|

Machines that Make the Signs for the Times Whether it is the elegant requirements of architectural signs, meeting ADA (Americans with Disabilities ACT) wayfinding requirements, or durable safety signs that survive rugged environments how you make the sign matters. Leading Marks is an authorized distributor of the GravoTech engraving systems and the MAX USA Bepop 4-color thermal printers. Specializing in identification requirements, Leading Marks believes in presenting options that allow the customer options to meet the expectations of the job and work within the available budget for the capital investment. Engraving MachinesGravoTech, a leader of direct part marking machinery, offers a complete line of rotary and laser engraving machines. The rotary systems come in compact units for simple tasks of creating small legend plates, switch plates and more.

Thermal PrintersSafety signage and labeling is a critical part of the safety process for manufacturing and construction alike — especially for specialty contractors such as electrical and mechanical. ANSI and OSHA requirements give guidelines to help identify areas where danger or caution should be exercised during operation and/or maintenance of equipment.

The 4-color MAX USA Bepop printers are available in two sizes: 4” and 8”. An investment in either machine allows you to make signs on-demand. They even allow you to cut to size. Signs to GoIf you are not sure investing in capital equipment for your label and sign needs makes sense, Leading Marks also provides stocked and made-to-order solutions too. When these needs arise, it is always helpful to understand your needs. It is also helpful to know the environment for which the label and sign will be used, and the driving need for it. With this information we can recommend the applicable material the sign should be made of meeting ANSI and OSHA requirements. Artwork in digital format expedites the ability to respond quickly. Common standard and customized signs are available for biohazard and hazardous materials, safety, first aid, lockout tagout, machine operation and personal protection. Even rugged applications for aerial, pipelines, substations, traffic signals and other rugged industrial or construction site requirements.

0 Comments

Department of Labor's National Emphasis Program Targets Warehouses and Distribution Centers1/11/2024 Signage plays a crucial role in communicating and mitigating potential hazards written by Bernard Martin In July 2023, the Department of Labor made a significant announcement aimed at fortifying workplace safety across the nation. The unveiling of a new national emphasis program specifically targets warehouses and distribution centers, recognizing the unique challenges and potential hazards inherent in these environments. With a focus on reducing and preventing workplace hazards, this initiative underscores the government's commitment to safeguarding the well-being of employees across diverse industries. From the OSHA News Release: "In the past 10 years, warehousing and distribution centers have experienced tremendous growth with more than 1.9 million people employed in the industry. The Bureau of Labor Statistics data shows injury and illness rates for these establishments are higher than in private industry overall and, in some sectors, more than twice the rate of private industry. "Our enforcement efforts are designed to do one thing: lead to permanent change in workplace safety," said Assistant Secretary for Occupational Safety and Health Doug Parker. "This emphasis program allows OSHA to direct resources to establishments where evidence shows employers must be more intentional in addressing the root causes of worker injuries and align their business practices with the goal to ensure worker health and safety." Under this three-year emphasis program, OSHA will conduct comprehensive safety inspections focused on hazards related to powered industrial vehicle operations, material handling and storage, walking and working surfaces, means of egress and fire protection. The Department of Labor's initiative comes as a proactive response to the evolving landscape of workplace safety. Warehouses and distribution centers, pivotal components of the supply chain, often contend with a multitude of hazards ranging from tripping and fall risks to more complex issues like equipment identification and emergency evacuation procedures. What can you start to do right now to address this three year focus program is a comprehensive evaluation of your signage. Key Area of Focus: |

| TUESDAY MAY 3 Manufacturing Advanced Expo Red Fern 421 Old Kersey Road St. Marys, PA 15846 10:00 am - 3:00 pm | THURSDAY MAY 5 Manufacturing Advanced Expo Ambassador Center Hemingway Ballroom 7794 Peach Street Erie , PA 16509 10:00 am - 3:00 pm |

Traceability is common for collection, look-up and sharing of data. Whether it is Asset Tracking, EH&S Inspections, QA/QC Controls, Work-in-process, Assembly builds, or Field Service reporting industry is driving the need for traceability from cradle to grave. Why is traceability important for your organization?

What’s the value-add with the potential of data collected through mobile apps or plant-floor software packages?

- Auto-trigger of reports and work orders based on data collected

- Quicker reporting

- Query and filter of data

- Minimize down-time on the production line or field operation

- Trends & variations evaluation

About the Letawin Thermal Printer

| The Letatwin printer is a compact printer designed on-demand printing of tubing, tape, and wires. The Letatwin printer has an enhanced feeding system that provides you with a marking speed of 1-1/2” (40mm) per second. It is developed for maximizing productivity of wire and tube marking jobs. This compact package includes the Letatwin printer with an integral keyboard and PC Editor software for connected design of labels. Data can be transferred to a USB flash drive for printing away from the PC. It easily accepts data from Windows Excel or a .csv file reducing the time for data entry. Consumables include heat shrink vinyl tubing and polyester tape. The heat shrink vinyl tubing is suited for 1.5 diameter to 8.0 mm diameter tubes and wires. The tubing is available for flat or round requirements and can be half-cut for ease of applying. The polyester tapes come in a variety of colors in widths from 5mm to 12mm. |

Unique features include the ability to make half-cut or full cut parts, a warming element and optional battery power capability. The enhanced MAX software LETATWIN PC Editor and driver can be downloaded from the MAX USA website.

Connect to a computer and print directly to the machine, or save marker data to the machine's large internal memory and take it with you on-site. Engineered for high productivity and robust environments, including a shock resistant rubber keyboard, you will use your LETATWIN trouble free for many years to come.

The user-friendly software allows you to design labels for your needs or utilize standard templates pre-stored in the library. A complete library of standard icons are also included with the software. The Bepop printers come in two model sizes; one for 4” wide materials and one for 8” materials.

| APPLICATIONS

MAX has been recognized worldwide as a leader of industrial tools and office products. The MAX thermal printers can be found in manufacturing facilities, chemical plants, educational & health care facilities and many more. Thermal printing solutions include the Letatwin and Bepop printers. |

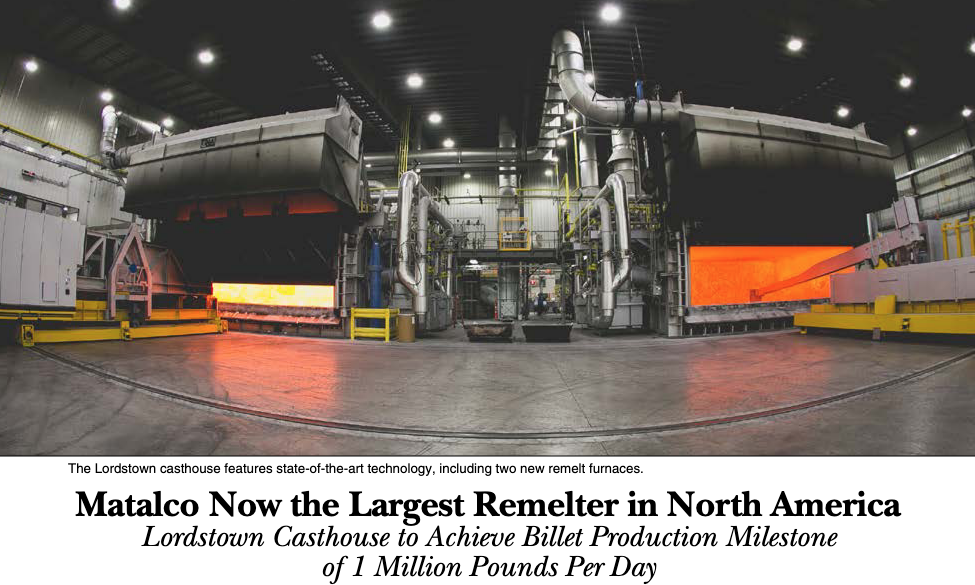

At their Canton, Ohio, facility, Matalco makes new products and aluminum billets from recycled materials. They are using the Bepop printer to make safety-related labels and PPE diagrams.

In addition, Matalco is making labels for things around the plant to improve visual literacy such as daily production information, safety metrics, and labels for hard hats to show certification information. They plan on expanding their use of the tool to label storage locations to make sure things are put away and improve efficiency.

Before they purchased the MaxUSA Bepop printer, Matalco would have to call a graphics designer, create a PO, have it printed elsewhere, and pick the labels up. According to Emily Seibert, the Environmental Health and Safety Specialist at the Canton facility, “Today if we have an idea, boom, we can do it today. We don’t have to wait a week…we can do it right here.”

Emily stated that the system was pretty easy to use and user-friendly from the start, particularly f you are familiar with Microsoft tools like Powerpoint and Paint.

The information for this testimonial from Leading Mark’s customer came from the video shown below. Watch it to learn more about Matalco’s experience with the MaxUSA Bepop CPM-100HG5 label printer.

| 2020: a year of less than clear vision presents a challenge to see what the future holds for all of us. This year has left an unforgettable mark in our memories and on our world. With all of the challenges to meet with customers to evaluate applications it has been a good year for Leading Marks. Allow me to indulge you with some details on a few notable installations of marking systems and related manufacturing equipment. |

The Boss Buddy Accessory Package

| The Boss Buddy accessory package continues to be well received for pattern-labeling requirements in the sand cast foundries, and was even featured in Modern Casting magazine for the installation at Goulds Pumps. This package improves the process by eliminating the “Spin-To-Win” rotation of a wheel one character at a time and replacing it with one press stroke embossing multiple characters at one time. Look for a new video of the package in January. |

Direct Part Marking

| With high volume requirements of marking nameplates for regulators, this manufacturer chose to upgrade from an outdated rotary engraver that could engrave approximately 20 nameplates at one time to a Gravotech dot peen marking system equipped with an automatic plate feeder. The unique challenge presented with a variety of curved nameplates is now being well served with faster and more consistent markings. For lower volume requirements they further invested in a custom fixture that mounts on the base of the dot peen and extends over the feeder to accommodate the marking of square, rectangular and round shaped nameplates. |

Ink Marking Solutions

| Whether it was component marking or packaging for the food industry, the Reiner Jetstamp 970 and 1025 handheld ink marking devices solved solutions for several companies. One manufacturer replaced their 2-part epoxy rubber rib stamp process and is now achieving much clearer marks in less time. Another installation at a food processing plant provided a back-up ink marking solution that kept product shipping out the door. Their application stream-lined the process utilizing bar code scanner data entry. |

| The EBS EBS260 Handjet ink device increased in popularity with installations for packaging requirements on poly-mesh bags and replacing stenciling on steel plate — adding to our fabricators and lumber processing facilities already using the equipment. These stand-alone systems are currently applying date codes, shipping details, heat numbers and more in a variety of operations and in different colors! And one of the steel processors capitalized on the process by adding bar code data entry. |

Thermal Transfer Labeling

| The MAX USA Bepop CPM-100HG5 simplified the labeling process for their mold cables and now have wrap-around labels on-demand to fit a variety of cable sizes. The ease of printing and cutting with the details required on the labels per job provides savings in cost and time. The options for different color vinyls and ribbons provides many options for varying products. |

Related Manufacturing Equipment

| The TBH line of air fume and filtration systems has proven to be a great asset for our current laser marking customers. They are no longer spreading undesirable fumes into the general work area and improved their maintenance requirements on the system by eliminating debris in the work chamber. TBH developed a special system design for using systems of the DF series in dental/ medical/ aesthetic fields of application in order to meet the high demand on hygiene and cleanability. Filter and extraction systems protect patients, medical staff and doctors from potentially infectious air, i.e. air contaminated with germs, bacteria/ viruses and particles or aerosols. In order to keep as few system parts as possible from contamination, simple and reliable cleaning/ disinfection as well as a convenient filter change are important. |

Looking Ahead to 2021

We strive to better understand your requirements based on the industry specifications, product and/or substrates to be marked, the environment it is subject to, available budget and other expectations that apply.

To better acquaint you to the product solutions and the limited ability to visit during these continued uncharted times, we are preparing a schedule of webinars with our vendors. If you want to be alerted to the workshops, please email [email protected].

Exciting things are in store in 2021 as Leading Marks continues to Identify Solutions to suit your needs.Happy New Year!

- Act now to and save $1000.00 on the CPM-100HG5.

- This promotion runs from now until the end of June 2020.

This MAX USA Bepop label printer gives you the freedom to create your own custom signs and labels as needed. Prepare for your re-opening during Covid-19 and solve your labeling and signage requirements with handy solution. No waiting for shipping and no minimum order requirements; print what your want, when you need it. This package includes:

- CPM-100HG5 label printer

- 2 rolls of tape

- 2 ribbons

- an internal cutting system to cut the labels to size

- software to make it easy to edit labels

Call her at 412-366-4733.

Download the Promo Flyer below the video.

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it.

Archives

May 2024

April 2024

March 2024

February 2024

January 2024

December 2023

November 2023

October 2023

September 2023

August 2023

July 2023

June 2023

May 2023

April 2023

March 2023

February 2023

January 2023

November 2022

October 2022

September 2022

August 2022

July 2022

May 2022

March 2022

December 2021

November 2021

September 2021

August 2021

July 2021

May 2021

March 2021

February 2021

January 2021

December 2020

July 2020

June 2020

May 2020

April 2020

March 2020

February 2020

January 2020

December 2019

November 2019

October 2019

September 2019

August 2019

July 2019

June 2019

April 2019

March 2019

January 2019

December 2018

November 2018

October 2018

September 2018

August 2018

July 2018

June 2018

May 2018

April 2018

March 2018

February 2018

January 2018

December 2017

October 2017

September 2017

July 2017

June 2017

May 2017

April 2017

December 2016

September 2016

August 2016

July 2016

June 2016

May 2016

April 2016

February 2016

January 2016

August 2015

October 2014

July 2010

Categories

All

AFS Medtalcasting Congress

AFS Pittsburgh

Area Tool

Arromark

Automator

Benson Foundry

Bepop

BizMix

Boss Buddy

Bots IQ

Case Study

Cembre

Clamping

Covid

Date Codes

Design 2 Part

Direct Part Marking (DPM)

Dot Peen

Durable Mecco

EBS Ink Jet

Embossing Dies

Flexpak

Foundry Society

Foundry Solutions

Fundamentals

Gravotech

Handjet

Handstamp

Hexacon

HFO Demo Day

Honeywell

Hot Stamping

IMTS

ITT Gould Pumps

JetStamp

Labeling

Laser Marking

Laurie Barcaskey

Leading Marks

LEDLenser

Manufacturing Expo

Marking

Marking Indsutry Magazine

Max USA

Mfg Advanced Expo

MFG Day

Mitee Bite

Modern Casting

Modern Machine Shop

Nameplates

NTMA

OSHA Compliance

Pitt Chem Day

Presentations

Promotions

Reiner

Reiner Jetstamp 1025

Rising Rust Belt

Roll Dies

Scanners

SDS & MSDS

Signage

Stamping Press

Steel Stamps

Supply Chain

Tags

Tapmatic

Tapmatic MH Marking Head

TBH

TBH BF -Series

TBH GL-Series

Tech Article

Technifor

Technomark

Testimonials

Thermal Printing

Traceability

Trade Shows

Unique Device Identification (UDI)

Videos

WBENC - Women’s Business Enterprise National Council

WBE Women’s Business Enterprise

WBE - Women’s Business Enterprise

Workholding

WOSB - Women Owned Small Business

Zuess Marking

RSS Feed

RSS Feed