|

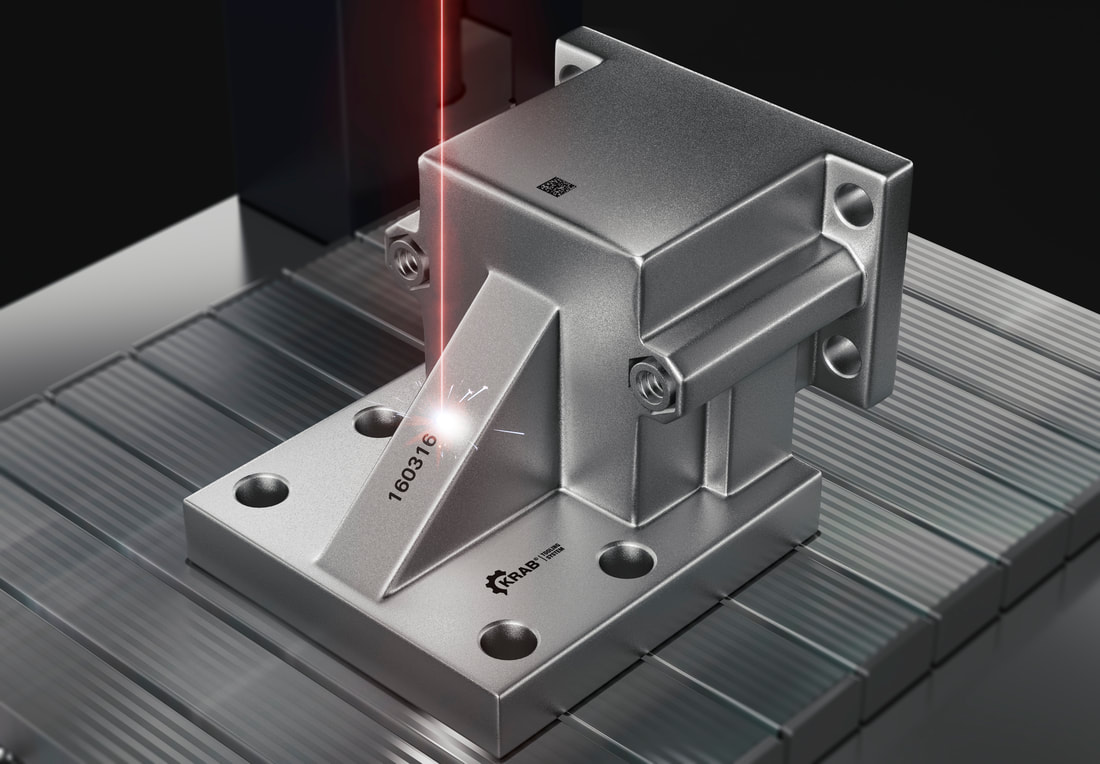

by Laurie Barcaskey This article was originaly written for the NTMA newsletter If you are considering adding or upgrading your marking process, laser technology might serve you well. However, the investment requires doing some homework to ensure the system you choose will optimize your capabilities and allow room to grow. Whether looking for a dedicated workstation or integrating the marking into a production line, identifying the primary features to fit your budget need consideration. Finding the best partner to provide the solution becomes important. What one machine shop finds suitable for them does not always prove the best for another shop. Laser marking offers more flexible technology over chemical etching, which it most commonly replaces. Programming through the software provides the ability to quickly change marking details without having to print a mask specific to each marking file. Upgrading from dot peen can prove beneficial, however for applications where stress fractures might be a concern, you may want to think again. Understanding Marking Areas Within the laser marking solutions you will find different power sources that are specific to the types of materials you need to mark. Fiber sources are most suited for metals and some plastics, while CO2 sources best serve organic materials like wood, leather, and glass, along with some other plastics. Applications where heat may impact the product, or high contrast is needed there are other specialized laser sources such as UV, Green, Mopa and Solid State. When referring to laser marking systems, the "marking area" is the maximum surface area on which the laser can engrave, etch, or mark at one time. This area is crucial for determining the size of the designs or texts that can be applied without repositioning the material. The size of this marking area is largely determined by the lens that is used in the laser system. Standard Marking Area The industry standard for a marking area is often cited as 4 inches by 4 inches (approximately 102mm x 102mm). This size is suitable for a wide range of applications, offering a good balance between size and precision for many products and components. However, specific requirements can vary, and so laser systems are equipped with lenses that can offer both smaller and larger marking areas. Role of the Lens The lens in a laser marking system functions similarly to a lens in a camera or a magnifying glass. It focuses the laser beam to a precise point on the material's surface. The characteristics of the lens, including its focal length, determine the size of the marking area and how finely the laser can focus.

Impact on Focal Distance The focal distance is the distance between the lens and the material being marked. It is critical for achieving clear, precise marks:

Advantages of Laser Technology Having the ability to achieve different mark results based on program settings makes laser technology attractive. Ranging from a light surface etch to deep engraving, and annealed marking for contrast you can meet the demands of identification for a multitude of applications with one system – a job shops dream come true. There are quite a number of advantage of using laser technology:

Software and Usability Many of today’s lasers include user-friendly intuitive software that includes common navigation allowing beginners to get started quickly. This may include preloaded settings based on the type of material, preferred type of mark, and batch size. Typical marking details such as alpha/numeric characters and symbols are available in standard True Type fonts. The ability for marking bar codes increases to include 1D and 2D codes in a variety of formats, where programmable dot peen systems only allow for 2D codes. For more experienced laser programmers, the ability to access the background tools for deeper dives into the software may be the key factor when evaluating the software capabilities. Logo Importing and Data Entry Importing logos is a frequent request. Most lasers will accept standard formats such as .jpeg, .bitmap and .eps, however some software platforms may require files be converted to a specific format. Job shops looking to expand through contract marking may face time spent converting file formats from what customers provide to what the laser will accept. Entering the data into the software becomes important when the data changes often. To optimize the accuracy bar code scanning information from work orders removes transposing characters or placing data in the incorrect fields. Most software platforms will also allow entering data from spreadsheets optimizing throughput of items with multiple fields such as nameplates. Yet other times, interfacing with a host computer for data entry streamlines the data entry real-time. Workstation Types and Safety

This leads to the types of workstations to consider, and safety is a key factor. For the sake of this article the focus is on a Galvo arrangement. A Galvo arrangement, short for "galvanometer arrangement," in the context of laser marking and engraving, refers to a system that utilizes galvanometer scanners to steer the laser beam across the target material's surface. These scanners contain mirrors that rapidly oscillate to reflect the laser beam in precise patterns, enabling the laser to etch, mark, or engrave with high speed and accuracy. This system contrasts with other types of laser positioning systems, such as gantry systems, which move the laser head or the workpiece mechanically over a fixed path. Sometimes Gantry style laser systems are more favorable for large batches of small parts. In Galvo arrangements Class I enclosed workstations meet OSHA standards for light-tight environments protecting the operators and area workers from stray beams. Laser providers typically offer a standard enclosure, and some can build a customized cabinet. Third-party automation organizations can also assist with custom enclosures and installations. Some key features of the enclosures to consider include the size and weight of parts being presented to the workstation, along with the access to the internal chamber. Manually operated, motorized and programmable doors are options with most laser suppliers. The ability to mark larger parts may require looking closely at the Z-axis, which is especially important to consider for proper focal distance. Options to automate the Z-axis are invaluable when part sizes change frequently and insure quick setup with accurate settings. While fixture requirements differ from impact marking, the tooling in laser applications assist with proper placement of the part for the marking process. Stability of the part during the marking process is more important than having it securely held. When available, T-slot bases offer the most flexibility for quick changeovers. Some shops choose to work without the enclosure in a Class IV arrangement. While these workstations offer greater flexibility with part sizes, they present the need for extra attention to safety in the area the laser is set up. The operator should be equipped with safety lens to suit the wavelength of the laser source. Preferably Class IV arrangements are placed in an area enclosed with laser safety barriers, if not in a room dedicated to laser marking. Maintenance and Partner Selection Another favorable feature of laser marking is the minimal maintenance requirements. By keeping the lens clean and the internal chamber of the enclosure free of debris and fumes from the marking process clear, legible mark results can be achieved consistently. A good air filtration system aids in this maintenance process. As you consider the partner for your project you want to explore the depth of their marking experience. Some partners are specific to laser marking, while others have a broader background in direct-part marking applications. The size of the organization will provide some indication of their ability to meet delivery and support post-sale issues. During the exploration period you will want to have test marking done on your materials and spend some time to be acquainted with their software. There are a lot of companies offering laser marking solutions, and like machine shops, they are not all the same. Choose wisely.

0 Comments

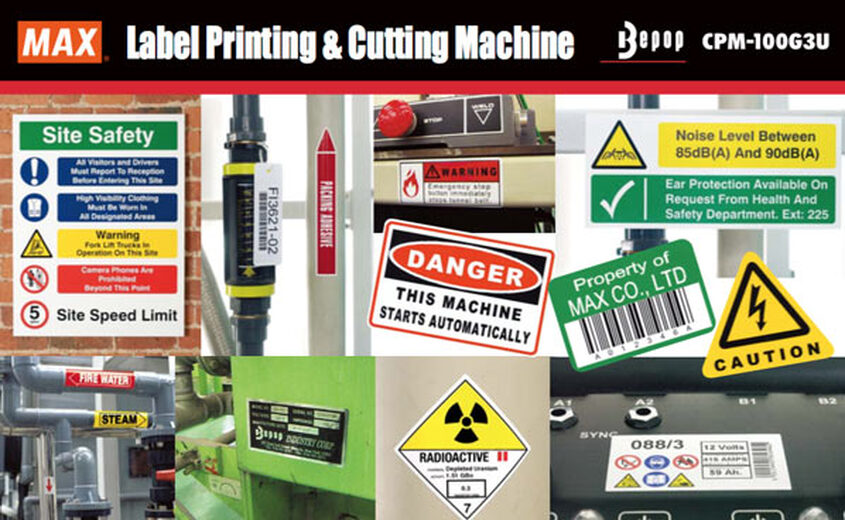

Machines that Make the Signs for the Times Whether it is the elegant requirements of architectural signs, meeting ADA (Americans with Disabilities ACT) wayfinding requirements, or durable safety signs that survive rugged environments how you make the sign matters. Leading Marks is an authorized distributor of the GravoTech engraving systems and the MAX USA Bepop 4-color thermal printers. Specializing in identification requirements, Leading Marks believes in presenting options that allow the customer options to meet the expectations of the job and work within the available budget for the capital investment. Engraving MachinesGravoTech, a leader of direct part marking machinery, offers a complete line of rotary and laser engraving machines. The rotary systems come in compact units for simple tasks of creating small legend plates, switch plates and more.

Thermal PrintersSafety signage and labeling is a critical part of the safety process for manufacturing and construction alike — especially for specialty contractors such as electrical and mechanical. ANSI and OSHA requirements give guidelines to help identify areas where danger or caution should be exercised during operation and/or maintenance of equipment.

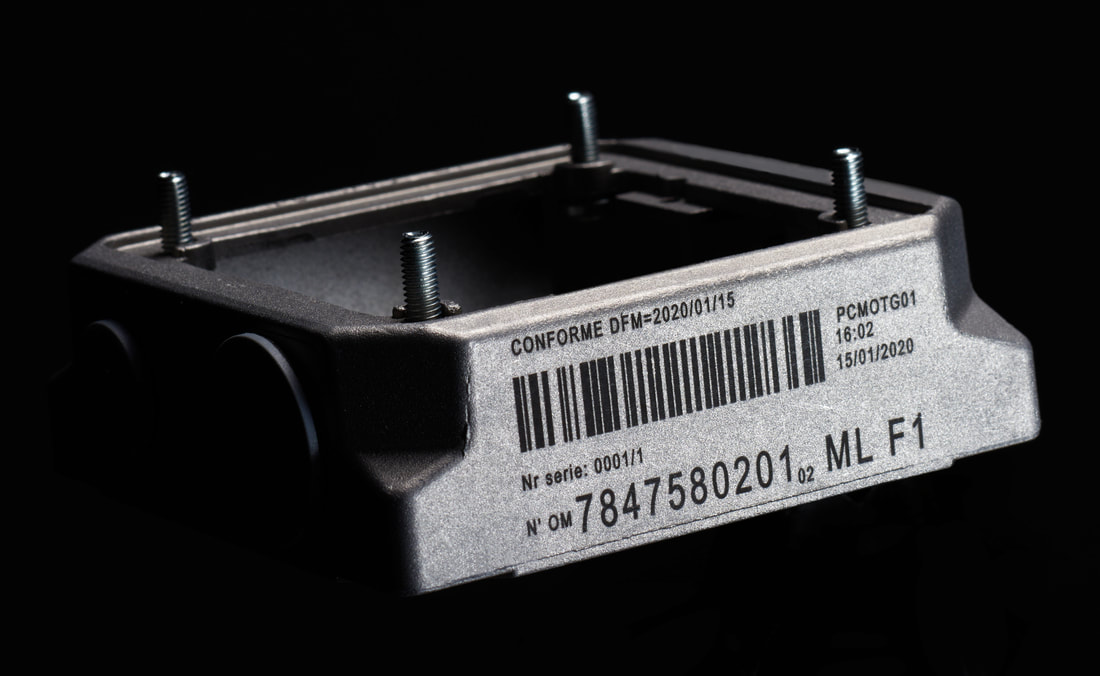

The 4-color MAX USA Bepop printers are available in two sizes: 4” and 8”. An investment in either machine allows you to make signs on-demand. They even allow you to cut to size. Signs to GoIf you are not sure investing in capital equipment for your label and sign needs makes sense, Leading Marks also provides stocked and made-to-order solutions too. When these needs arise, it is always helpful to understand your needs. It is also helpful to know the environment for which the label and sign will be used, and the driving need for it. With this information we can recommend the applicable material the sign should be made of meeting ANSI and OSHA requirements. Artwork in digital format expedites the ability to respond quickly. Common standard and customized signs are available for biohazard and hazardous materials, safety, first aid, lockout tagout, machine operation and personal protection. Even rugged applications for aerial, pipelines, substations, traffic signals and other rugged industrial or construction site requirements. Created via Chat GPT, Edited by Bernard Martin Laser marking is a process in which a laser beam is used to mark or engrave an object. The laser beam is directed at the surface of the object, and the energy from the beam causes a change in the surface material, resulting in a permanent mark. There are several types of laser marking, including annealing, engraving, and foaming. The type of laser used, the material being marked, and the desired outcome will determine the specific process and technique used for laser marking. Common materials that can be laser marked include metals, plastics, and ceramics. Laser marking is often used in industrial settings for product identification, traceability, and branding. The term "laser" stands for "Light Amplification by Stimulated Emission of Radiation," which summarizes quite well exacty how lasers work. Light particles, called photons, are excited with an electrical current, causing them to emit energy in the form of light. This light forms the laser beam. The principle of industrial traceability by laser engraving is based on a beam of high intensity laser focused and then directed towards the part to be marked. Its orientation is ensured by a galvanometric head composed of two mirrors. When a laser beam hits a part's surface, the energy is transferred in the form of heat, creating black, white, and sometimes colored marks. In manufacturing, Lasers are a permanent, a precise and qualitative marking solution for part identification and traceability. Different applications may require different marking techniques such as engraving, staining, removing, annealing, and foaming are the most common marking methods. Each laser marking procedure will have its own unique advantages and disadvantages, depending on the materials being used and the quality requirement. Types of Materials to Laser MarkMany different types of materials can be laser marked, including:

What Kinds of MarksLaser marking Is used in many industries including automotive, aeronautics, energy, metallurgy, medical, agriculture, agri-food, defense, electronics, railway, lifting and public works, mechanics, motorcycles, heavy trucks and numerous others. Laser marking can be used to create a variety of marks, including:

Types of Laser MarkingThere are several types of laser marking that can be done, including:

What Industries is Laser Marking Most Commonly Used?Laser marking is used in a wide range of industries, including:

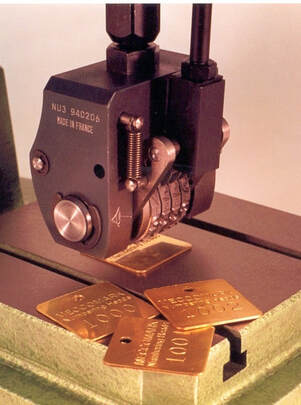

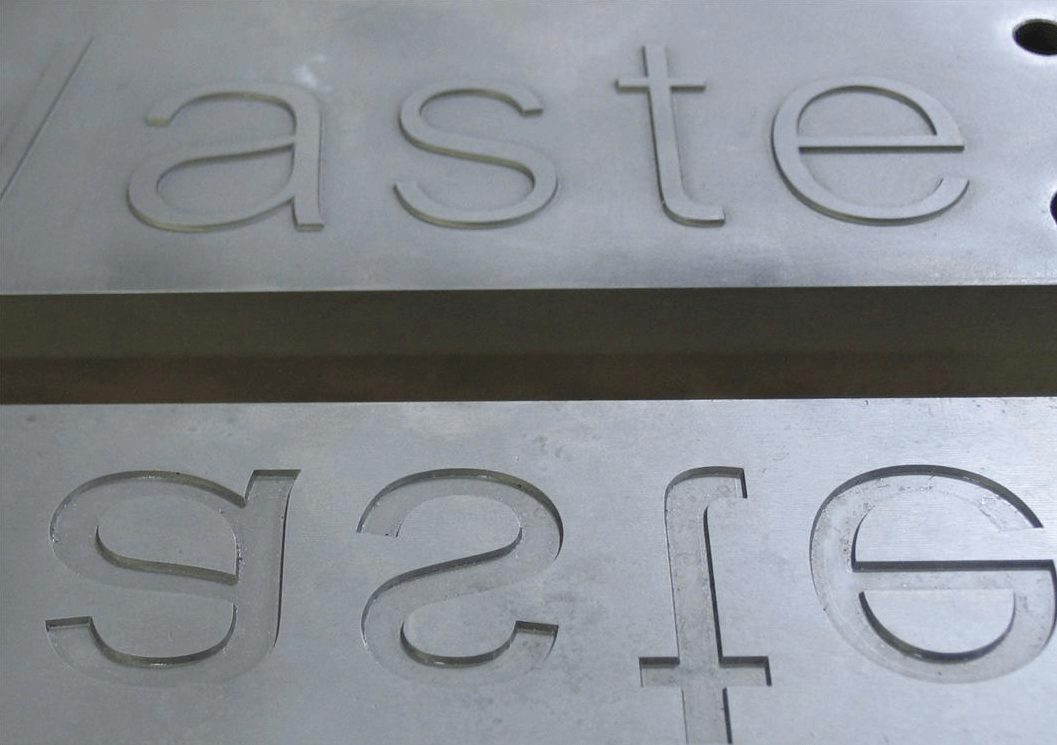

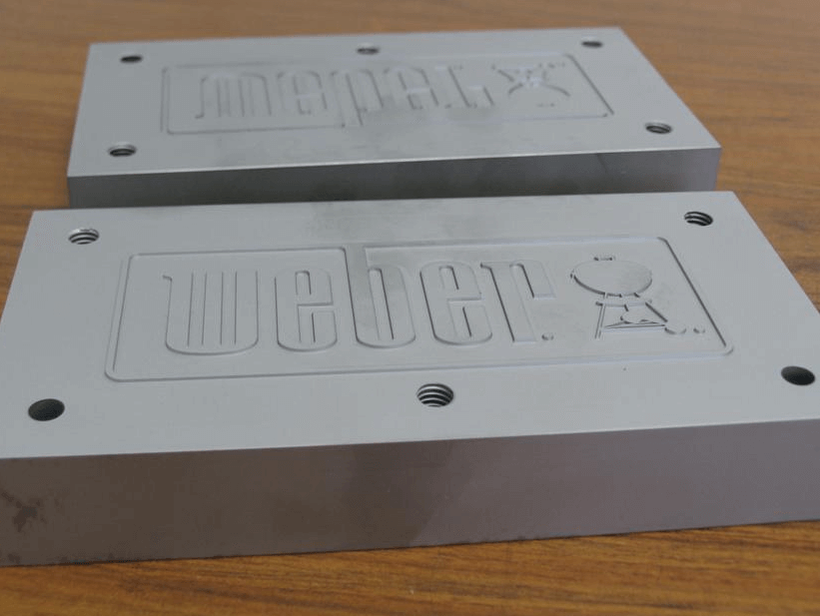

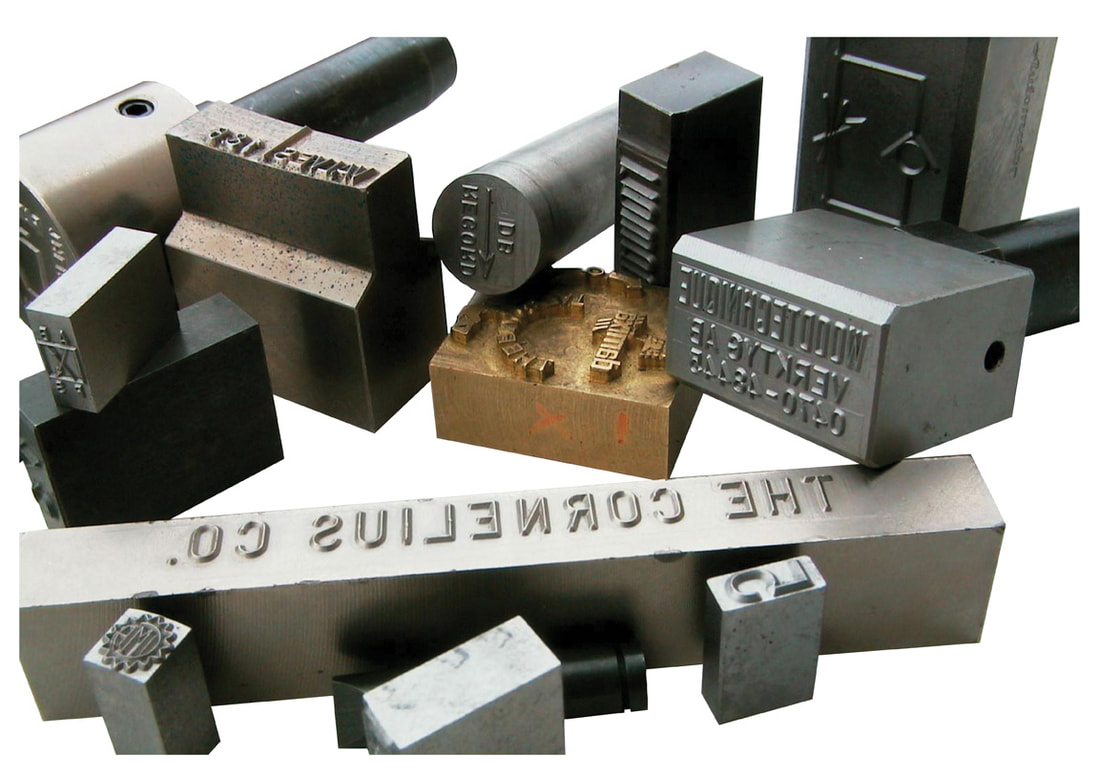

There are lots Steel Stamps and Dies available off-the-shelf to meet many of your everyday needs. But when you need something custom or unique, it's good to know that we can have that made for you too! Here are some things to things you should know about steel stamps and dies. Steel stamps and marking dies are custom engineered for identifying a variety of industrial products. Every die blank is machined to the user's specifications. Custom dies satisfy any user requirement for marking machines, punch presses, press brakes and other machines. Custom stamps can be made for marking on flat, curved, concave or convex surfaces - for stamping part numbers, patent numbers, trade names, trademarks, special lettering or other data. Embossing DiesSteel embossing and coining dies are most often used in the sheet metal industry

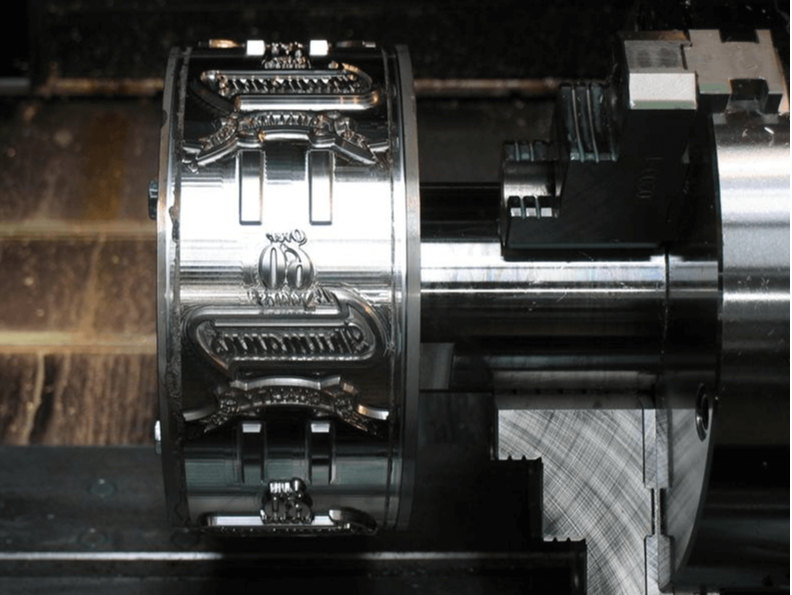

Roll DiesFor marking parts being machined on an engine lathe, turret lathe or screw machine, these rolls can be made for one or more lines of interchangeable type, or with combinations of solid logotypes and individual characters. Steel roll dies offer users a number of advantages. One of the most apparent advantages of steel is life span. Steel is a durable material that offers users a long service life, making steel roll dies a cost effective solution. Steel roll dies also create clear, permanent marks and are strong enough to mark a wide range of materials such as metal, plastic and wood. Custom Steel Stamps, Inserts, Segments and DiesYou can also get custom steel stamps, steel inserts, steel segments, shank stamps and various stamping dies that allow you to direct part mark just about anything. Custom stamps, inserts, and segments can be made for marking on flat, curved, concave or convex surfaces - for stamping part numbers, patent numbers, trade names, trademarks, special lettering or other data. This video shows how Monolith Knives use metal dies and a press to put a makers mark into a knife blank before hardening the blade steel.

In essence, Direct Part Marking (DPM) is applying identification that lasts from cradle to grave and will sustain very rugged environments. Many US government agencies are making unique device identification (UDI) and direct part marking (DPM), mandatory. The private sector, from automotive manufacturers to medical offices have been using DPM more and more as they have embraced the Deming Principles of TQM. Direct Part Marking is used most frequently when marks are needed on a variety metals, plastics and wood. Common equipment solutions range from traditional hand stamping processes to cutting edge technology of fiber laser marking. Direct part marking is often a less costly alternative to purchasing RFID tags. When to Choose Direct Part Marking

Direct Part Marking Options

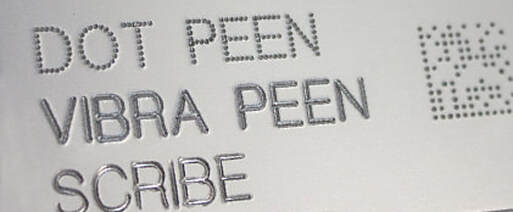

2D Codes: Most Popular for Direct Part Marking In most cases, direct part marking applications use two-dimensional (2D) barcodes such as Datamatrix or QR Code, which carry much more data than linear (1D) barcodes. By using 2D barcodes, manufacturers can also identify very small items and parts.  Dot Peen vs Vibra Peen vs Scribe and a 2D QR code Dot Peen vs Vibra Peen vs Scribe and a 2D QR code 2D codes can pack a large amount of data as opposed to linear codes because they can carry data in two directions on the code vs. just one. To give you an idea of the relative size, a 1D barcode can store around 25 characters up to about 80 characters depending on whether it’s Code 128 or Code 39, but a 2D code can store up to 2,000 characters. In the automotive sector, there is an established standard (AIAG B11) for direct part marking, and a number of large auto OEMs like Ford require suppliers of certain components to use DPM for part traceability. Manufacturers like to use the 2D code not only for the storage capacity, but for their relative size as well (square vs. rectangular). The flexibility of a 2D code allows for the variation in the amount of information stored in the barcode as well as the size of the item being marked. The most popular uses of the mark are for applications that require:

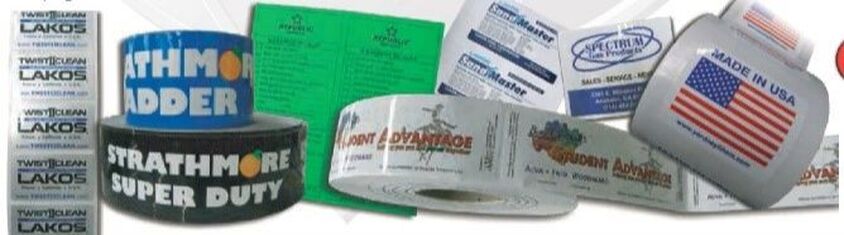

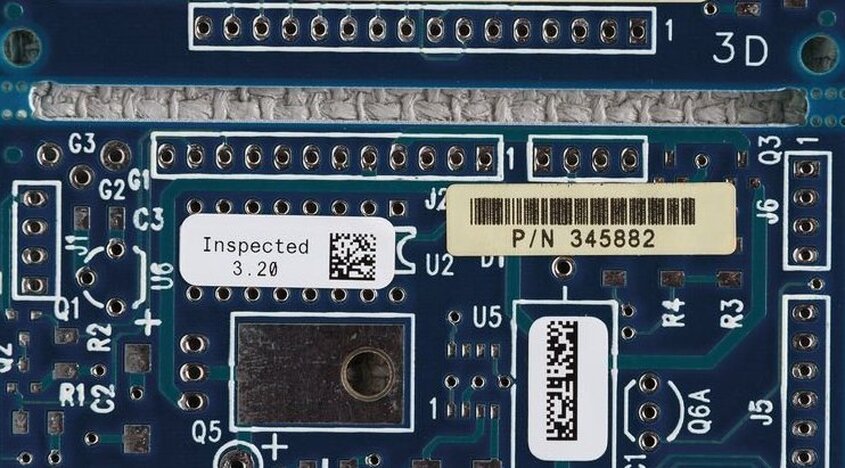

by Laurie Barcaskey Labeling allows identification to be applied and maintains component integrity with no deformation to the surface. Optional adhesives allow the labels to be used in various environments and offer tamper-evident options for security. While there are cost savings in some instances to have labels pre-printed and ready for on-demand application, at other times there is a distinct benefit to printing labels on-demand where label design is done in-house for quick edit corrections or job-specific requirements. Printing In-House In house printing provides flexibility for label details and printing/applying in individual work cells. Volume printing can be maximized through stocking materials for just-in-time printing. If you want to see some of these tools in action, check out the video below. Pre-Printed Labels Pre-printed labels allow you to brand the product with corporate logos and color schemes while heightening the specific product details or cautions associated with their use. About the Author Laurie Barcaskey of Leading Marks is an authorized manufacturer’s representative with 30 years of experience and shop floor knowledge of solutions for industrial identification, part traceability and pipe testing. Laurie is the third generation of one of the marking industry’s most innovative and enduring family legacies, tracing back to 1889. by Laurie Barcaskey There are some rather unique challenges associated with marking different materials. Here's a short overview of things to think about. Metals There are various types of metal marking methods, each of which has its advantages and disadvantages. Three popular types of metal marking include indent, chemical etch, and ink marking. Various methods of marking can be used to mark alpha-numeric, logos or bar codes on metals whether they are bare or painted surfaces – flat or curved surfaces. You can also have an engineered solutions for any kind of mark on any type of metal – from steel pipe to sheet metal to 2D codes, barcodes, large or small character marks, and everything in between. Plastics Plastics require consideration of the chemistry. Hot stamping is most favorable for branding and decorative identification or an application where color contrast is important. Direct indented marks may have challenges for permanence especially if the plastic does not have a memory or if it is too brittle. Labels may not adhere or require very rugged adhesives. Corrosion may be a challenge with inks. Wood Variations in woods offer challenges for marking applications. Hard woods result in better direct-part marks, where soft woods may be too porous for good ink marks. Smooth surfaces yield better results when hot stamping or branding. Rugged adhesives for labeling offer longer sustainability especially when used on shipping containers. Other Materials & Components Precious metals can be marked with impact, dot peen or other non-invasive methods, while concrete is best served with inks, and glass with labels. Circuit boards are commonly marked with labels or chemical-etch processes that are being replaced by laser marking. Specialty equipment may require decal kits for branding, as well as serial plates for warranty identification. Whatever the material substrate to be marked, options are available to suit your requirements and budget. Leading Marks wants to help you identify solutions and improve your processes. About the Author Laurie Barcaskey of Leading Marks is an authorized manufacturer’s representative with 30 years of experience and shop floor knowledge of solutions for industrial identification, part traceability and pipe testing. Laurie is the third generation of one of the marking industry’s most innovative and enduring family legacies, tracing back to 1889. by Laurie Barcaskey Stamps & Stencils, Portable Devices, and In-Line Systems apply marks directly onto product without disturbing the product integrity and eliminates the need to apply labels where adhesive may be a deterrent. Electronic devices provide versatility of changing marking detail quickly and automatically.

Varying ink options provide contrast to the substrate or when needed to define a process designation. Whether your need is in the manufacturing or packaging process, or at the final stage of shipping, current marking devices improve the process where industrial markers and stencils were common tools of the trade.

by Laurie Barcaskey Applied to products or assets for quick reference and note industry compliance. These items are available in plastic, metals, leather, paper and cloth with various retaining options such as adhesive, holes for riveting or screwing, wire strings, or other tamper-resistant mechanisms. Nameplate options include: Imprinted, Blank plates, Asset & Security, and RFID.

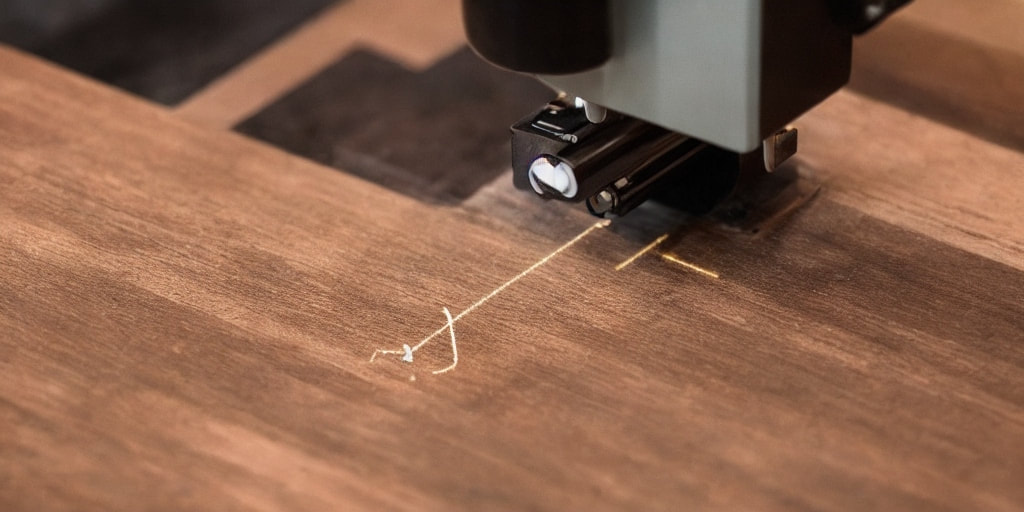

About the AuthorLaurie Barcaskey of Leading Marks is an authorized manufacturer’s representative with 30 years of experience and shop floor knowledge of solutions for industrial identification, part traceability and pipe testing. Laurie is the third generation of one of the marking industry’s most innovative and enduring family legacies, tracing back to 1889. by Laurie Barcaskey Applying identification on to substrates such as plastic, leather and wood for decorative purposes or where other marking methods are not most feasible. Marking methods represented include: Branding Irons, Presses and Marking Dies & Foils.

About the Author Laurie Barcaskey of Leading Marks is an authorized manufacturer’s representative with 30 years of experience and shop floor knowledge of solutions for industrial identification, part traceability and pipe testing. Laurie is the third generation of one of the marking industry’s most innovative and enduring family legacies, tracing back to 1889. |

Follow us on LInkedIN for the latest breaking news!

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it. Archives

May 2024

Categories

All

|

RSS Feed

RSS Feed