|

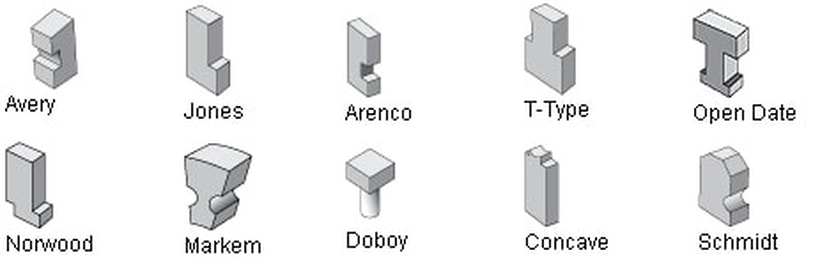

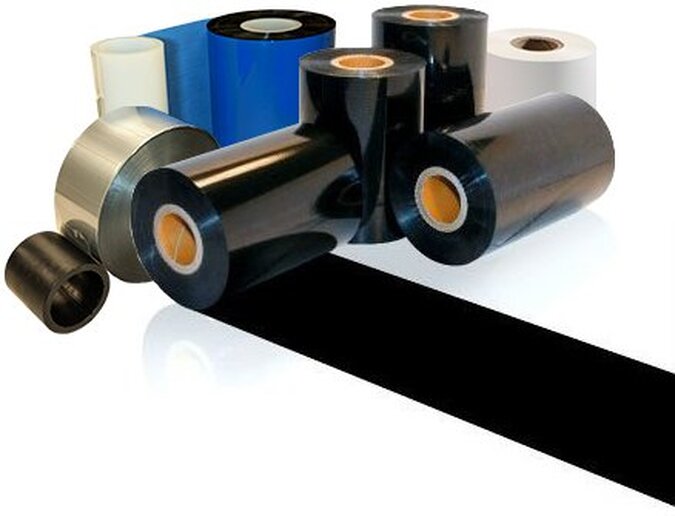

compiled & written by Bernard Martin Whether package marking lot numbers, expiration dates, case codes, 2D barcodes or general package date coding, Leading Marks has the replacement metal coding type and dies, type holders, hot stamping foil, hot melt ink rollers, rubber type, and thermal transfer ribbons needed to be your date coding supply specialist. Leading Marks can supply replacement products for nearly every OEM packaging machine including Markem-Imaje®, Norwood®, Kingsley®, Jones®, Norden®, Open Date®, Rommelag®, Videojet®, Diagraph®, Linx®, Domino®, and many more. Leading Marks can supply you brass and steel dies and Packaging Type used for coding, imprinting, labeling, embossing, and debossing. Our replacement packaging type and steel stamp dies are commonly used in cartoners, sealers, tube fillers, labelers, wrappers, thermoformers, pouchers and baggers (form/fill/seal), and imprinters for hot or cold marking of labels, tags, packages, cartons, boxes, plastic, and/or metal surfaces. Leading Marks carries a broad based package marking product lines to solve the widest variety of packaging marking applications and has the experience needed to make the very best recommendation for your situation. Take a look below at the wide variety of solutions! Metal Type and Logo Dies for Package Date CodingWe can supply brass and steel logo dies and packaging type used for coding, imprinting, labeling, embossing, and debossing. They are the largest manufacturer of replacement metal coding type for all of the popular OEM equipment including Norwood® Imprinters, Markem® Touch Dry Coders, Jones® Cartoners, Open Date® Labelers, Norden® Tube Fillers, Kalix® Tube Fillers, and many more. Thier replacement packaging type and steel stamp dies are commonly used in cartoners, sealers, tube fillers, labelers, wrappers, thermoform and imprinters for hot or cold marking of labels, tags, packages, cartons, tubes, boxes, and plastic. Foils and Ribbons for Date CodingLeading Marks supplies a variety of thermal transfer ribbons for imprinting variable data such as production dates, expiration dates, storage life, bar codes, and more on a wide range of substrates and across many industries including food and beverage, cosmetics, pharmaceuticals, manufacturing and more. Industrial Inkjet Printers for Package Date Coding & Part MarkingLeading Marks offers a variety of ThermalInkjet (TIJ) printers and configurations providing crisp high-resolution codes for both porous and non-porous products. Easy to use, hassle-free and afford able technology that can b e easily installed into both new and existing production lines. We supply inkjet printing systems to meet all of your direct part marking needs whether you need an inline inkjet printer or a portable inkjet printer. Hot Stamping Printers for Date CodingLeading Marks offers a complete line of hot foil stamping printers to meet all of your packaging requirements, including date coding, wire marking and heat shrink sleeving, and even decorative hot stamping for personalization.

0 Comments

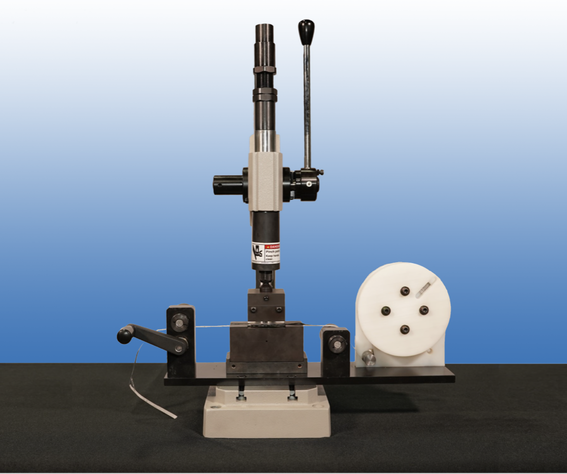

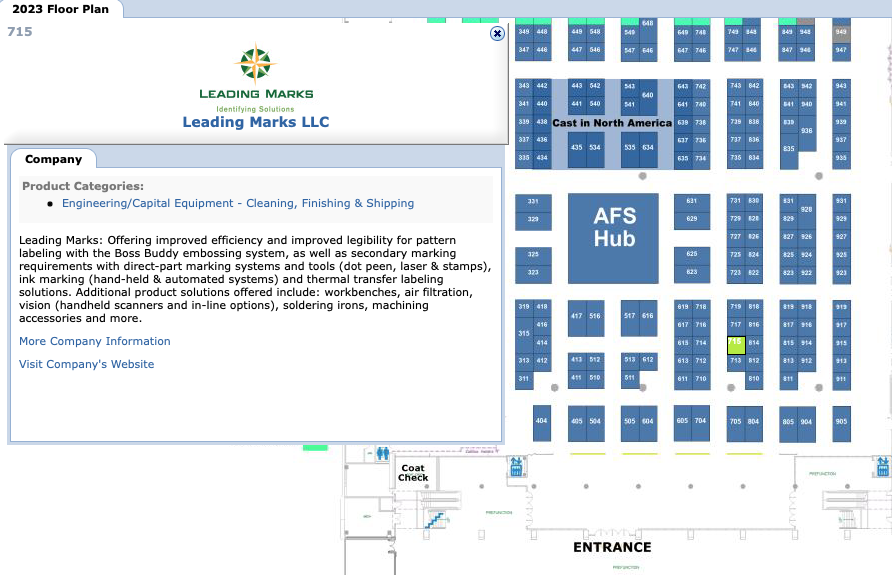

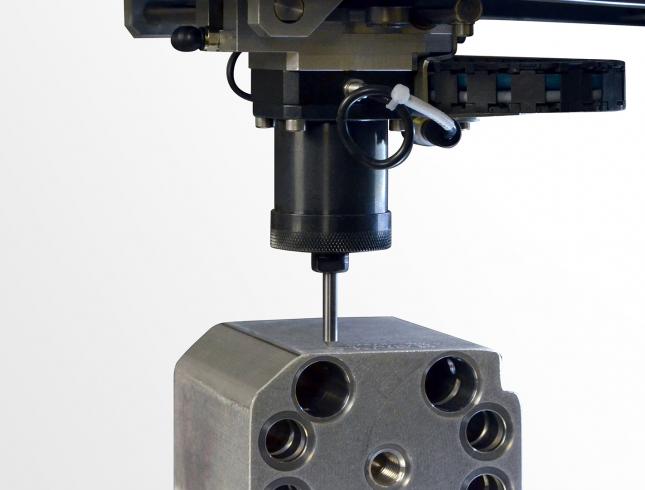

Metalcasting Congress returns to the Huntington Convention Center in Ohio on April 25-27, 2023. Explore the Future of Metalcasting at Leading Marks Booth 715! See the latest trends in smart manufacturing! The newest equipment for your plant! The best in research and expertise. Get a head start on the competition by exploring tomorrow’s metalcasting advancements today. The Metalcasting Congress attracts attendees from across the foundry industry, as well as professionals from other businesses within the manufacturing supply chain. Leading Marks will be previewing improved efficiency and improved legibility for pattern labeling with the Boss Buddy embossing system, as well as secondary marking requirements with direct-part marking systems, dot peen, laser & stamps, ink marking, hand-held & automated systems and thermal transfer labeling solutions. Additional product solutions offered include: workbenches, air filtration, vision, handheld scanners and in-line options, soldering irons, machining accessories and more. Leading Marks will be demonstrating the following products in our booth #715 Boss Buddy The Boss Buddy makes it simple to produce pattern labels. With consistently embossed characters the end-results provide better legibility of heat numbers, date codes and other traceable cast in identification of cast products. EBS 260 Handjet Portable Printer The EBS Handjet product line is designed to deliver the highest performance. They are ideal for printing on porous and non-porous materials. Some of those substrates include foil, glass, metal, lumber, concrete, and various other surfaces. Durable Mecco Stamp Grip Durable Technologies' Safety First Stamp Grip provides improved hand protection and better marks. It provides a safer alternative for operators who prefer to hold stamps in-hand. Pocket sizes range from 1/4" to 1" square. Your hand stamp must be a minimum of 2.5" in length to work in the Safety First Stamp Grip. Visit Leading Marks at Booth 715Marking 5 Lines of Code on Precast Concrete: Oil Crayons Versus EBS-260 Hand-Held Inkjet Printer The HandJet EBS 260 provides reimagined features and functionality for even more innovative, portable coding. The EBS-260’s print height has been doubled to 32 dots with print heights up to 2.2″ and will provide one to four separate lines of code. EBS has increased the capacity of the ink cartridge to up to 200,000 characters in a 7×5 matrix. Single- or multi-line messages from .276″ to 2.2″ high can be printed on both porous and non-porous substrates. It’s ideal for imprinting corrugated, paper, film, foil, glass, metal, lumber, concrete, and many other surfaces. At slightly-over 3.5-lb. the unit features a new redesigned hand grip improved ergonomic grip contours to ensure that handling is comfortable and well- balanced. In the video below, the portable, lightweight EBS-260 marks a 2.2” high pre-programmed text and the printer's built-in laser guidance ensure precise message positioning. The EBS-260 features a touch-screen controller, with a 3.5"-diagonal, hardened screen, enables the user to view the message being printed and make on-the-fly text adjustments. A big thank you to Oldcastle Infrastructure, an industry leader in engineered building solutions, in Elgin, IL. for this video. Leading Marks can help you with traceability from the shop floor where machine to machine communication and data-collection is crucial to mobilizing reporting from the warehouse or in the field.

Traceability is common for collection, look-up and sharing of data. Whether it is Asset Tracking, EH&S Inspections, QA/QC Controls, Work-in-process, Assembly builds, or Field Service reporting industry is driving the need for traceability from cradle to grave. Why is traceability important for your organization? What’s the value-add with the potential of data collected through mobile apps or plant-floor software packages?

The Boss Buddy Accessory Package

Direct Part Marking

Ink Marking Solutions

Thermal Transfer Labeling

Related Manufacturing Equipment

Looking Ahead to 2021 Looking Ahead to 2021 we are excited about the solutions our vendor partners are providing to manufacturing operations, construction projects and food processing requirements. Whether your needs are for marking or the related equipment Leading Marks is prepared to help evaluate your applications with sample marks with the various technologies.

We strive to better understand your requirements based on the industry specifications, product and/or substrates to be marked, the environment it is subject to, available budget and other expectations that apply. To better acquaint you to the product solutions and the limited ability to visit during these continued uncharted times, we are preparing a schedule of webinars with our vendors. If you want to be alerted to the workshops, please email [email protected]. Exciting things are in store in 2021 as Leading Marks continues to Identify Solutions to suit your needs.Happy New Year! Lets meet up at PittChem Day on Tuesday, October 2, 2018. This event, held at Heinz Field, is organized by the Chemical Association of Pittsburgh. The Chemical Association of Pittsburgh is a non-profit corporation formed to foster and promote interest and awareness in the local chemical industry and to encourage wider acquaintance among those engaged in the allied industries. The day long event will feature a number of speakers and some great networking opportunities As a sponsor, Leading Marks will be displaying solutions for marking solutions including:

JADCO Manufacturing, Inc. in Harmony , PA, is a leading global provider of wear resistant steel products to combat impact and abrasion challenges for over 40 years. Founded in August of 1980, JADCO offers an unparalleled array of proprietary products to optimize operations.

by Laurie Barcaskey Stamps & Stencils, Portable Devices, and In-Line Systems apply marks directly onto product without disturbing the product integrity and eliminates the need to apply labels where adhesive may be a deterrent. Electronic devices provide versatility of changing marking detail quickly and automatically.

Varying ink options provide contrast to the substrate or when needed to define a process designation. Whether your need is in the manufacturing or packaging process, or at the final stage of shipping, current marking devices improve the process where industrial markers and stencils were common tools of the trade.

by Laurie Barcaskey Well, we’ve all heard it and hate the saying “but we’ve always done it that way.” Yes, I’m included in saying it, hearing it and resisting the thoughts of change at times but it’s inevitable and best if we embrace it and help make it happen.

Selling marking solutions is no different. I hear reasons like “I’m using Brand XYZ and they have always delivered”, or “it works for our needs right now.” Or even, "Well, it’s interesting but I’m not sure it fits our operation." And of course, "We’ve always done it this way."

Consider hand stamps for direct-part marking. Yes, it might be a caveman way of applying the mark and has its place in production. Let me ask a couple simple questions though.

Well maybe a quick solution is to add a hand stamp holder to make it a safer marking process. Maybe it’s time to consider adding a holder/type arrangement or dot peen marking system that would provide you more consistency not to mention versatility. Then again, maybe it’s using paint markers or stencils & ink rollers to apply text to beams, cartons or preformed concrete components. What a mess and waste of material. Talk about penmanship – what’s it going to be like in the future now that they don’t teach cursive writing in schools? Some of the newest technologies for applying ink marks are handheld, Bluetooth or computer-driven and are more environmentally friendly – not to mention economical in the long run by eliminating material waste or one-time use of stencils.

Well it’s cumbersome to rotate wheels around one character at a time – especially when you might have to make 50 to 100 of the same legend. Using proven, traditional components I’ve been able to take a new solution to an industry that wasn’t even looking. Every mark you make that the customer sees is reflective of your corporate image. Branding is a topic for another day. Yes, you can get inexpensive solutions on the internet, especially for commodity items like labels and rubber stamps. But do you get the service and support that offers alternatives with your company’s interest in mind? Oh I forgot, you’ve always worked with that company and don’t want to make the change. There’s that word again – change. I might not be the one you have worked with for years on your marking solutions. You might not have even been aware that there are experienced consultants out there to help offer suggestions for you to consider. Well there is, and I’m happy to schedule an appointment to review your marking process to see how it might be improved. Identifying solutions and improving processes are what I do. What is it you have been resisting to change? ABOUT THE AUTHOR:

Laurie Barcaskey of Leading Marks is an authorized manufacturer’s representative with 30 years of experience and shop floor knowledge of solutions for industrial identification, part traceability and pipe testing. Laurie is the third generation of one of the marking industry’s most innovative and enduring family legacies, tracing back to 1889. by Laurie Barcaskey When people ask me what I do for a living and I say “I sell industrial identification equipment and solutions for traceability” it’s not unusual to get a blank look and immediately asked “What’s that?” As soon as I mention VIN identification and car recalls they get it and we talk further about the many places that marking is around us.

Now that more and more parts are marked with the addition of bar codes, organizations often struggle with how to capture and use the data. Smart devices and bar code scanners that interface with databases allow quicker capture of the data.

As industry requires marking more often, I must admit that marking and traceability of products has never been more exciting. How can I help you mark your part and capture the details? ABOUT THE AUTHOR:

Laurie Barcaskey of Leading Marks is an authorized manufacturer’s representative with 30 years of experience and shop floor knowledge of solutions for industrial identification, part traceability and pipe testing. Laurie is the third generation of one of the marking industry’s most innovative and enduring family legacies, tracing back to 1889. |

Follow us on LInkedIN for the latest breaking news!

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it. Archives

May 2024

Categories

All

|

RSS Feed

RSS Feed