|

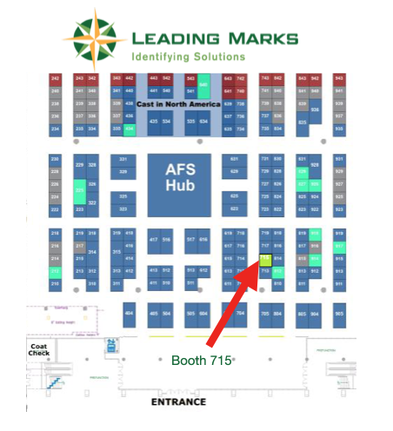

Metalcasting Congress returns to the Huntington Convention Center in Ohio on April 25-27, 2023 – and you can visit Leading Marks in Booth 715! The Metalcasting Congress attracts attendees from across the foundry industry, as well as professionals from other businesses within the manufacturing supply chain. Nestled along Lake Erie’s southern shore, Cleveland is the second largest city in Ohio. Huntington Convention Center of Cleveland is hosting Metalcasting Congress 2023, providing over 410,000 square feet of prime meeting and event space. The convention center is also just 25 minutes away from Cleveland Hopkins International Airport. Leading Marks & Boss Buddy |

| We will also be showcasing secondary marking requirements with direct-part marking systems and tools such as dot peen, laser & stamps, ink marking, hand-held & automated systems, and thermal transfer labeling solutions. We will also be discussing workbenches, air filtration, vision handheld scanners and in-line options, soldering irons, and machining accessories. Huntington Convention Center Cleveland, OH April 25 – 27, 2023 Leading Marks Booth 715 |

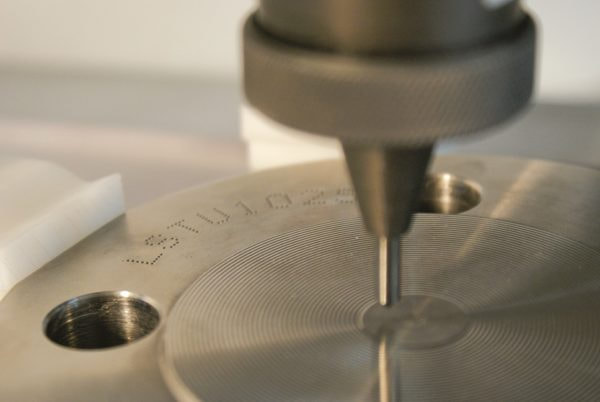

| And while several different types of part-marking exist, Dot Peen marking machines have been a preferred solution for many years. At a high level, Dot Peen marking machines use either electromagnetic or pneumatic force to rapidly oscillate a stylus, in turn indenting the marks onto the surface of the part. One of the advantages of Dot Peen is that it’s very flexible and can be used in either manual or fully automated production lines. A lot of the applications Dot Peen serves are manual applications, however, with modular Dot Peen systems, you can start with a portable system and later convert it to an in-line system for integration with fully automated production lines |

The Basics of Dot Peen Marking

The Dot peen process is considered a “low-stress” marking method because the mark is generated via material displacement rather than material removal. The carbide stylus strikes the material surface to produce the mark via a series of cold-formed stamped dots. Compared to Laser Marking Systems, Dot Peen does not induce thermal shock to the part surface since the material is cold-stamped rather than super-heated to produce the mark.

Dot Peen systems are commonly used by manufacturers in the aerospace and oil & gas industries where low-stress marking is required, such as tubular and flow control products that are exposed to extreme pressure differential in the oilfield.

Dot Peen marking is viable for material hardness up to 63 HRC. Typically, when a part hardness is greater than 63 HRC, laser marking systems are recommended.

All of Technomark’s Dot Peen machines rely on an electromagnetic solenoid to actuate the marking stylus. Dots are plotted in an X/Y plane via electronic control for precise placement of the Dot pattern. Using electromagnetic force versus pneumatic also provides a greater level of control of both the depth of the mark as well as the ability to mark contoured or complex surface.

Dot Peen Marking: Component Traceability In Action

- Automotive

- Oil and Gas (pipes, fittings valves, other)

- Aerospace

- Defense

- Metalworking (general purpose)

| The best Dot Peen marking machines utilize a fully electric design and that doesn’t require compressed air to operate. All Technomark Dot Peen marking machines feature an Intelligent Driving Impact (IDI) function that allows for marking on many different materials and finishes. The IDI function automatically adjusts and levels the stylus to the workpiece. |

When structural integrity is crucial, Dot Peen marking provides a low-stress marking solution that removes no material when marking the part.

Why Choose Dot Peen Marking

- Portability: battery-operated systems are ergonomic and perfect for smaller-scale operations or marking of large, heavy parts that cannot be transported to a fixed location for marking

- Versatility: state-of-the-art Dot Peen marking systems are modular and can start with a portable or manual marking system that can later be adapted to a fully automated production line

- Ease of use: Dot Peen machines are easy to program and do not require any advanced computing knowledge or technical training.

- Permanency: Dot Peen marking process yields a permanent, indelible mark that can withstand harsh operating environments

- Economical: Compared to other marking systems, Dot Peen systems are typically less than $10,000.

- Wireless connectivity between marking head and control (Network-able devices that are able to communicate to other devices through wireless communications)

- On-board diagnostic tools to help the operator know when it’s time for scheduled maintenance — protecting your investment.

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it.

Archives

May 2024

April 2024

March 2024

February 2024

January 2024

December 2023

November 2023

October 2023

September 2023

August 2023

July 2023

June 2023

May 2023

April 2023

March 2023

February 2023

January 2023

November 2022

October 2022

September 2022

August 2022

July 2022

May 2022

March 2022

December 2021

November 2021

September 2021

August 2021

July 2021

May 2021

March 2021

February 2021

January 2021

December 2020

July 2020

June 2020

May 2020

April 2020

March 2020

February 2020

January 2020

December 2019

November 2019

October 2019

September 2019

August 2019

July 2019

June 2019

April 2019

March 2019

January 2019

December 2018

November 2018

October 2018

September 2018

August 2018

July 2018

June 2018

May 2018

April 2018

March 2018

February 2018

January 2018

December 2017

October 2017

September 2017

July 2017

June 2017

May 2017

April 2017

December 2016

September 2016

August 2016

July 2016

June 2016

May 2016

April 2016

February 2016

January 2016

August 2015

October 2014

July 2010

Categories

All

AFS Medtalcasting Congress

AFS Pittsburgh

Area Tool

Arromark

Automator

Benson Foundry

Bepop

BizMix

Boss Buddy

Bots IQ

Case Study

Cembre

Clamping

Covid

Date Codes

Design 2 Part

Direct Part Marking (DPM)

Dot Peen

Durable Mecco

EBS Ink Jet

Embossing Dies

Flexpak

Foundry Society

Foundry Solutions

Fundamentals

Gravotech

Handjet

Handstamp

Hexacon

HFO Demo Day

Honeywell

Hot Stamping

IMTS

ITT Gould Pumps

JetStamp

Labeling

Laser Marking

Laurie Barcaskey

Leading Marks

LEDLenser

Manufacturing Expo

Marking

Marking Indsutry Magazine

Max USA

Mfg Advanced Expo

MFG Day

Mitee Bite

Modern Casting

Modern Machine Shop

Nameplates

NTMA

OSHA Compliance

Pitt Chem Day

Presentations

Promotions

Reiner

Reiner Jetstamp 1025

Rising Rust Belt

Roll Dies

Scanners

SDS & MSDS

Signage

Stamping Press

Steel Stamps

Supply Chain

Tags

Tapmatic

Tapmatic MH Marking Head

TBH

TBH BF -Series

TBH GL-Series

Tech Article

Technifor

Technomark

Testimonials

Thermal Printing

Traceability

Trade Shows

Unique Device Identification (UDI)

Videos

WBENC - Women’s Business Enterprise National Council

WBE Women’s Business Enterprise

WBE - Women’s Business Enterprise

Workholding

WOSB - Women Owned Small Business

Zuess Marking

RSS Feed

RSS Feed