|

Laurie Barcaskey, Founder & President of Leading Marks, LLC, spoke to The American Foundry Society Pittsburgh Chapter. on March 4 2021. AFS Pittsburgh is a local chapter of The American Foundry Society based in Schaumburg, Illinois.

Laurie talked about pattern labeling, secondary marking of components, safety signage and labeling shipping identifications and how RFID is improving process control and traceability. T he video is about 15 minutes long and covers technology and where marking is used in foundries.

0 Comments

Check out the full length version of this story “Impacting the Pattern Labeling Process Marking System Increases Efficiency.” at the bottom of the article. A shorter version of this article will also be published by Modern Casting under the title “Marking System Increases Efficiency” in their February 2020 issue. This article presents the story of how the Boss Buddy provides a cost effective, easy-to-use solution to the pattern marking issues that many foundries and manufacturers are facing. It is a case study of Leading Mark’s partnership with Goulds Pumps; the article talks about

As many in the foundry industry know, not only is older marking equipment being phased out; many companies are looking pattern making systems that create more legible and faster labels. Pattern marking is critical since it provides a mechanism for process control and quality Tracking. Tracking piece quality throughout the process allows companies to track operations and limit batch size is issues arise. The Boss Buddy embosses foil tape, is compact, and uses proven components customized to meet foundry requirements. Just a reminder to insure you are prepared for your 2020 marking requirements. The coming year will require extra twos and zeros if you are using individual stamps and type characters for your date codes. Steel marking dies that include the year as part of the marking text need to be ordered NOW to avoid rush charges. Contact us today to get current pricing on your requirements.

Leading Marks handles automated marking systems that allow for date codes to be applied as part of the marking details. If you are looking for budgetary quotes for your 2020 budget, we can help. Traditional Marking tools Leading Marks offers include:

Got question or know what you want contact us today online or by phone: 412-366-4733. by Laurie Barcaskey It’s been an exciting year for manufacturing with the upsurge in orders due to a stronger economy. Many companies are experiencing extraordinary demands for products; at the same time they are challenged to meet delivery schedules. The demands on the industrial sector are made more pressing by the shortage of skilled workers; a situation that doesn’t show much sign of changing soon. We think it is an appropriate time to reflect on the ways Leading Marks is working with to improve both the marking processes on the shop floor and assist in building tomorrow’s workforce for manufacturing. Leading Marks participated in a number of events, but we thought we would highlight the following ones:

Read our 2018 Winter Leading Marks Newsletter to learn more about these events and see information about our highlighted products:

About the AuthorLaurie Barcaskey of Leading Marks is an authorized manufacturer’s representative with 30 years of experience and shop floor knowledge of solutions for industrial identification, part traceability and pipe testing. Laurie is the third generation of one of the marking industry’s most innovative and enduring family legacies, tracing back to 1889.

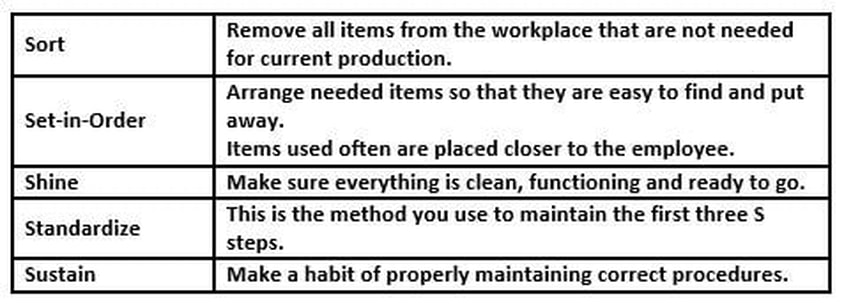

5S is a systematic process of workplace organization. Here's an overview of the five parts. With industry working to be more efficient, due to fewer employees available to complete the work, and using equipment to its fullest potential, manufacturing organizations are seeking to be more intentional about processes that impact the bottom line. Much of this is driven by 5S Good Housekeeping practices. What does this refer to? A short definition is that 5S, or the five pillars of the visual workplace, is a systematic process of workplace organization. A method developed by the Japanese, it works in relationship with lean manufacturing so that organizations can Sort, Set in order, Shine (clean), Standardize and Sustain the process to complete the work in the most efficient manner for just-in-time deliveries. Some manufacturing professionals simply don’t understand the value of the process or don’t see the relevance of the 5S principles. When asked about the components of 5S, these folks might comment, “That’s just a system of keeping things organized and clean, right?” as if it’s some sort of crazy idea about messy toolboxes. Others might react with, “Why make a big program out of cleaning up?” Yet there are focused companies that, once organized, are quick to agree that they witness the benefits of efficiency, experience fewer work-related injuries and have better communication and attitudes among workers. Most importantly, they benefit from cost savings. Successful manufacturers are always seeking ways for continuous improvement that will allow them to provide quality products in a timely manner for the least amount of money. 5S helps drive this through lean manufacturing principles. These organizations take the time to evaluate, collaborate, implement and monitor to make adaptations for the best results. The intent of 5S is to have only what you need available in the workplace, a designated place for everything, a standard way of doing things and the discipline to maintain it. For the operator, the components of 5S create a superior working environment. It gives the operator an opportunity to provide creative input regarding how the workplace should be organized and laid out and how standard work should be completed. Operators will be able to find things easier every time. The workplace will be cleaner and safer. Jobs will be simpler and more satisfying with many obstacles and frustrations removed. First S The first “S” (Sort) requires you to distinguish between what is needed and not needed. Then it requires you to discard what is not needed, which is known as “red-tagging.” A team goes through all items (tools, equipment, material, etc.), and each member asks the question: “Do I need this to do my job on a regular basis?” Items that are used very infrequently or never used should be red-tagged. After determining what is actually needed, all documentation is updated to reflect the necessary parts. Second S The second “S” (Set in Order) requires you to organize things so that they are simple to use and label them so that anyone can find, use and return them to the correct place easily. Where it is practical, visual controls should be used in this activity, such as labeling, signage and a communication device within the work environment that tells you at a glance how work should be done. The requirements for setting in order include:

Third S The third “S” (Shine) involves bringing the workspace back to proper order by the end of each day. It requires periodic cleanup (at least once daily), responsible person(s) identified for cleanup, establishment of cleanup/restocking methods (tools, checklists, etc.) and periodic supervisor inspection. Fourth S The fourth “S” (Standardize) is the method by which you maintain the first three “S” steps. Organization, orderliness and cleanliness are maintained and made habitual by instituting 5S duties into regular work routines. The methods need to be standardized and required company-wide. Fifth S The fifth “S” (Sustain) allows the organization to sustain its 5S program by requiring:

While the initial thought of digging into the entire process may be an overwhelmingly tedious idea for an organization, the benefits of clearing the old, unused equipment of the past provide renewed energy for organizing and improving the future of the total organization. It requires honest assessment of what it takes to be efficient and strong discipline to maintain 5S. In today’s hectic work environments, finding the time to collaborate on this topic is the first challenge. Next comes the budgeting and implementation to make it happen. With dedicated, knowledgeable vendor partners, the task of organizing, identifying and inspecting the process becomes easier. Through creative dialogue with your team, you can find flexible ways to complete the task and encourage continued practice of 5S Good Housekeeping. ABOUT THE AUTHORS:

John Newbold, Business Development Manager, has been with Mobile Epiphany for three years. Over the past 12 months, he has been leading the scope of mobile applications for manufacturing that include 5S Good Housekeeping, Work-in-Process and Environment, Health & Safety Inspection, among others. Contact John at Mobile Epiphany, 416-526-7971, 2675 South Abilene Street, Suite 100, Aurora, CO 80014 Laurie Barcaskey of Leading Marks is an authorized manufacturer’s representative with 30 years of experience and shop floor knowledge of solutions for industrial identification, part traceability and pipe testing. Laurie is the third generation of one of the marking industry’s most innovative and enduring family legacies, tracing back to 1889. Contact Laurie at Leading Marks, 412-366-4733, 736 W. Ingomar Road #707, Ingomar, PA 15127, www.leadingmarks.com from Marking Industry Magazine, 07/2010 Author: Laurie Barcaskey |

Follow us on LInkedIN for the latest breaking news!

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it. Archives

May 2024

Categories

All

|

RSS Feed

RSS Feed