|

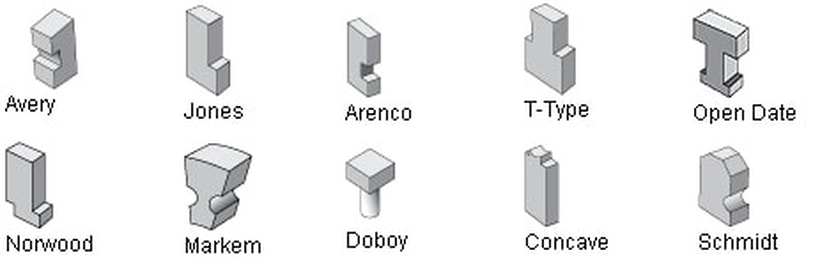

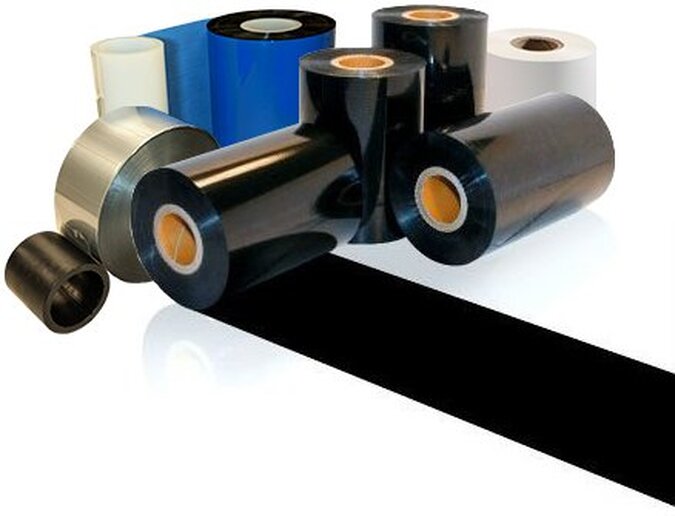

compiled & written by Bernard Martin Whether package marking lot numbers, expiration dates, case codes, 2D barcodes or general package date coding, Leading Marks has the replacement metal coding type and dies, type holders, hot stamping foil, hot melt ink rollers, rubber type, and thermal transfer ribbons needed to be your date coding supply specialist. Leading Marks can supply replacement products for nearly every OEM packaging machine including Markem-Imaje®, Norwood®, Kingsley®, Jones®, Norden®, Open Date®, Rommelag®, Videojet®, Diagraph®, Linx®, Domino®, and many more. Leading Marks can supply you brass and steel dies and Packaging Type used for coding, imprinting, labeling, embossing, and debossing. Our replacement packaging type and steel stamp dies are commonly used in cartoners, sealers, tube fillers, labelers, wrappers, thermoformers, pouchers and baggers (form/fill/seal), and imprinters for hot or cold marking of labels, tags, packages, cartons, boxes, plastic, and/or metal surfaces. Leading Marks carries a broad based package marking product lines to solve the widest variety of packaging marking applications and has the experience needed to make the very best recommendation for your situation. Take a look below at the wide variety of solutions! Metal Type and Logo Dies for Package Date CodingWe can supply brass and steel logo dies and packaging type used for coding, imprinting, labeling, embossing, and debossing. They are the largest manufacturer of replacement metal coding type for all of the popular OEM equipment including Norwood® Imprinters, Markem® Touch Dry Coders, Jones® Cartoners, Open Date® Labelers, Norden® Tube Fillers, Kalix® Tube Fillers, and many more. Thier replacement packaging type and steel stamp dies are commonly used in cartoners, sealers, tube fillers, labelers, wrappers, thermoform and imprinters for hot or cold marking of labels, tags, packages, cartons, tubes, boxes, and plastic. Foils and Ribbons for Date CodingLeading Marks supplies a variety of thermal transfer ribbons for imprinting variable data such as production dates, expiration dates, storage life, bar codes, and more on a wide range of substrates and across many industries including food and beverage, cosmetics, pharmaceuticals, manufacturing and more. Industrial Inkjet Printers for Package Date Coding & Part MarkingLeading Marks offers a variety of ThermalInkjet (TIJ) printers and configurations providing crisp high-resolution codes for both porous and non-porous products. Easy to use, hassle-free and afford able technology that can b e easily installed into both new and existing production lines. We supply inkjet printing systems to meet all of your direct part marking needs whether you need an inline inkjet printer or a portable inkjet printer. Hot Stamping Printers for Date CodingLeading Marks offers a complete line of hot foil stamping printers to meet all of your packaging requirements, including date coding, wire marking and heat shrink sleeving, and even decorative hot stamping for personalization.

0 Comments

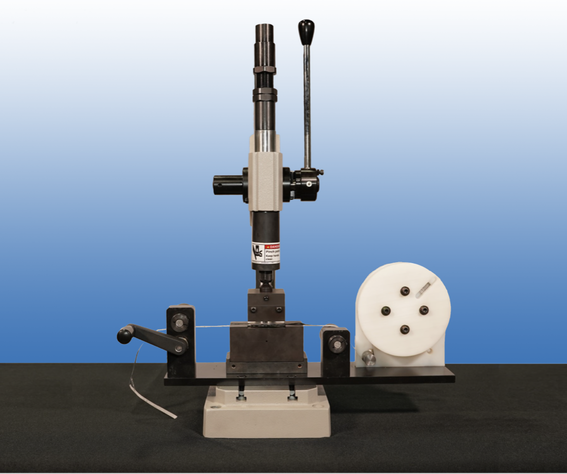

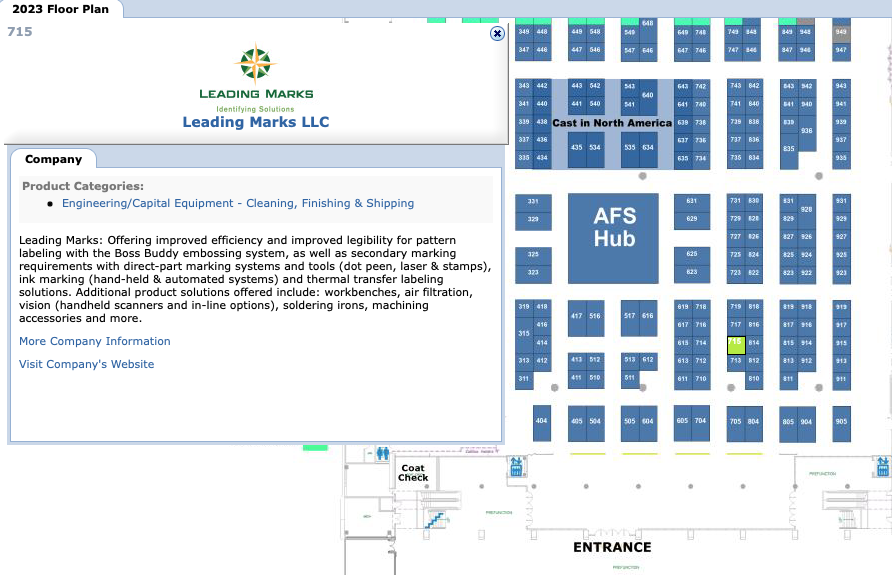

Metalcasting Congress returns to the Huntington Convention Center in Ohio on April 25-27, 2023. Explore the Future of Metalcasting at Leading Marks Booth 715! See the latest trends in smart manufacturing! The newest equipment for your plant! The best in research and expertise. Get a head start on the competition by exploring tomorrow’s metalcasting advancements today. The Metalcasting Congress attracts attendees from across the foundry industry, as well as professionals from other businesses within the manufacturing supply chain. Leading Marks will be previewing improved efficiency and improved legibility for pattern labeling with the Boss Buddy embossing system, as well as secondary marking requirements with direct-part marking systems, dot peen, laser & stamps, ink marking, hand-held & automated systems and thermal transfer labeling solutions. Additional product solutions offered include: workbenches, air filtration, vision, handheld scanners and in-line options, soldering irons, machining accessories and more. Leading Marks will be demonstrating the following products in our booth #715 Boss Buddy The Boss Buddy makes it simple to produce pattern labels. With consistently embossed characters the end-results provide better legibility of heat numbers, date codes and other traceable cast in identification of cast products. EBS 260 Handjet Portable Printer The EBS Handjet product line is designed to deliver the highest performance. They are ideal for printing on porous and non-porous materials. Some of those substrates include foil, glass, metal, lumber, concrete, and various other surfaces. Durable Mecco Stamp Grip Durable Technologies' Safety First Stamp Grip provides improved hand protection and better marks. It provides a safer alternative for operators who prefer to hold stamps in-hand. Pocket sizes range from 1/4" to 1" square. Your hand stamp must be a minimum of 2.5" in length to work in the Safety First Stamp Grip. Visit Leading Marks at Booth 715Stamping presses combine the customization of steel stamps, type, and dies with medium- to high-volume repeatability in an easy-to-use marking machine. Stamping presses, also referred to as impact presses, are either manual or pneumatic marking machines that incorporate a holder filled with steel type, a shank stamp, a roll die, or a numbering head above the marking surface; force is generated by compressing and then releasing a spring inside the press, and then the die is driven down which transfers the image from the face of the die onto the surface being marked. Stamping presses can be integrated into a production line or mounted, like the one in this video, on a bench top. In this video you can see a manual, spring actuated press in action. Why Use a Stamping Press?Stamping presses are an excellent marking solution for repetitive indent marking applications. They are low maintenance machines that are relatively straight forward to use. Manual impact presses, in particular, are easy to operate. One of the most important advantages of a stamping press is that it combines the flexibility and customization of steel stamps, type, dies, and numbering heads with machines that are ideal for medium- to high-volume applications. Stamps, type, and dies can be customized with logos or custom fonts and are manufactured from hardened, high-grade tool steel for long service life and durability. How Do They Work?

Manual Stamping PressesManual impact presses offer users a safe, reliable marking solution that is easy to set up and to operate. This manual style of press is best suited for low- to medium-volume applications. If you're not sure whether you need a manual or pneumatic stamping press, or have any other related questions, please contact us here. Unlike more complicated marking solutions, manual impact presses are low maintenance solutions that are easy to set up and operate. The simplicity of the manual press, coupled with the degree of control it offers, its safety, and reliability, make it a popular marking solution. Specifically, high volume repetitive indent marking applications are best handled with the use of impact presses which achieve a very short cycle time that cannot be met with any other marking method. Pneumatic Stamping PressesIdeal for high-volume applications, pneumatic impact presses can do more than just stamp. Pneumatic impact presses can be used for part marking, riveting, pressing, assembly, stamping, forming, punching, and shearing. This style of press can be operated either manually or with a control package (higher volume applications typically dictate use of a control package). See further below for more information on control packages. When selecting a pneumatic press, there are a few specifications that you should consider to ensure that you are selecting the correct press for your particular marking requirements. Of course, your Durable sales rep can help you with all of the options and features, but in general, the three main areas you will need to consider are the press model, the control package, and the marking dies. Choose Your Pneumatic Stamping Press Model

Choose Your Pneumatic Stamping Press Control Package

Choose Your Stamping Press Marking DiesPneumatic presses can make use of shank stamps, steel type with a holder, or numbering headsfor sequential marking. Your marking requirement will usually dictate which marking dies make the most sense. There is no right or wrong answer when it comes to choosing between a stamp, type, or numbering head. All three are machined from high quality, long lasting steel and can be customized. Numbering heads, however, are designed for serial numbering and sequential part marking, so they are not ideal for all applications Stamping Press ApplicationsThe popularity of the impact press is also due to its versatility. An impact press can be used for a wide variety of applications other than marking including: Stamping presses are typically found in industrial and manufacturing settings, and over the years we have helped a number of companies find the right press for their particular application.

TRC Services Inc. offers a full suite of Sucker Rod Products and Services is designed to help your rod pumping operation work more efficiently in the most cost-effective manner. "We found Leading Marks through a web search as we looked to improve our current dot peen equipment as we implemented the marking of the API monogram to our products." said Stephen Ewing, Quality Manager at Total Rod Concepts (aka TRC Services Inc).

"We would absolutely recommend Laurie Barcaskey of Leading Marks to other companies that have marking and traceability challenges because the customer service before and after the sale and the ongoing technical support is fantastic. The products are top of the line and performance has changed our processing for the better."

|

Follow us on LInkedIN for the latest breaking news!

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it. Archives

May 2024

Categories

All

|

RSS Feed

RSS Feed