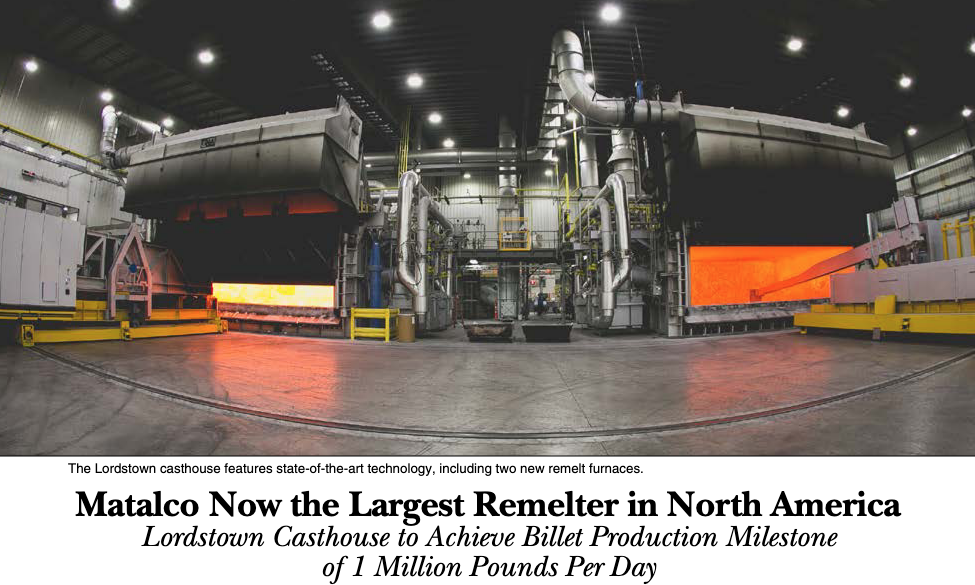

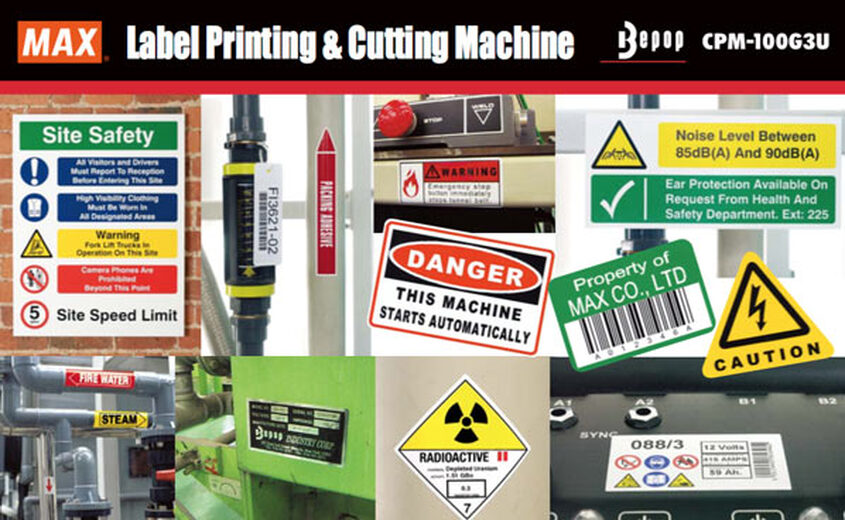

Department of Labor's National Emphasis Program Targets Warehouses and Distribution Centers1/11/2024 Signage plays a crucial role in communicating and mitigating potential hazards written by Bernard Martin In July 2023, the Department of Labor made a significant announcement aimed at fortifying workplace safety across the nation. The unveiling of a new national emphasis program specifically targets warehouses and distribution centers, recognizing the unique challenges and potential hazards inherent in these environments. With a focus on reducing and preventing workplace hazards, this initiative underscores the government's commitment to safeguarding the well-being of employees across diverse industries. From the OSHA News Release: "In the past 10 years, warehousing and distribution centers have experienced tremendous growth with more than 1.9 million people employed in the industry. The Bureau of Labor Statistics data shows injury and illness rates for these establishments are higher than in private industry overall and, in some sectors, more than twice the rate of private industry. "Our enforcement efforts are designed to do one thing: lead to permanent change in workplace safety," said Assistant Secretary for Occupational Safety and Health Doug Parker. "This emphasis program allows OSHA to direct resources to establishments where evidence shows employers must be more intentional in addressing the root causes of worker injuries and align their business practices with the goal to ensure worker health and safety." Under this three-year emphasis program, OSHA will conduct comprehensive safety inspections focused on hazards related to powered industrial vehicle operations, material handling and storage, walking and working surfaces, means of egress and fire protection. The Department of Labor's initiative comes as a proactive response to the evolving landscape of workplace safety. Warehouses and distribution centers, pivotal components of the supply chain, often contend with a multitude of hazards ranging from tripping and fall risks to more complex issues like equipment identification and emergency evacuation procedures. What can you start to do right now to address this three year focus program is a comprehensive evaluation of your signage. Key Area of Focus: |

Follow us on LInkedIN for the latest breaking news!

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it. Archives

May 2024

Categories

All

|

RSS Feed

RSS Feed