|

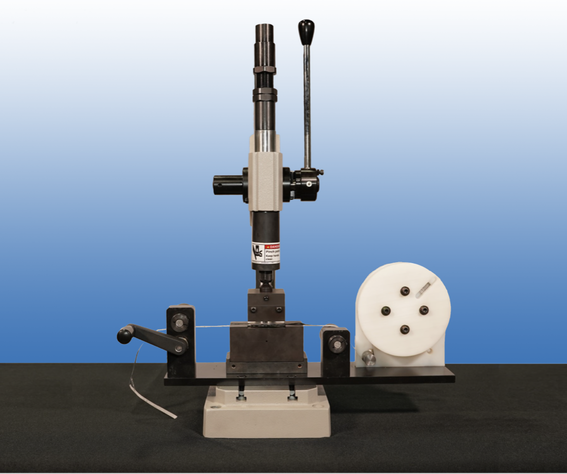

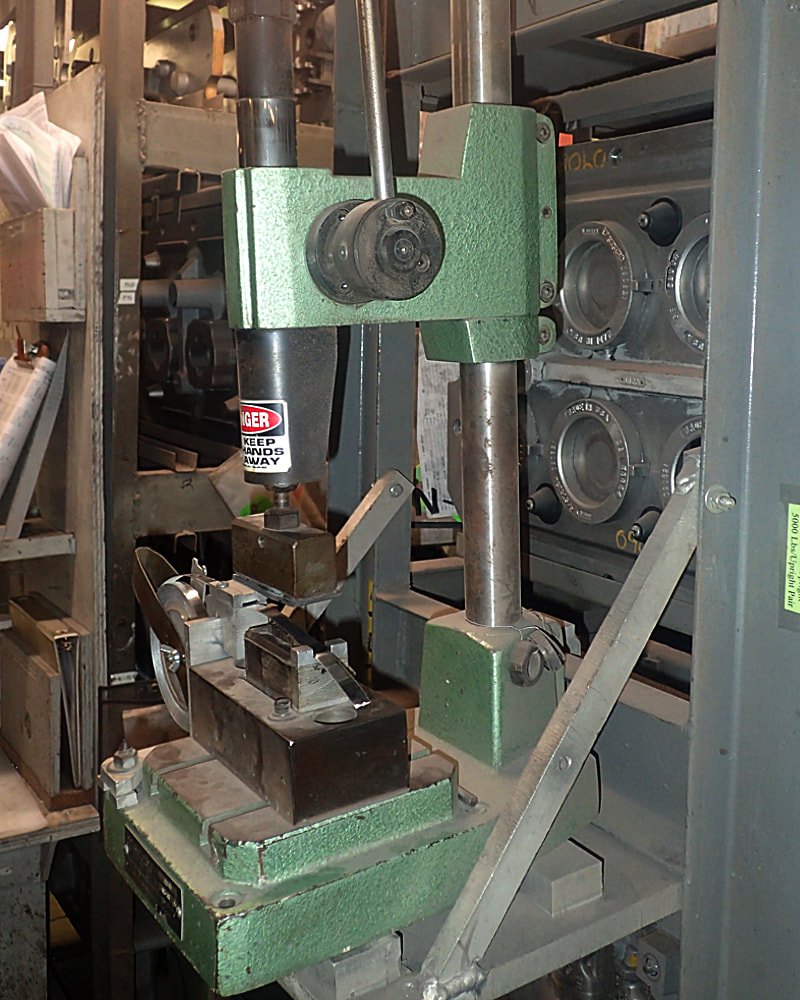

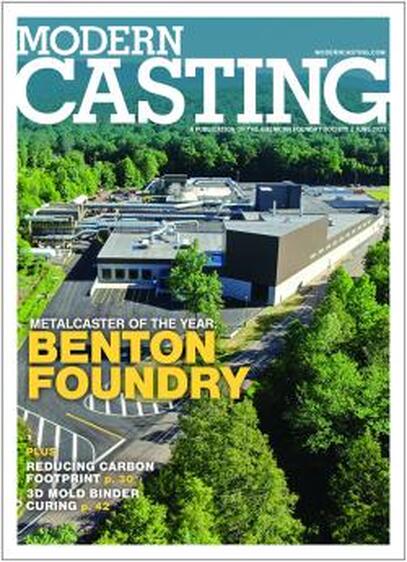

Back in 2002 Benton Foundry presented in the unique problem that needed to be solved. Little did they know that in 2014 Laurie Barcaskey would pull out those very same prints for their custom solution and develop that into the product that is today’s Boss Buddy. For almost a century, the Hall family has been at the forefront of the iron casting industry. Starting in the 1920s with Alfred J. "AJ" Hall, and continuing with his son, Alfred B. "Fritz" Hall, who became president of Benton Foundry in 1975, transforming it from a modest operation pouring 22 tons of iron daily into a visionary enterprise. By 1990, under Fritz's son Jeff, the foundry's capacity increased to 80 tons per day. Benton Foundry has consistently reinvested profits into capital improvements, now operating a state-of-the-art facility with a capacity of 175 tons per day, aiming for 250. Unlike other foundries, Benton has prioritized core room expansion and strategic planning over short-term gains, contributing to its unbroken record of financial growth since 1975. Back in 2002 Laurie Barcaskey at Leading Marks developed the precursor to the today's Boss Buddy as an application solution at Benton Foundary. Traditional embossing, as was being done at Benton, required a male and female die to create the embossed effect on thin gauge materials, often resulting in tearing of the material and inconsistent quality. Fast forward to 2014 and Laurie ran into a similar application problem as the one that she had solved over a decade prior at Benton. And that began the official creation of the Boss Buddy. The inception of the Boss Buddy stemmed from a need to overcome the challenges that Benton had experienced, and dictated introducing a new method that utilizes a female urethane mating piece instead of both dies. This innovative approach not only reduced material waste but also ensured a more consistent quality of embossed characters on metal tapes, such as the foil or stainless tapes available for use with the today's Boss Buddy. Unlike the typical wheel system that embosses one character at a time, today's Boss Buddy employs impact presses that emboss a complete set of characters at once. This method allows for the inclusion of custom characters and longer numbers, offering a solution that is both faster and more consistent. The Boss Buddy's adaptability extends to accommodating different types of metal tapes, catering to a wider range of industry needs. Laurie's expertise in the marking industry played a crucial role in the development of the Boss Buddy, a manual system designed to emboss foil labels used commonly for pattern ID. This system addresses the industry's challenges head-on, providing a solution that leverages traditional components to replace outdated technology. The automation aspect of the Boss Buddy Plus signifies a notable advancement in the foundry sector, where efficiency and reliability are paramount. The continuing story of the Boss Buddy is also one of collaboration and technical support. In the fall of 2023, Jason Karcher of Benton Foundry reached out to Laurie for assistance with the some of the components on the original design solution at their plant that was not functioning optimally. Actually, it's quite a testament to a design that had been in constant service for 20 years. According to Jason Karcher, Tooling Department Manager at Benton Foundry, "There are few options for applying traceability for certified parts so it's essential that this unit remains operational for our process and pattern labeling. The unit was not operating correctly and some band-aids were used until Laurie visited and discussed the replacement parts and shared schematics." Laurie proposed to replace some press parts and introduce new steel type characters, along with arranging for a spare energy section for hot swaps, exemplifies the ongoing commitment to streamlining maintenance allowing a quick return to operation and customer service at Leading Marks. Karcher continues the story. "When the parts arrived, the unit was put back into first-class operation very quickly. It was a simple repair. I spent some time pulling the machine apart. Replaced the items that have worn over the 20-ish years in service. Surprisingly it wasn’t in all that bad shape. The replacement parts fit as expected! The Machine runs well. More importantly I have a greater peace of mind knowing I have replacement parts in house in the event something breaks." "All-in-all the process of ordering, replacing, and stocking the replacement parts/springs & do-dads went very well. I really appreciate Laurie's advice and help on this machine. Her years of knowledge and experience are unmatched. I expect it to run problem free in the back ground for some time." said Karcher. The Boss Buddy's exemplifies how addressing specific challenges through innovation can lead to advancements that benefit the entire sector. Benton Foundry's history, marked by consistent growth and strategic investments, provides the perfect backdrop for the development of such a transformative solution. The Boss Buddy is not just a product; it's a symbol of progress in the foundry industry, showcasing how traditional processes can be reimagined for greater efficiency and reliability. As the foundry sector continues to evolve, the Boss Buddy stands as a prime example of how innovative solutions can drive industry-wide change. Its development process, from conception to implementation, underscores the importance of expertise, collaboration, and a deep understanding of industry challenges. The success of the Boss Buddy and its impact on Benton Foundry's operations highlight the potential for similar innovations to shape the future of manufacturing and industrial processes, ensuring sustainability and growth in an ever-changing technological landscape. METALCASTER OF THE YEAR: BENTON FOUNDRY’S COREMAKING EXPANSIONBenton Foundry, nestled within 200 acres of Pennsylvania's scenic landscape, has been recognized as the "Metalcaster of the Year" by Modern Casting magazine for its significant coremaking expansion. This recent project, completing 70,000 sq. ft. of new and renovated space in fall 2022, has notably enhanced the foundry's capacity, efficiency, and job creation. The expansion reflects Benton's long-standing philosophy of reinvestment and modernization, a practice initiated by Fritz Hall in the 1970s and continued today under the leadership of his son, Jeff Hall, the current president.

The full article provides a detailed account of Benton Foundry's strategic growth, technological advancements, and the positive impact of its recent expansion on the foundry industry and local community. For more insights into Benton Foundry's remarkable journey and its vision for the future, read the original article in Modern Casting magazine.

Read the full article here

0 Comments

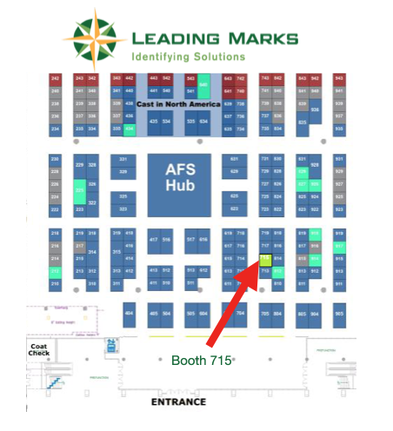

Metalcasting Congress returns to the Huntington Convention Center in Ohio on April 25-27, 2023 – and you can visit Leading Marks in Booth 715! The Metalcasting Congress attracts attendees from across the foundry industry, as well as professionals from other businesses within the manufacturing supply chain. Nestled along Lake Erie’s southern shore, Cleveland is the second largest city in Ohio. Huntington Convention Center of Cleveland is hosting Metalcasting Congress 2023, providing over 410,000 square feet of prime meeting and event space. The convention center is also just 25 minutes away from Cleveland Hopkins International Airport. Leading Marks & Boss Buddy |

| We will also be showcasing secondary marking requirements with direct-part marking systems and tools such as dot peen, laser & stamps, ink marking, hand-held & automated systems, and thermal transfer labeling solutions. We will also be discussing workbenches, air filtration, vision handheld scanners and in-line options, soldering irons, and machining accessories. Huntington Convention Center Cleveland, OH April 25 – 27, 2023 Leading Marks Booth 715 |

Explore the Future of Metalcasting at Leading Marks Booth 715!

Leading Marks will be previewing improved efficiency and improved legibility for pattern labeling with the Boss Buddy embossing system, as well as secondary marking requirements with direct-part marking systems, dot peen, laser & stamps, ink marking, hand-held & automated systems and thermal transfer labeling solutions. Additional product solutions offered include: workbenches, air filtration, vision, handheld scanners and in-line options, soldering irons, machining accessories and more.

Leading Marks will be demonstrating the following products in our booth #715

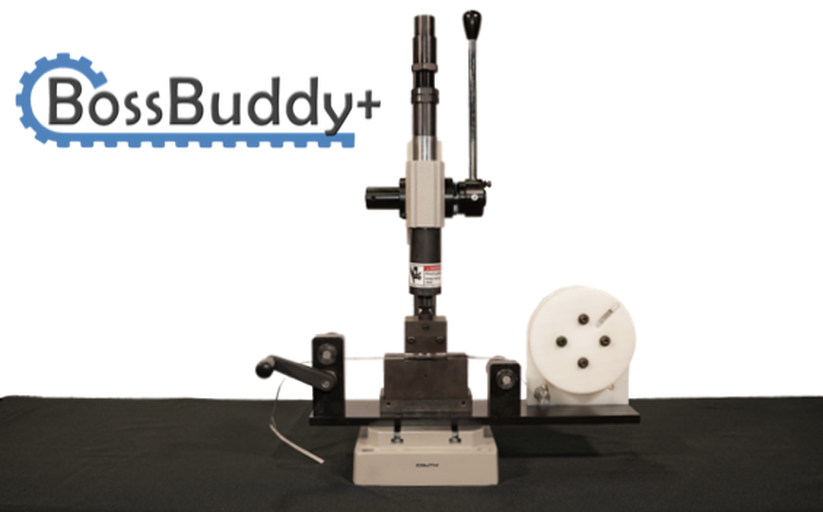

Boss Buddy

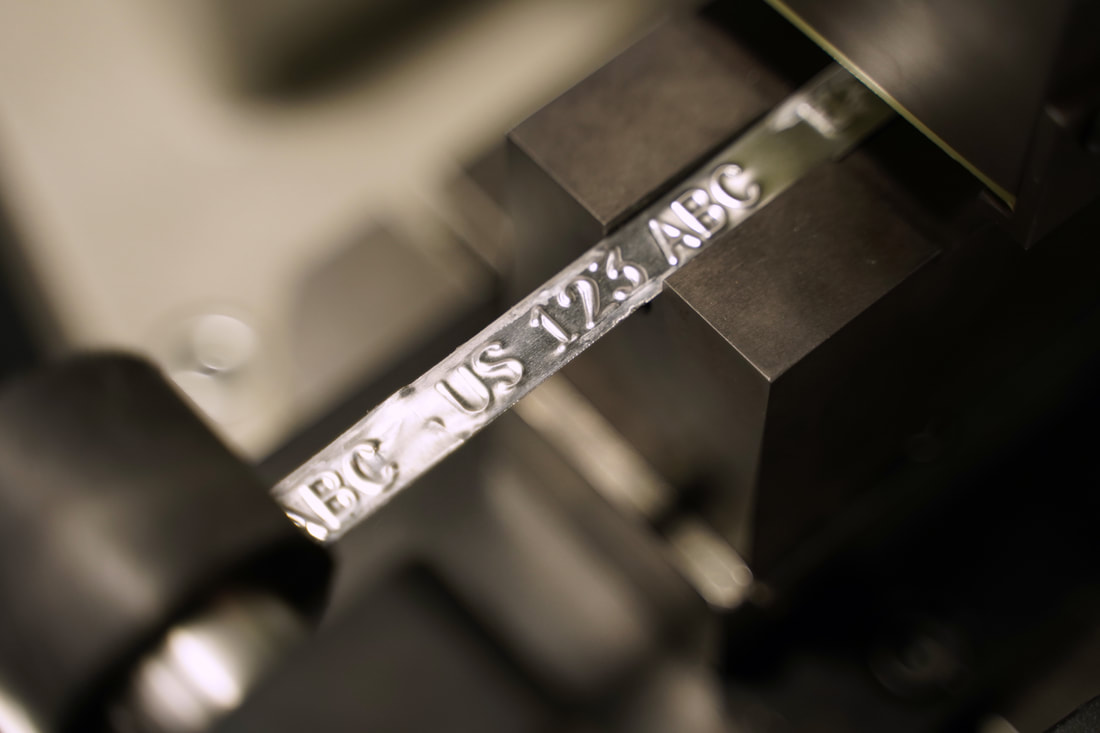

The Boss Buddy makes it simple to produce pattern labels. With consistently embossed characters the end-results provide better legibility of heat numbers, date codes and other traceable cast in identification of cast products.

EBS 260 Handjet Portable Printer

The EBS Handjet product line is designed to deliver the highest performance. They are ideal for printing on porous and non-porous materials. Some of those substrates include foil, glass, metal, lumber, concrete, and various other surfaces.

Durable Mecco Stamp Grip

Durable Technologies' Safety First Stamp Grip provides improved hand protection and better marks. It provides a safer alternative for operators who prefer to hold stamps in-hand. Pocket sizes range from 1/4" to 1" square. Your hand stamp must be a minimum of 2.5" in length to work in the Safety First Stamp Grip.

Visit Leading Marks at Booth 715

In many foundries, the equipment used to apply the date codes, heat numbers and other traceable identification elements applied to patterns is aging badly. The preferred equipment, used for decades, requires operators to rotate a wheel engraved with a given character size, one character at a time.

Rotating the heavy wheel to make multi-character labels is cumbersome and time-consuming. Additional character sizes meant the investment in duplicate systems to meet the various size requirements because the different-sized character sets and base equipment are not interchangeable.

If multiple labels of the same legend are required, the process repeats. Manufacturers requiring high levels

of traceability, such as automotive and aerospace, often have significant investments of time and equipment. These resources are needed to make all the additional labels used to identify line number, operator ID, or other fac- tors so they can minimize batch size if a recall occurs.

The manufacturers that built these systems in the past have reduced available character sizes and don’t make spare parts for some systems. In addition, some marking companies have either shifted their focus to other, newer technologies where market size justifies production/development costs, or simply shut down. Many foundries are forced to hunt for second-hand parts online or use letters and numbers that can be pinned onto patterns. Parts bought online are hard to find and may be a short-lived solution when purchased used. Pinned on characters work but are not cost-effective. Their application and removal is tedious and time consuming, and the characters cannot always be reused. A shrinking workforce, needed for more important production tasks and not content with such menial work, merely compounds the problem.

ITT Goulds Pumps had tagging equipment that embossed one letter at a time, which made producing tags a time-consuming process. Furthermore, if the letter wheel was not stopped at the correct spot, the tag would have to be scrapped.The tagging equipment operated like a labeler where the user must spin the letter wheel to the desired character, press the lever, and then repeat this process for each letter on each tag. Illegible tagging was also a problem.

The manufacturer determined that new equipment was needed to con- tinue and improve the pattern labeling process. Numerous different solutions were tried. One solution was an automated dot peen marker with tag feeding accessories, but the marks were not legible after the tag was cast in due to the dot pattern. Work continued to improve the solution but after the process was fully implemented, the labeling results were still unsatisfactory. The search for a better, more legible solution proceeded.

During this period, Kevin Lucas, pattern shop supervisor at ITT Goulds Pumps, set out to provide a temporary solution by 3D printing the legend plates. He developed a custom font of characters to create more distinguish- able marks. Though legibility was improved, the time to produce the 3D molded legends was not much faster than rotating wheels.

- The ability to mark multiple char- acter sizes.

- Fast creation of repetitive legends.

- Material that was viable for the

process. - Something that fit the budget.

“We had been struggling with tagging legibility issues for years,” he said. “With our 3D printer, I had been adjusting and proving out a font and tag sizes. I printed thousands of tags, over the course of a year.”

Leading Marks had been working with many foundries around the U.S. to improve their processes. After

working with Leading Marks to test date code samples in a couple of character sizes, Lucas said he obtained much more legible marks that were created in less than half the time of the older system and with far greater ease. With favorable results in hand, they began defining what the package should include: Interchangeable type characters in the custom font that Lucas had designed. Characters in a variety of sizes Manual Boss Buddy embossing system (vs. the automated system).

The Boss Buddy system shipped to the facility in Seneca Falls, New York in the spring of 2019. After Lucas’ preliminary use of the Boss Buddy package in the pattern shop, it moved to the shop floor.

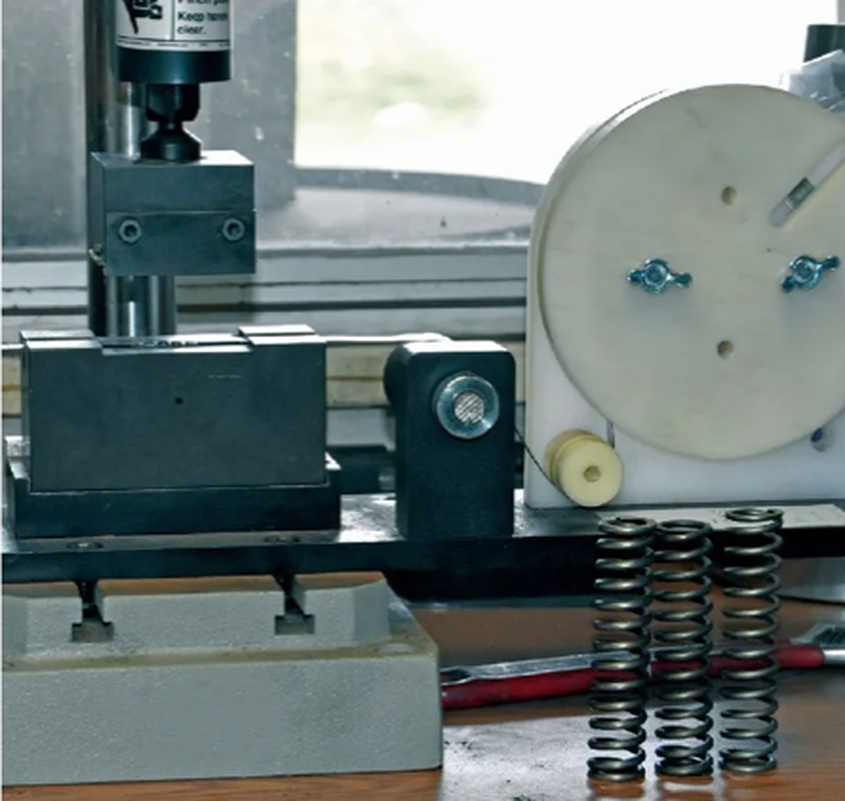

Ryan Knapp, molding supervisor at ITT Goulds Pumps uses it daily, quick- ly creating the pattern labels needed by the foundry. During a follow-up meeting with Laurie Barcaskey from Leading Marks, Knapp created even more clearly defined embossed characters with a simple change in the spring used in the impact press. Knapp is relieved he no longer must use the old system, aka the “Spin to Win” for pattern labels. Knapp will be championing the efforts of other departments to employ this solution throughout the plant.

When asked about the implemen- tation of the new system. Lucas said “I was pleasantly surprised that Leading Marks did not flinch when I men- tioned creating dies for the font I had been 3D printing.”

“Leading Marks had some great ideas on implementing the tagging project. Prior to seeing the Modern Casting piece, I was going in a different direction. It saved a lot of time going with proven equipment and a knowledgeable vendor.”

NEW 2023 Boss Buddy Catalog

Traceability is common for collection, look-up and sharing of data. Whether it is Asset Tracking, EH&S Inspections, QA/QC Controls, Work-in-process, Assembly builds, or Field Service reporting industry is driving the need for traceability from cradle to grave. Why is traceability important for your organization?

What’s the value-add with the potential of data collected through mobile apps or plant-floor software packages?

- Auto-trigger of reports and work orders based on data collected

- Quicker reporting

- Query and filter of data

- Minimize down-time on the production line or field operation

- Trends & variations evaluation

| 2020: a year of less than clear vision presents a challenge to see what the future holds for all of us. This year has left an unforgettable mark in our memories and on our world. With all of the challenges to meet with customers to evaluate applications it has been a good year for Leading Marks. Allow me to indulge you with some details on a few notable installations of marking systems and related manufacturing equipment. |

The Boss Buddy Accessory Package

| The Boss Buddy accessory package continues to be well received for pattern-labeling requirements in the sand cast foundries, and was even featured in Modern Casting magazine for the installation at Goulds Pumps. This package improves the process by eliminating the “Spin-To-Win” rotation of a wheel one character at a time and replacing it with one press stroke embossing multiple characters at one time. Look for a new video of the package in January. |

Direct Part Marking

| With high volume requirements of marking nameplates for regulators, this manufacturer chose to upgrade from an outdated rotary engraver that could engrave approximately 20 nameplates at one time to a Gravotech dot peen marking system equipped with an automatic plate feeder. The unique challenge presented with a variety of curved nameplates is now being well served with faster and more consistent markings. For lower volume requirements they further invested in a custom fixture that mounts on the base of the dot peen and extends over the feeder to accommodate the marking of square, rectangular and round shaped nameplates. |

Ink Marking Solutions

| Whether it was component marking or packaging for the food industry, the Reiner Jetstamp 970 and 1025 handheld ink marking devices solved solutions for several companies. One manufacturer replaced their 2-part epoxy rubber rib stamp process and is now achieving much clearer marks in less time. Another installation at a food processing plant provided a back-up ink marking solution that kept product shipping out the door. Their application stream-lined the process utilizing bar code scanner data entry. |

| The EBS EBS260 Handjet ink device increased in popularity with installations for packaging requirements on poly-mesh bags and replacing stenciling on steel plate — adding to our fabricators and lumber processing facilities already using the equipment. These stand-alone systems are currently applying date codes, shipping details, heat numbers and more in a variety of operations and in different colors! And one of the steel processors capitalized on the process by adding bar code data entry. |

Thermal Transfer Labeling

| The MAX USA Bepop CPM-100HG5 simplified the labeling process for their mold cables and now have wrap-around labels on-demand to fit a variety of cable sizes. The ease of printing and cutting with the details required on the labels per job provides savings in cost and time. The options for different color vinyls and ribbons provides many options for varying products. |

Related Manufacturing Equipment

| The TBH line of air fume and filtration systems has proven to be a great asset for our current laser marking customers. They are no longer spreading undesirable fumes into the general work area and improved their maintenance requirements on the system by eliminating debris in the work chamber. TBH developed a special system design for using systems of the DF series in dental/ medical/ aesthetic fields of application in order to meet the high demand on hygiene and cleanability. Filter and extraction systems protect patients, medical staff and doctors from potentially infectious air, i.e. air contaminated with germs, bacteria/ viruses and particles or aerosols. In order to keep as few system parts as possible from contamination, simple and reliable cleaning/ disinfection as well as a convenient filter change are important. |

Looking Ahead to 2021

We strive to better understand your requirements based on the industry specifications, product and/or substrates to be marked, the environment it is subject to, available budget and other expectations that apply.

To better acquaint you to the product solutions and the limited ability to visit during these continued uncharted times, we are preparing a schedule of webinars with our vendors. If you want to be alerted to the workshops, please email [email protected].

Exciting things are in store in 2021 as Leading Marks continues to Identify Solutions to suit your needs.Happy New Year!

| Most folks do not realize that marking surrounds them just about everywhere: food packaging, appliances, and cars. Marking guides us all day long–consider wayfinding signage on the roadways and in stores. If people still look surprised by the role of marking in their lives, I ask if they know how recalls on food and automobiles are managed. The traceable identification applied to food products and automotive components have date codes, lot numbers and other identifiers elements such as bar codes. These marks help manufacturers identify the range of items impacted by product failure or other criteria for return. |

| How those marks get applied differs based on the component, the substrate it is made of, the environment it will be exposed to, the cycle time required to apply the mark and ultimately a company’s budget available to invest in the equipment or solution. Having been in the industry for almost 40 years and one of the few women in this specialty, I enjoy explaining how I got started. |

| After our family business was sold in 2002, I joined a small industrial distributor in Pittsburgh, Pennsylvania. This company focused on providing solutions to electrical and mechanical contractors specifically for pipe & valve labels and wires & panel identification. This broadened my knowledge of marking to include technologies such as thermal transfer and a variety of ink marking applications. It also introduced me to the construction industry. It is my appreciation for how buildings are constructed, and things are made that piques my interest for providing marking solutions. |

| Knowing my customers and becoming their partner for business needs, includes understanding the challenges they face every day and finding solutions. Leading Marks “Boss Buddy” package was created specifically for the sand-casting industry. This tailored set of accessories allows foundries to upgrade their pattern labeling process as current solutions become obsolete or improve a very cumbersome process. There is also a package that can emboss metal tags that get applied to product post casting or for rugged environments. From my work with customers, I have seen how difficult it is for manufacturing and construction to find and keep qualified technical staff. |

| The focus on college degrees has left all the trades in short supply of skilled staff to produce items we all rely on. Recognizing that I can make a difference, I have chosen to be involved in the SW BotsIQ program. This career-development program is coordinated through the National Tooling & Machining Association. Everyone in the program gains something whether they are a student or working in the field. It is so encouraging to interact with these high school students. |

The mechanical and life skills the students gain is critical to setting them up for success as they look for jobs, attend trade school, or seek degrees. The suppliers and manufacturers who support them gain direct insight to future employees and the local educational systems and networking opportunities with other professionals. It is a win-win for everyone.

Becoming Women Business Enterprise (WBE) certified opens the doors to opportunities with government and large corporations who value diverse suppliers. This certification also enables me to encourage young women involved in the SW Bots program or just starting their careers within manufacturing and construction. While these industries are inviting more women to be a part of their organizations, there are still many more efforts needed to diversify and level the playing field.

Now that you know all of this about me and a bit of the background of Leading Marks, what is the solution we can help you with?

About the Author

A shorter version of this article will also be published by Modern Casting under the title “Marking System Increases Efficiency” in their February 2020 issue.

This article presents the story of how the Boss Buddy provides a cost effective, easy-to-use solution to the pattern marking issues that many foundries and manufacturers are facing. It is a case study of Leading Mark’s partnership with Goulds Pumps; the article talks about

- The state of pattern marking

- Gould’s search for a solution

- the implementation of the Boss Buddy

As many in the foundry industry know, not only is older marking equipment being phased out; many companies are looking pattern making systems that create more legible and faster labels. Pattern marking is critical since it provides a mechanism for process control and quality Tracking. Tracking piece quality throughout the process allows companies to track operations and limit batch size is issues arise. The Boss Buddy embosses foil tape, is compact, and uses proven components customized to meet foundry requirements.

| Fortunately, we can still connect and talk about your marking and traceability requirements for:

By using the latest technologies for applying and tracking information your company will be able to

The Industrial ID solutions Leading Marks offers include direct-part marking, ink marking, thermal labeling. Leading Marks is also the source for information and supplier for Boss Buddy, which is great for pattern labeling, casting marks and tooling IDs. |

A steel type arrangement embosses the characters into foil tape. The male type is mounted in a steel chase, nested on a manual feed assembly. Included in the feed assembly is a spool feed for the material, friction rollers, and a manual knob for advancing the material. Automated systems included more advanced material feed arrangement.

Character sizes range from 1/8” up to 3/4″ high. Standard alphanumeric characters, as well as symbols and logo are available and quoted upon request.

The accessory package is designed to accommodate three standard tape widths; 13/32”, 5/8” and 7/8”. The 5-mil aluminum tape comes with rugged adhesive that is more pliable on curved surfaces than plastic tapes common to the pattern labeling process.

Leading Marks is a proven supplier for marking and traceability requirements. Our product line includes a variety of direct-part marking systems, manual and electronic ink marking devices, thermal transfer label printers, preprinted labels, nameplates and other bar coded devices. A mobile app completes the traceability requirements for industry with data-collection, work-flow engine triggers, and reporting accessory package.

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it.

Archives

May 2024

April 2024

March 2024

February 2024

January 2024

December 2023

November 2023

October 2023

September 2023

August 2023

July 2023

June 2023

May 2023

April 2023

March 2023

February 2023

January 2023

November 2022

October 2022

September 2022

August 2022

July 2022

May 2022

March 2022

December 2021

November 2021

September 2021

August 2021

July 2021

May 2021

March 2021

February 2021

January 2021

December 2020

July 2020

June 2020

May 2020

April 2020

March 2020

February 2020

January 2020

December 2019

November 2019

October 2019

September 2019

August 2019

July 2019

June 2019

April 2019

March 2019

January 2019

December 2018

November 2018

October 2018

September 2018

August 2018

July 2018

June 2018

May 2018

April 2018

March 2018

February 2018

January 2018

December 2017

October 2017

September 2017

July 2017

June 2017

May 2017

April 2017

December 2016

September 2016

August 2016

July 2016

June 2016

May 2016

April 2016

February 2016

January 2016

August 2015

October 2014

July 2010

Categories

All

AFS Medtalcasting Congress

AFS Pittsburgh

Area Tool

Arromark

Automator

Benson Foundry

Bepop

BizMix

Boss Buddy

Bots IQ

Case Study

Cembre

Clamping

Covid

Date Codes

Design 2 Part

Direct Part Marking (DPM)

Dot Peen

Durable Mecco

EBS Ink Jet

Embossing Dies

Flexpak

Foundry Society

Foundry Solutions

Fundamentals

Gravotech

Handjet

Handstamp

Hexacon

HFO Demo Day

Honeywell

Hot Stamping

IMTS

ITT Gould Pumps

JetStamp

Labeling

Laser Marking

Laurie Barcaskey

Leading Marks

LEDLenser

Manufacturing Expo

Marking

Marking Indsutry Magazine

Max USA

Mfg Advanced Expo

MFG Day

Mitee Bite

Modern Casting

Modern Machine Shop

Nameplates

NTMA

OSHA Compliance

Pitt Chem Day

Presentations

Promotions

Reiner

Reiner Jetstamp 1025

Rising Rust Belt

Roll Dies

Scanners

SDS & MSDS

Signage

Stamping Press

Steel Stamps

Supply Chain

Tags

Tapmatic

Tapmatic MH Marking Head

TBH

TBH BF -Series

TBH GL-Series

Tech Article

Technifor

Technomark

Testimonials

Thermal Printing

Traceability

Trade Shows

Unique Device Identification (UDI)

Videos

WBENC - Women’s Business Enterprise National Council

WBE Women’s Business Enterprise

WBE - Women’s Business Enterprise

Workholding

WOSB - Women Owned Small Business

Zuess Marking

RSS Feed

RSS Feed