|

Leading Marks is honored to announce the addition of Honeywell scanning solutions to our industrial solutions product mix. Honeywell makes barcode scanning easy! That’s why Honeywell barcode readers are plug and play with industry-leading scan performance, making even the most difficult-to-read barcodes look good. From warehouse supply chains, manufacturing, to hospital patient care, Honeywell barcode scanners are purpose-built for the demands of your business. This includes:

0 Comments

Leading Marks can help you with traceability from the shop floor where machine to machine communication and data-collection is crucial to mobilizing reporting from the warehouse or in the field.

Traceability is common for collection, look-up and sharing of data. Whether it is Asset Tracking, EH&S Inspections, QA/QC Controls, Work-in-process, Assembly builds, or Field Service reporting industry is driving the need for traceability from cradle to grave. Why is traceability important for your organization? What’s the value-add with the potential of data collected through mobile apps or plant-floor software packages?

by Laurie Barcaskey When I started Leading Marks in June of 2014 it was exciting, frightening and everything entrepreneurs prepare for (and some things they don’t!) Over the last three years I have researched and chosen vendors and products that are current with innovative solutions and supportive staff. This includes global names in the marking and traceability arena. Some I’ve known for years and others only more recently.

My interaction with you on these projects allowed me to gain insight to other manufacturing challenges. And I value the lessons I have learned, the information you have shared, and most of all for becoming not only my customer, but my friend. The one lesson I have learned is that “Traceability” is not an isolated need for any one particular industry. Traceability pertains to assets, and assets are defined by the organization, and the process. The asset has attributes that help define and track through the various process to help organizations capitalize on the information captured for delivery updates, insure stock availability, confirm proof of delivery, proof of work, and a multitude of other aspects that minimize an organizations risk. Should you be considering a project with me now, I hope to gain your trust and partner with you to implement the solution. Should you be considering a new marking or traceability project – give me a shot! ABOUT THE AUTHOR:

Laurie Barcaskey of Leading Marks is an authorized manufacturer’s representative with 30 years of experience and shop floor knowledge of solutions for industrial identification, part traceability and pipe testing. Laurie is the third generation of one of the marking industry’s most innovative and enduring family legacies, tracing back to 1889. Join Leading Marks Founder, Laurie Barcaskey and the Pittsburgh Business Times to mix, mingle and network with Pittsburgh business professionals at BizMix at an evening networking reception. This event will be held in the second floor private event space at Roland's Seafood Grill in the Strip District.

Would you like to discuss your current marking projects with Leading Marks? Laurie will he talking about industrial strength solutions for

Your reservation includes:

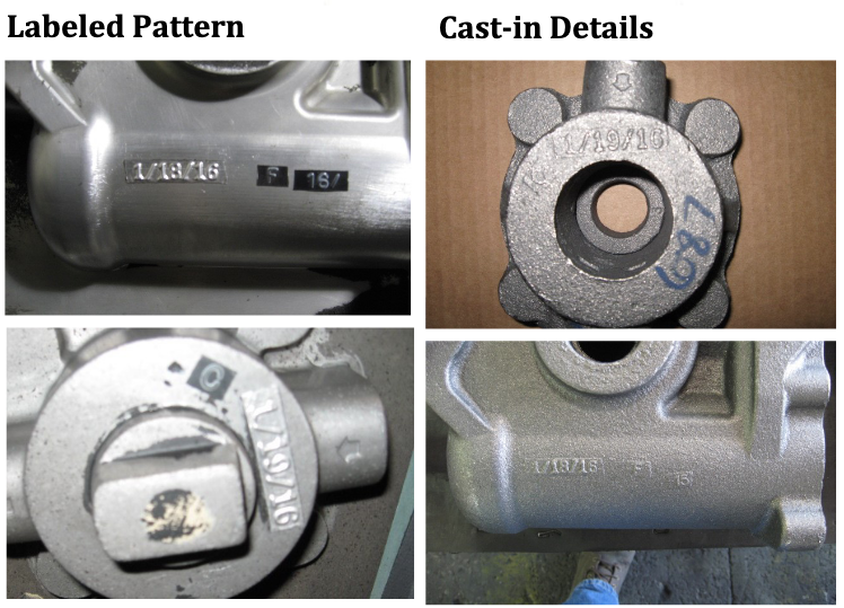

by Laurie Barcaskey The Boss Buddy label system enables better clarity and traceability than cast-in data. Traceability of cast products starts when the patterns are being manufactured. Important data such as date codes, order numbers or other information that needs to survive the life of the casting. Now, you can replace plastic tape material with adhesive-backed foil material with the Boss Buddy! An equipment package for this requirement starts with a pneumatically-operated bench model impact press that has been tooled with marking equipment specific to the customer’s marking requirements. Marking legends manually changed through individual type characters and/or multiple character segment set up. Packages can be operated with dual hand controls, or automated and assembled to include a table and safety precautions. PLC interface allows programming cycle counts. Contact us for more details! About the Author Laurie Barcaskey of Leading Marks is an authorized manufacturer’s representative with 30 years of experience and shop floor knowledge of solutions for industrial identification, part traceability and pipe testing. Laurie is the third generation of one of the marking industry’s most innovative and enduring family legacies, tracing back to 1889. |

Follow us on LInkedIN for the latest breaking news!

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it. Archives

May 2024

Categories

All

|

RSS Feed

RSS Feed