|

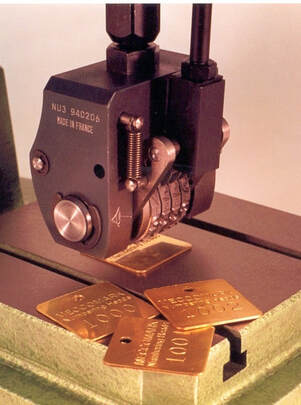

Technomark Easy connect hand held dot peen is a portable, wireless, energy self-sufficient, network-connected dot peen machine. compiled & written by Bernard Martin "We found out about Leading Marks through the web. We contacted Laurie and she did a great presentation and was able to teach the system during the sales call. One of the things we liked best about working with Laurie is her expertise, She knows her products and their capabilities thoroughly." says Ed DeMailo, General Manager, at MetalWerks Inc.  Metalwerks dot peen sample Metalwerks dot peen sample Metalwerks, Inc. has over twenty years of experience melting and processing vacuum melted specialty metals. They operate five vacuum melting furnaces and bar processing equipment at their facilities in Aliquippa, PA. Metalwerks serve customers in the medical, industrial, and aerospace industries as well as research and development projects. Typically alloy systems at Metalwerks include Fe, Ni, Co, Cu, Ti, and Zr in quantities ranging from 300 grams up to 6000 pounds. Through their network of outside processors they convert ingot into bar, plate, coil and/or sheet. "The Easy, the Dot Peen marking system offers an unrivaled level of functionality. Being easy to use while delivering an exceptional operating experience to the user. Easy is ideal for mobile use, since the unique and durable, yet the lightweight chassis allows a user to mark medium to large parts in even the most difficult and inaccessible locations." said Laurie Barcskey, owner of Leading Marks, LLC. "The dot peen marking system has served us quite well: No more smashed fingers, Clarity of the letters, and no problem training operators." says DeMailo. I would recommend Leading Marks to other companies because they really understand and know their equipment. They are great to work with !!!!" If you have any questions about portable dot peen marking solutions, get in contact with Laurie!

0 Comments

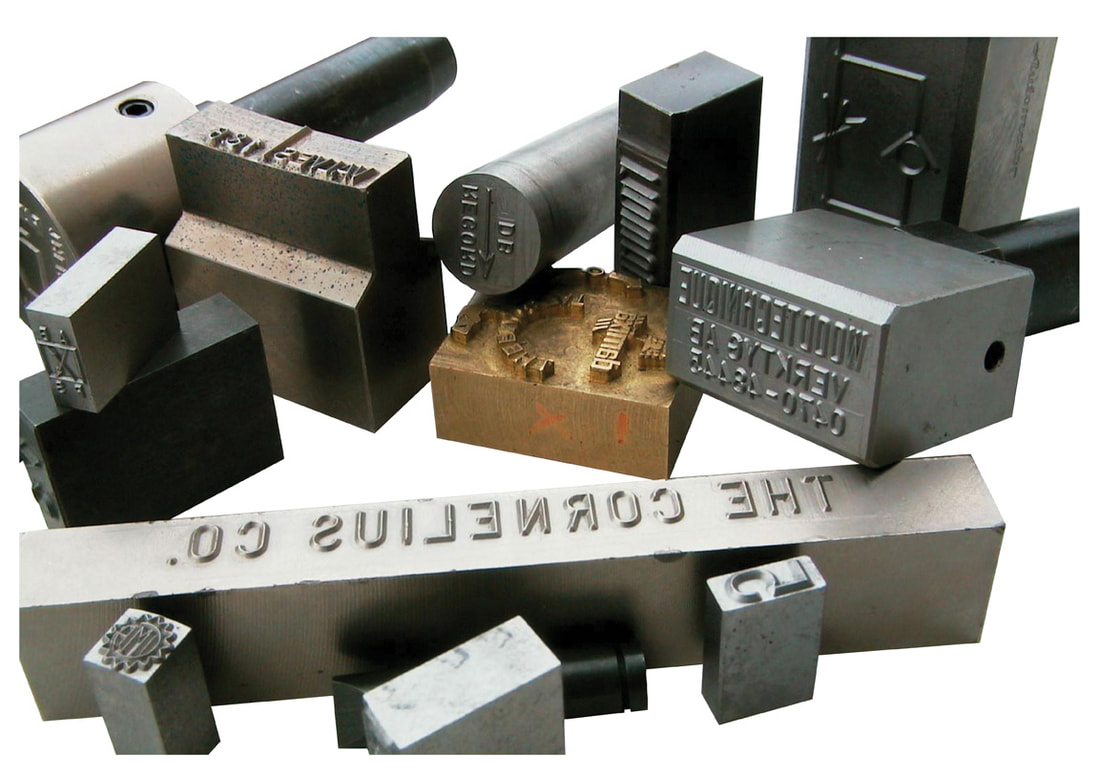

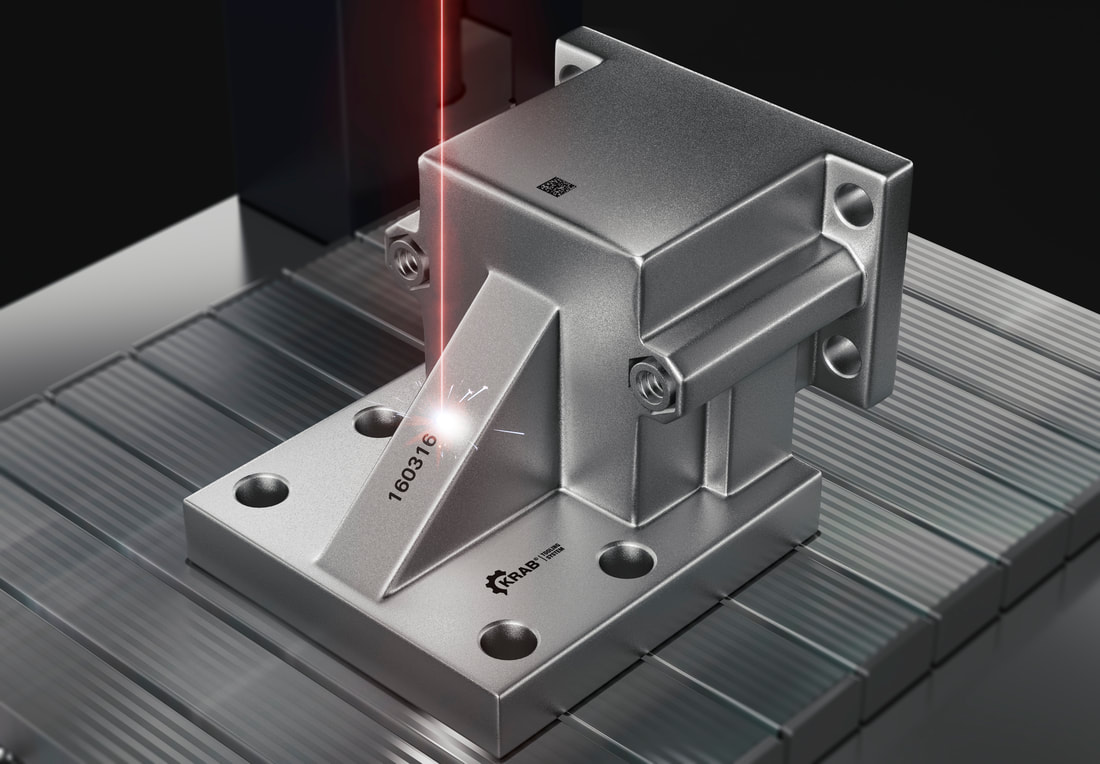

Marking 5 Lines of Code on Precast Concrete: Oil Crayons Versus EBS-260 Hand-Held Inkjet Printer The HandJet EBS 260 provides reimagined features and functionality for even more innovative, portable coding. The EBS-260’s print height has been doubled to 32 dots with print heights up to 2.2″ and will provide one to four separate lines of code. EBS has increased the capacity of the ink cartridge to up to 200,000 characters in a 7×5 matrix. Single- or multi-line messages from .276″ to 2.2″ high can be printed on both porous and non-porous substrates. It’s ideal for imprinting corrugated, paper, film, foil, glass, metal, lumber, concrete, and many other surfaces. At slightly-over 3.5-lb. the unit features a new redesigned hand grip improved ergonomic grip contours to ensure that handling is comfortable and well- balanced. In the video below, the portable, lightweight EBS-260 marks a 2.2” high pre-programmed text and the printer's built-in laser guidance ensure precise message positioning. The EBS-260 features a touch-screen controller, with a 3.5"-diagonal, hardened screen, enables the user to view the message being printed and make on-the-fly text adjustments. A big thank you to Oldcastle Infrastructure, an industry leader in engineered building solutions, in Elgin, IL. for this video. In essence, Direct Part Marking (DPM) is applying identification that lasts from cradle to grave and will sustain very rugged environments. Many US government agencies are making unique device identification (UDI) and direct part marking (DPM), mandatory. The private sector, from automotive manufacturers to medical offices have been using DPM more and more as they have embraced the Deming Principles of TQM. Direct Part Marking is used most frequently when marks are needed on a variety metals, plastics and wood. Common equipment solutions range from traditional hand stamping processes to cutting edge technology of fiber laser marking. Direct part marking is often a less costly alternative to purchasing RFID tags. When to Choose Direct Part Marking

Direct Part Marking Options

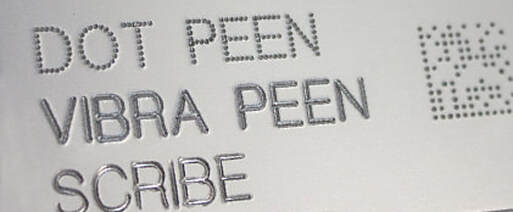

2D Codes: Most Popular for Direct Part Marking In most cases, direct part marking applications use two-dimensional (2D) barcodes such as Datamatrix or QR Code, which carry much more data than linear (1D) barcodes. By using 2D barcodes, manufacturers can also identify very small items and parts.  Dot Peen vs Vibra Peen vs Scribe and a 2D QR code Dot Peen vs Vibra Peen vs Scribe and a 2D QR code 2D codes can pack a large amount of data as opposed to linear codes because they can carry data in two directions on the code vs. just one. To give you an idea of the relative size, a 1D barcode can store around 25 characters up to about 80 characters depending on whether it’s Code 128 or Code 39, but a 2D code can store up to 2,000 characters. In the automotive sector, there is an established standard (AIAG B11) for direct part marking, and a number of large auto OEMs like Ford require suppliers of certain components to use DPM for part traceability. Manufacturers like to use the 2D code not only for the storage capacity, but for their relative size as well (square vs. rectangular). The flexibility of a 2D code allows for the variation in the amount of information stored in the barcode as well as the size of the item being marked. The most popular uses of the mark are for applications that require:

Thomas Erie, Inc. is a Girard, PA based company that produces quality metal stamped parts. They serve markets such as electronics, automotive and aerospace Their capabilities include stampings from 0.25 to 0.55 mm, Gasketing, embossing & anodizing. Thomas Erie, Inc. is part of the Thomas Group, the world’s largest independent supplier of tinplate and aluminum components for the aerosol, pharmaceutical and cosmetic industry. The Thomas Group employ 500 people worldwide. They produce stamped and deep drawn parts on progressive tools and transfer presses in Germany, the USA, Spain, China and Argentina. "We have been working with Laurie Barcaskey since 2014." said Foster Nickel the Toolroom Manger.

Foster explained, " We originally purchased an Automator Laser Engraver for marking our parts only for identification purposes. One day shortly after purchasing the engraver we found ourselves with a rush order for some debossed parts and the vendor we typically purchase our graphite anodes from could not meet our customer’s timeline. " "We don't have a high speed mill able to make the fine detail on the anodes required to meet our customer specifications and typically outsource this item. We were able to utilize the laser engraver to cut the graphite anode and then using our EDM sinker make our own debossing tool with laser point accuracy." said Foster, "This cut our lead time down from weeks to minutes and eliminated the cost of outsourcing completely." Foster found Leading Marks' Laurie Barcaskey very helpful. "Laurie offers good pricing, provides good service and is able to answer our questions. We would recommend her for your next project!" Get in touch with Laurie with any questions! Join Leading Marks Founder, Laurie Barcaskey and the Pittsburgh Business Times to mix, mingle and network with Pittsburgh business professionals at BizMix at an evening networking reception. This event will be held in the second floor private event space at Roland's Seafood Grill in the Strip District.

Would you like to discuss your current marking projects with Leading Marks? Laurie will he talking about industrial strength solutions for

Your reservation includes:

|

Follow us on LInkedIN for the latest breaking news!

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it. Archives

May 2024

Categories

All

|

RSS Feed

RSS Feed