchased an Automator Laser Engraver for marking our parts only for identification purposes. One day shortly after purchasing the engraver we found ourselves with a rush order for some debossed parts and the vendor we typically purchase our graphite anodes from could not meet our customer’s timeline. "

"We don't have a high speed mill able to make the fine detail on the anodes required to meet our customer specifications and typically outsource this item. We were able to utilize the laser engraver to cut the graphite anode and then using our EDM sinker make our own debossing tool with laser point accuracy." said Foster, "This cut our lead time down from weeks to minutes and eliminated the cost of outsourcing completely."

Foster found Leading Marks' Laurie Barcaskey very helpful. "Laurie offers good pricing, provides good service and is able to answer our questions. We would recommend her for your next project!"

Get in touch with Laurie with any questions!

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it.

Archives

May 2024

April 2024

March 2024

February 2024

January 2024

December 2023

November 2023

October 2023

September 2023

August 2023

July 2023

June 2023

May 2023

April 2023

March 2023

February 2023

January 2023

November 2022

October 2022

September 2022

August 2022

July 2022

May 2022

March 2022

December 2021

November 2021

September 2021

August 2021

July 2021

May 2021

March 2021

February 2021

January 2021

December 2020

July 2020

June 2020

May 2020

April 2020

March 2020

February 2020

January 2020

December 2019

November 2019

October 2019

September 2019

August 2019

July 2019

June 2019

April 2019

March 2019

January 2019

December 2018

November 2018

October 2018

September 2018

August 2018

July 2018

June 2018

May 2018

April 2018

March 2018

February 2018

January 2018

December 2017

October 2017

September 2017

July 2017

June 2017

May 2017

April 2017

December 2016

September 2016

August 2016

July 2016

June 2016

May 2016

April 2016

February 2016

January 2016

August 2015

October 2014

July 2010

Categories

All

AFS Medtalcasting Congress

AFS Pittsburgh

Area Tool

Arromark

Automator

Benson Foundry

Bepop

BizMix

Boss Buddy

Bots IQ

Case Study

Cembre

Clamping

Covid

Date Codes

Design 2 Part

Direct Part Marking (DPM)

Dot Peen

Durable Mecco

EBS Ink Jet

Embossing Dies

Flexpak

Foundry Society

Foundry Solutions

Fundamentals

Gravotech

Handjet

Handstamp

Hexacon

HFO Demo Day

Honeywell

Hot Stamping

IMTS

ITT Gould Pumps

JetStamp

Labeling

Laser Marking

Laurie Barcaskey

Leading Marks

LEDLenser

Manufacturing Expo

Marking

Marking Indsutry Magazine

Max USA

Mfg Advanced Expo

MFG Day

Mitee Bite

Modern Casting

Modern Machine Shop

Nameplates

NTMA

OSHA Compliance

Pitt Chem Day

Presentations

Promotions

Reiner

Reiner Jetstamp 1025

Rising Rust Belt

Roll Dies

Scanners

SDS & MSDS

Signage

Stamping Press

Steel Stamps

Supply Chain

Tags

Tapmatic

Tapmatic MH Marking Head

TBH

TBH BF -Series

TBH GL-Series

Tech Article

Technifor

Technomark

Testimonials

Thermal Printing

Traceability

Trade Shows

Unique Device Identification (UDI)

Videos

WBENC - Women’s Business Enterprise National Council

WBE Women’s Business Enterprise

WBE - Women’s Business Enterprise

Workholding

WOSB - Women Owned Small Business

Zuess Marking

RSS Feed

RSS Feed