|

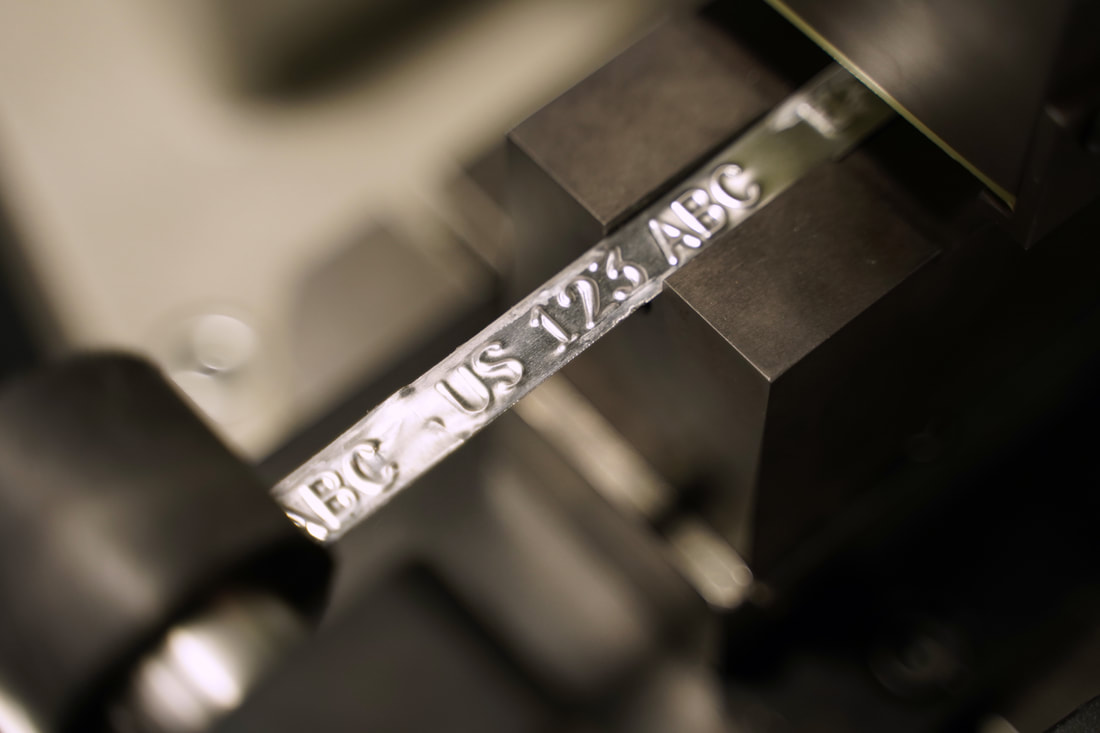

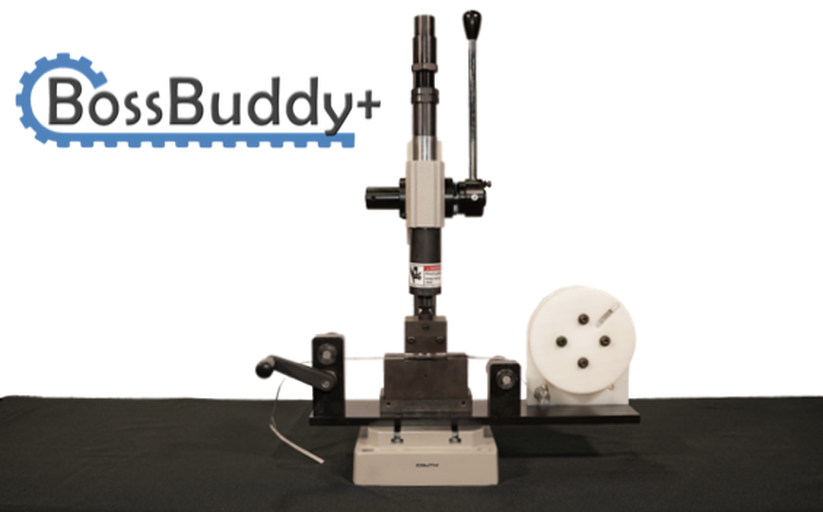

FOR IMMEDIATE RELEASE PITTSBURGH, PA. Leading Marks LLC is excited to announces a package for foundary pattern labeling that improves legibility for cast-in identification, and provides cost savings through labor and material costs. A marking press and a custom designed accessory package impact legends in one stroke of the press rather than rotating wheels one character at a time. The core of the package that hammers in the legends is a spring-loaded impact press. These units are proven marking devices with low-maintenance requirements. While manual systems are most common for replacing traditional pattern labeling devices with single character wheels, semi-automated systems are available for high-volume labeling requirements. A steel type arrangement embosses the characters into foil tape. The male type is mounted in a steel chase, nested on a manual feed assembly. Included in the feed assembly is a spool feed for the material, friction rollers, and a manual knob for advancing the material. Automated systems included more advanced material feed arrangement. Three standard chases accommodate a range of character sizes. Chase assemblies can be interchanged to accommodate a wider range of sizes and tape guide arrangements.

Character sizes range from 1/8” up to 3/4″ high. Standard alphanumeric characters, as well as symbols and logo are available and quoted upon request. The accessory package is designed to accommodate three standard tape widths; 13/32”, 5/8” and 7/8”. The 5-mil aluminum tape comes with rugged adhesive that is more pliable on curved surfaces than plastic tapes common to the pattern labeling process. Leading Marks is a proven supplier for marking and traceability requirements. Our product line includes a variety of direct-part marking systems, manual and electronic ink marking devices, thermal transfer label printers, preprinted labels, nameplates and other bar coded devices. A mobile app completes the traceability requirements for industry with data-collection, work-flow engine triggers, and reporting accessory package.

0 Comments

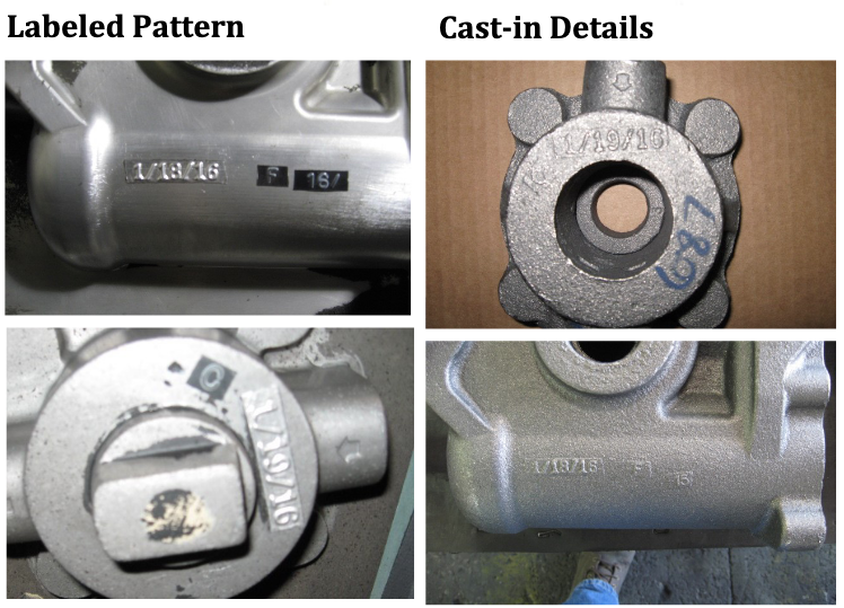

by Laurie Barcaskey The Boss Buddy label system enables better clarity and traceability than cast-in data. Traceability of cast products starts when the patterns are being manufactured. Important data such as date codes, order numbers or other information that needs to survive the life of the casting. Now, you can replace plastic tape material with adhesive-backed foil material with the Boss Buddy! An equipment package for this requirement starts with a pneumatically-operated bench model impact press that has been tooled with marking equipment specific to the customer’s marking requirements. Marking legends manually changed through individual type characters and/or multiple character segment set up. Packages can be operated with dual hand controls, or automated and assembled to include a table and safety precautions. PLC interface allows programming cycle counts. Contact us for more details! About the Author Laurie Barcaskey of Leading Marks is an authorized manufacturer’s representative with 30 years of experience and shop floor knowledge of solutions for industrial identification, part traceability and pipe testing. Laurie is the third generation of one of the marking industry’s most innovative and enduring family legacies, tracing back to 1889. |

Follow us on LInkedIN for the latest breaking news!

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it. Archives

May 2024

Categories

All

|

RSS Feed

RSS Feed