|

The TBH Compact and Modular LN 200 series stands out as a robust solution designed to efficiently extract laser fumes during soldering and laser processing.

The TBH Compact and Modular LN 200 series systems boast high-performance turbines that enable extraction over larger distances, offering decentralized arrangement possibilities. Rigorously tested by the Institute for Occupational Safety and Health (IFA) in accordance with DIN ISO standards, the LN 200 series guarantees effective filtration of gases and vapors, ensuring a safe working environment.

Understanding the differences between the models of the LN200 series will help you determine which is the best fit for your application. Below you will find the distinctive features of the LN 230, LN 260, and LN 265 as we highlight their applications and differences. LN 230: Compact Efficiency

LN 260: Versatility Redefined

LN 265: Maximum Extraction Power

Compliance and Safety Standards Across the LN 200 Series

The TBH Compact and Modular LN 200 series presents a comprehensive lineup of laser fume extraction systems, each tailored to specific needs. Whether prioritizing space efficiency, versatility, or maximum extraction power, users can find an ideal solution within the LN 230, LN 260, and LN 265 models, all while ensuring compliance with industry standards for a safe and healthy working environment.

0 Comments

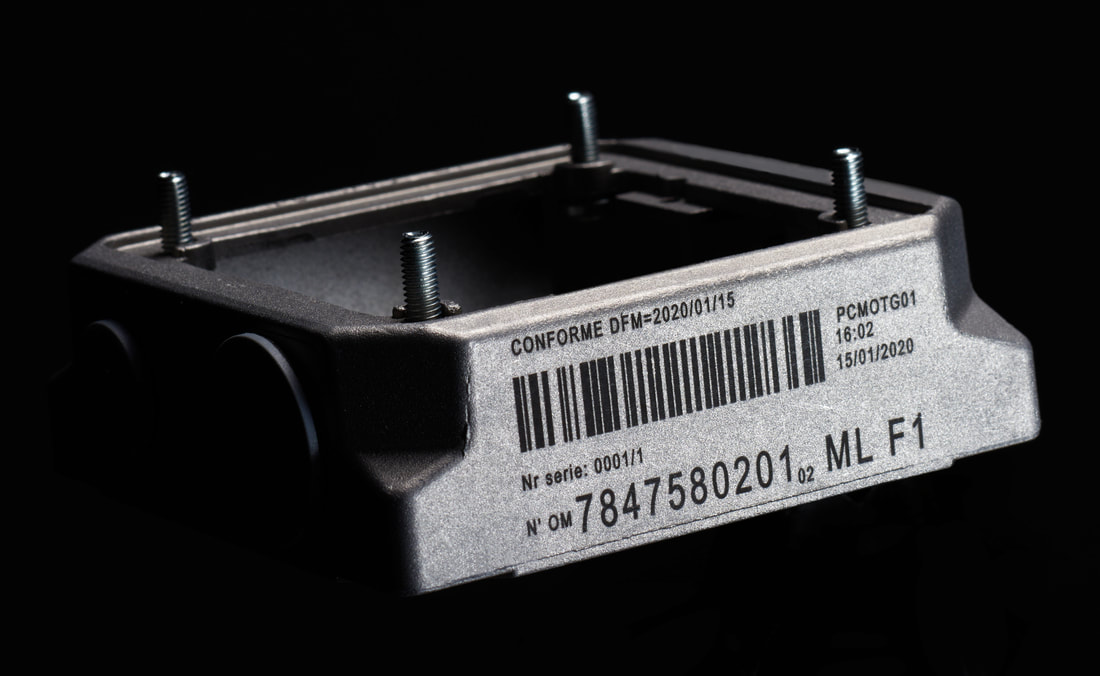

by Laurie Barcaskey This article was originaly written for the NTMA newsletter If you are considering adding or upgrading your marking process, laser technology might serve you well. However, the investment requires doing some homework to ensure the system you choose will optimize your capabilities and allow room to grow. Whether looking for a dedicated workstation or integrating the marking into a production line, identifying the primary features to fit your budget need consideration. Finding the best partner to provide the solution becomes important. What one machine shop finds suitable for them does not always prove the best for another shop. Laser marking offers more flexible technology over chemical etching, which it most commonly replaces. Programming through the software provides the ability to quickly change marking details without having to print a mask specific to each marking file. Upgrading from dot peen can prove beneficial, however for applications where stress fractures might be a concern, you may want to think again. Understanding Marking Areas Within the laser marking solutions you will find different power sources that are specific to the types of materials you need to mark. Fiber sources are most suited for metals and some plastics, while CO2 sources best serve organic materials like wood, leather, and glass, along with some other plastics. Applications where heat may impact the product, or high contrast is needed there are other specialized laser sources such as UV, Green, Mopa and Solid State. When referring to laser marking systems, the "marking area" is the maximum surface area on which the laser can engrave, etch, or mark at one time. This area is crucial for determining the size of the designs or texts that can be applied without repositioning the material. The size of this marking area is largely determined by the lens that is used in the laser system. Standard Marking Area The industry standard for a marking area is often cited as 4 inches by 4 inches (approximately 102mm x 102mm). This size is suitable for a wide range of applications, offering a good balance between size and precision for many products and components. However, specific requirements can vary, and so laser systems are equipped with lenses that can offer both smaller and larger marking areas. Role of the Lens The lens in a laser marking system functions similarly to a lens in a camera or a magnifying glass. It focuses the laser beam to a precise point on the material's surface. The characteristics of the lens, including its focal length, determine the size of the marking area and how finely the laser can focus.

Impact on Focal Distance The focal distance is the distance between the lens and the material being marked. It is critical for achieving clear, precise marks:

Advantages of Laser Technology Having the ability to achieve different mark results based on program settings makes laser technology attractive. Ranging from a light surface etch to deep engraving, and annealed marking for contrast you can meet the demands of identification for a multitude of applications with one system – a job shops dream come true. There are quite a number of advantage of using laser technology:

Software and Usability Many of today’s lasers include user-friendly intuitive software that includes common navigation allowing beginners to get started quickly. This may include preloaded settings based on the type of material, preferred type of mark, and batch size. Typical marking details such as alpha/numeric characters and symbols are available in standard True Type fonts. The ability for marking bar codes increases to include 1D and 2D codes in a variety of formats, where programmable dot peen systems only allow for 2D codes. For more experienced laser programmers, the ability to access the background tools for deeper dives into the software may be the key factor when evaluating the software capabilities. Logo Importing and Data Entry Importing logos is a frequent request. Most lasers will accept standard formats such as .jpeg, .bitmap and .eps, however some software platforms may require files be converted to a specific format. Job shops looking to expand through contract marking may face time spent converting file formats from what customers provide to what the laser will accept. Entering the data into the software becomes important when the data changes often. To optimize the accuracy bar code scanning information from work orders removes transposing characters or placing data in the incorrect fields. Most software platforms will also allow entering data from spreadsheets optimizing throughput of items with multiple fields such as nameplates. Yet other times, interfacing with a host computer for data entry streamlines the data entry real-time. Workstation Types and Safety

This leads to the types of workstations to consider, and safety is a key factor. For the sake of this article the focus is on a Galvo arrangement. A Galvo arrangement, short for "galvanometer arrangement," in the context of laser marking and engraving, refers to a system that utilizes galvanometer scanners to steer the laser beam across the target material's surface. These scanners contain mirrors that rapidly oscillate to reflect the laser beam in precise patterns, enabling the laser to etch, mark, or engrave with high speed and accuracy. This system contrasts with other types of laser positioning systems, such as gantry systems, which move the laser head or the workpiece mechanically over a fixed path. Sometimes Gantry style laser systems are more favorable for large batches of small parts. In Galvo arrangements Class I enclosed workstations meet OSHA standards for light-tight environments protecting the operators and area workers from stray beams. Laser providers typically offer a standard enclosure, and some can build a customized cabinet. Third-party automation organizations can also assist with custom enclosures and installations. Some key features of the enclosures to consider include the size and weight of parts being presented to the workstation, along with the access to the internal chamber. Manually operated, motorized and programmable doors are options with most laser suppliers. The ability to mark larger parts may require looking closely at the Z-axis, which is especially important to consider for proper focal distance. Options to automate the Z-axis are invaluable when part sizes change frequently and insure quick setup with accurate settings. While fixture requirements differ from impact marking, the tooling in laser applications assist with proper placement of the part for the marking process. Stability of the part during the marking process is more important than having it securely held. When available, T-slot bases offer the most flexibility for quick changeovers. Some shops choose to work without the enclosure in a Class IV arrangement. While these workstations offer greater flexibility with part sizes, they present the need for extra attention to safety in the area the laser is set up. The operator should be equipped with safety lens to suit the wavelength of the laser source. Preferably Class IV arrangements are placed in an area enclosed with laser safety barriers, if not in a room dedicated to laser marking. Maintenance and Partner Selection Another favorable feature of laser marking is the minimal maintenance requirements. By keeping the lens clean and the internal chamber of the enclosure free of debris and fumes from the marking process clear, legible mark results can be achieved consistently. A good air filtration system aids in this maintenance process. As you consider the partner for your project you want to explore the depth of their marking experience. Some partners are specific to laser marking, while others have a broader background in direct-part marking applications. The size of the organization will provide some indication of their ability to meet delivery and support post-sale issues. During the exploration period you will want to have test marking done on your materials and spend some time to be acquainted with their software. There are a lot of companies offering laser marking solutions, and like machine shops, they are not all the same. Choose wisely. Reiner jetStamp® 1025 is the ideal solution for printing on large areas, such as pallets, cardboard or packaging. compiled and edited by Bernard Martin The Reiner jetstamp 1025 has emerged as a technological marvel, seamlessly integrating the latest hardware and software features to redefine efficiency, and versatility in handheld product identification. Compact Powerhouse The Reiner Jetstamp 1025 sets a new standard for handheld inkjet printers with its compact and lightweight design. Entirely without cables or a fixed location, this hardware innovation not only ensures portability but also enhances user comfort, making it an ideal solution for on-the-go marking needs. The ergonomic design reflects a careful consideration of user experience, offering a comfortable grip for extended use without sacrificing performance.  The jetstamp 1025's ergonomic design reflects a careful consideration of user experience, offering a comfortable grip for extended use without sacrificing performance. The jetstamp 1025's ergonomic design reflects a careful consideration of user experience, offering a comfortable grip for extended use without sacrificing performance. Quick-Drying Ink Technology One of the standout hardware features is the incorporation of quick-drying ink technology. The Jetstamp 1025's ability to produce swift and efficient imprints on various surfaces sets it apart. This innovation not only accelerates the marking process but also guarantees clean and smudge-free results, contributing to enhanced productivity. But is also has an integrated capping system to seal the print head which keeps ink from drying out even with longer breaks between uses. User-Friendly Interface: Intuitive Controls for Seamless Operation Navigating the complexities of marking technology becomes intuitive with the user-friendly interface of the Reiner Jetstamp 1025. The latest software features empower operators to set-up and initiate marking tasks with ease. The interface is designed for efficient programming, ensuring a seamless experience for users at various skill levels. The integrated display shows the set print image easily legible at all times! Reiner has made several upgrades to software features that redefine versatility in marking capabilities. From product identification to date coding and batch numbering, this handheld inkjet printer adapts to diverse marking requirements. Wireless Connectivity The Reiner Jetstamp 1025 embraces the future with its wireless connectivity capabilities. This hardware feature allows users to control and program the device remotely, offering unparalleled flexibility in marking processes across different settings. Print images can be transferred to the mobile marking device by Bluetooth or USB. The integration of wireless technology positions the Jetstamp 1025 as a forward-thinking solution for those companies seeking enhanced operational efficiency. Reiner jetStamp® 1025 Specifications

TapMatic MH Series Marking Head allows you to mark the work piece during the CNC machining process! compiled & edited by Bernard Martin The TapMatic MH Series Marking Heads has emerged as a real game-changer by eliminating the need for costly secondary marking operations. These marking heads redefine the landscape by seamlessly integrating into the CNC machine just like any cutting tool in a rotary tooolholder, marking workpieces with unparalleled accuracy and speed. At the core of the TapMatic MH Series is a commitment to efficiency and precision. Unlike traditional methods that necessitate separate marking processes, these marking heads allow users to mark workpieces directly during the machining process. This not only streamlines operations but also significantly reduces costs associated with secondary marking. Whether on Machining Centers, CNC lathes, or manually controlled conventional machines, these heads effortlessly integrate into various setups Designed for ease of use, the TapMatic MH Series Marking Heads are remarkably simple to install. Whether on Machining Centers, CNC lathes, or manually controlled conventional machines, these heads effortlessly integrate into various setups. Their compact size ensures a seamless fit in tool magazines or turrets without causing interference, offering versatility across machining platforms. Operating the Marking Head is a breeze. No rotation is required – simply advance the head against the workpiece, charging the internal impact system, and rapidly feed away. Adjusting impact force and marking depth is equally straightforward, thanks to the intuitive design featuring a knurled sleeve. The TapMatic MH Series incorporates a cutting-edge shock absorption system, mitigating any recoil effects on the machine spindle or turret. This not only ensures the longevity of the equipment but also contributes to a smoother and more stable marking process. The versatility of the Marking Head extends to the types of marks it can make. Whether it's part numbers, date codes, batch codes, logos, or other information, these heads accommodate standard or custom-made stamps, allowing for a wide range of applications.  Tapmatic MH Series Marking Head Tapmatic MH Series Marking Head One of the standout features of the TapMatic MH Series is its commitment to precision. The marking location and depth are accurate and consistent, meeting the stringent requirements of modern manufacturing standards. The impact force and marking depth can be adjusted by simply turning the knurled sleeve. Efficiency is really enhanced by the quick change capabilities of the Marking Head. Characters and stamps are securely held and can be changed swiftly, ensuring minimal downtime and optimal workflow continuity. In todays just-in-time production world, time is of the essence. The TapMatic MH Series Marking Heads deliver remarkable speed, completing the stamping process in less than one second. This exceptional speed not only enhances efficiency but also contributes to meeting demanding production timelines. The CNC Marking Heads are for use with standard type or custom stamps! You can also order accessories like standard type or custom stamps separately. Please note the Marking Head accepts standard type directly or you can use one of the separateType Holders for quick replacement of characters and fast change over. The TapMatic MH Series Marking Heads redefine efficiency and precision in the world of manufacturing. From eliminating the need for secondary marking operations to offering user-friendly operation, shock absorption systems, and unmatched speed, these marking heads are poised to transform the way metalcutting machine shops approach product marking. As businesses seek innovative solutions to enhance their manufacturing processes, the TapMatic MH Series Marking Heads stand out as a beacon of efficiency and precision. The Northwestern Pennsylvania (NWPA) Chapter of the National Tooling and Machining Association (NTMA), in collaboration with Northwest Industrial Resource Center (NWIRC) and NEFF Automation as the premier sponsor, is thrilled to announce two exclusive events to learn about the latest developments in the manufacturing industry. Join Leading Marks LLC on April 30th a Red Fern in Kersey, PA, and May 2nd in Erie, PA, at the Ambassador Center, for the Manufacturing Advanced Expo 2024. These events offer a unique platform for manufacturers and job shops to explore the latest advancements in automation technology, robotics, manufacturing processes, and their role in enhancing the skilled workforce in Northwest Pennsylvania. A Glimpse into Tomorrow’s Manufacturing With a focus on educational sessions that spotlight advanced technology and applications, attendees will gain invaluable insights into how the industry is evolving. Experts will delve into topics that are at the forefront of manufacturing innovation, including 3D Robotic Guidance, Deep Learning Machine Vision, Robotic Palletizing, Welding, and Machine Tending, as well as Industry 4.0 Solutions. These discussions are designed not only to inform but also to inspire action and innovation within your operations. Leading Marks Industrial Identification Graphix Laser Engraver: compact, space-saving, and easy to use in any workshop. Graphix Laser Engraver: compact, space-saving, and easy to use in any workshop. IN our view one of the highlights of the expo will be the display presented by Leading Marks LLC, a pioneer in industrial identification for the shop floor. With a focus on making processes more efficient while prioritizing safety, Leading Marks is will showcase the capabilities of the Technomark Graphix Laser Engravers. The Technomark Graphix Laser Engraver stands out for its versatility and efficiency. Designed to cater to the demanding needs of metals and plastics, this technology can be seamlessly integrated into manufacturing processes or operated as a stand-alone workstation. During the expo, Laurie Barcaskey, President of Leading Marks, will conduct live demonstrations, offering a unique chance for attendees to bring their samples for test marking. This interactive experience will provide a tangible understanding of how Leading Marks' solutions can elevate the productivity and safety of your shop floor. Aside from the laser part marking technology, Leading Marks LLC also offers a range of other marking technologies, including thermal transfer labeling, ink marking, and other traditional marking methods. This comprehensive approach ensures that every manufacturing need is met with the highest standards of quality and efficiency. Be Part of the |

| MANUFACTURING ADVANCED EXPO – KERSEY PA

| MANUFACTURING ADVANCED EXPO – ERIE PA

|

Leading Marks is an authorized distributor of the GravoTech engraving systems and the MAX USA Bepop 4-color thermal printers. Specializing in identification requirements, Leading Marks believes in presenting options that allow the customer options to meet the expectations of the job and work within the available budget for the capital investment.

Engraving Machines

| Larger rotary engravers have varying field size for larger signs – and are great for light duty routing decorative designs specific to architectural projects. The GravoTech gantry lasers support the engraving a wide range of materials. The CO2 or fiber laser sources fulfill needs of cutting and engraving with power sources starting at 25W up to 150W. Systems with a combination of sources are also available. Leading Marks also supports engraving requirements post sale with sign holders, modular frames, engraving materials and other associated supplies. |

Thermal Printers

| The MAX USA thermal printers can be found in manufacturing facilities, chemical plants, educational & health care facilities and many more places of operations. MAX USA has been recognized worldwide as a leader of industrial tools and office products. The Bepop printers enable you to respond immediately when safety incidents occur – no more waiting for outsourced items or needs to purchase minimum quantities.

|

Signs to Go

It is also helpful to know the environment for which the label and sign will be used, and the driving need for it. With this information we can recommend the applicable material the sign should be made of meeting ANSI and OSHA requirements. Artwork in digital format expedites the ability to respond quickly.

Common standard and customized signs are available for biohazard and hazardous materials, safety, first aid, lockout tagout, machine operation and personal protection. Even rugged applications for aerial, pipelines, substations, traffic signals and other rugged industrial or construction site requirements.

Little did they know that in 2014 Laurie Barcaskey would pull out those very same prints for their custom solution and develop that into the product that is today’s Boss Buddy.

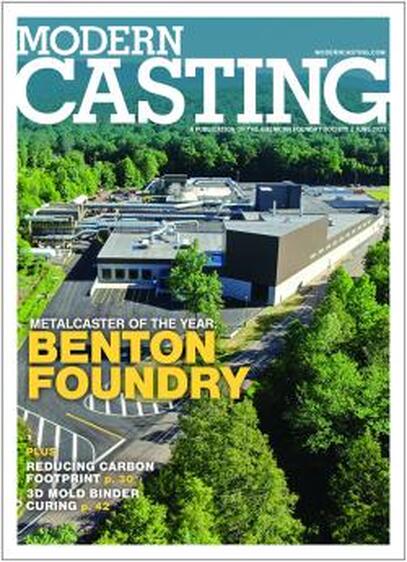

Benton Foundry has consistently reinvested profits into capital improvements, now operating a state-of-the-art facility with a capacity of 175 tons per day, aiming for 250. Unlike other foundries, Benton has prioritized core room expansion and strategic planning over short-term gains, contributing to its unbroken record of financial growth since 1975.

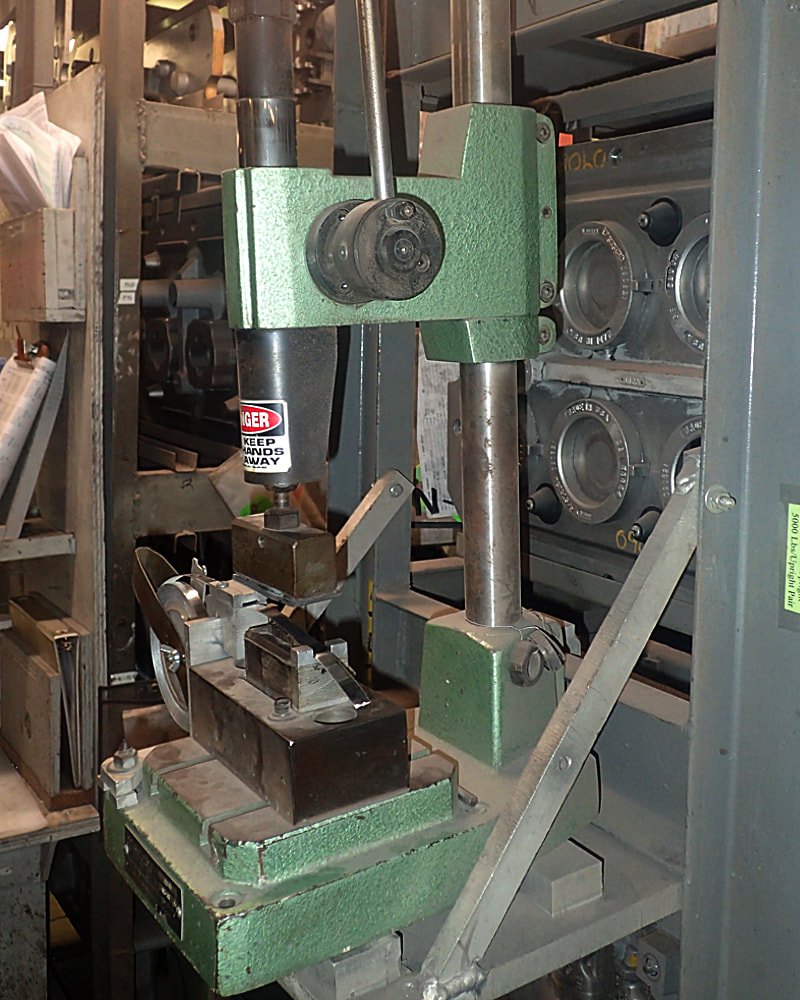

Back in 2002 Laurie Barcaskey at Leading Marks developed the precursor to the today's Boss Buddy as an application solution at Benton Foundary. Traditional embossing, as was being done at Benton, required a male and female die to create the embossed effect on thin gauge materials, often resulting in tearing of the material and inconsistent quality.

Fast forward to 2014 and Laurie ran into a similar application problem as the one that she had solved over a decade prior at Benton. And that began the official creation of the Boss Buddy. The inception of the Boss Buddy stemmed from a need to overcome the challenges that Benton had experienced, and dictated introducing a new method that utilizes a female urethane mating piece instead of both dies. This innovative approach not only reduced material waste but also ensured a more consistent quality of embossed characters on metal tapes, such as the foil or stainless tapes available for use with the today's Boss Buddy.

Unlike the typical wheel system that embosses one character at a time, today's Boss Buddy employs impact presses that emboss a complete set of characters at once. This method allows for the inclusion of custom characters and longer numbers, offering a solution that is both faster and more consistent. The Boss Buddy's adaptability extends to accommodating different types of metal tapes, catering to a wider range of industry needs.

Laurie's expertise in the marking industry played a crucial role in the development of the Boss Buddy, a manual system designed to emboss foil labels used commonly for pattern ID. This system addresses the industry's challenges head-on, providing a solution that leverages traditional components to replace outdated technology. The automation aspect of the Boss Buddy Plus signifies a notable advancement in the foundry sector, where efficiency and reliability are paramount.

The continuing story of the Boss Buddy is also one of collaboration and technical support. In the fall of 2023, Jason Karcher of Benton Foundry reached out to Laurie for assistance with the some of the components on the original design solution at their plant that was not functioning optimally. Actually, it's quite a testament to a design that had been in constant service for 20 years.

According to Jason Karcher, Tooling Department Manager at Benton Foundry, "There are few options for applying traceability for certified parts so it's essential that this unit remains operational for our process and pattern labeling. The unit was not operating correctly and some band-aids were used until Laurie visited and discussed the replacement parts and shared schematics."

Laurie proposed to replace some press parts and introduce new steel type characters, along with arranging for a spare energy section for hot swaps, exemplifies the ongoing commitment to streamlining maintenance allowing a quick return to operation and customer service at Leading Marks.

Karcher continues the story. "When the parts arrived, the unit was put back into first-class operation very quickly. It was a simple repair. I spent some time pulling the machine apart. Replaced the items that have worn over the 20-ish years in service. Surprisingly it wasn’t in all that bad shape. The replacement parts fit as expected! The Machine runs well. More importantly I have a greater peace of mind knowing I have replacement parts in house in the event something breaks."

"All-in-all the process of ordering, replacing, and stocking the replacement parts/springs & do-dads went very well. I really appreciate Laurie's advice and help on this machine. Her years of knowledge and experience are unmatched. I expect it to run problem free in the back ground for some time." said Karcher.

The Boss Buddy's exemplifies how addressing specific challenges through innovation can lead to advancements that benefit the entire sector. Benton Foundry's history, marked by consistent growth and strategic investments, provides the perfect backdrop for the development of such a transformative solution. The Boss Buddy is not just a product; it's a symbol of progress in the foundry industry, showcasing how traditional processes can be reimagined for greater efficiency and reliability.

As the foundry sector continues to evolve, the Boss Buddy stands as a prime example of how innovative solutions can drive industry-wide change. Its development process, from conception to implementation, underscores the importance of expertise, collaboration, and a deep understanding of industry challenges. The success of the Boss Buddy and its impact on Benton Foundry's operations highlight the potential for similar innovations to shape the future of manufacturing and industrial processes, ensuring sustainability and growth in an ever-changing technological landscape.

METALCASTER OF THE YEAR: BENTON FOUNDRY’S COREMAKING EXPANSION

The expansion reflects Benton's long-standing philosophy of reinvestment and modernization, a practice initiated by Fritz Hall in the 1970s and continued today under the leadership of his son, Jeff Hall, the current president.

| The foundry's approach has been to focus on smart, incremental growth through five-year capital expenditure plans, now in their ninth iteration. This strategy has seen Benton transform from a modest operation to a highly efficient, modern facility producing up to 225 tons a day, significantly above the industry norm. The expansion included a new core room, upgraded core sand system, enhanced maintenance and pattern storage areas, and improved environmental practices, among other advancements. Benton's commitment to environmental stewardship was also highlighted, with the creation of new wetlands to support local ecosystems. Moreover, the foundry has been successful in securing state funding to support many of its projects, showcasing its economic and environmental contributions to the region. |

Read the full article here

Department of Labor's National Emphasis Program Targets Warehouses and Distribution Centers

1/11/2024

From the OSHA News Release:

"In the past 10 years, warehousing and distribution centers have experienced tremendous growth with more than 1.9 million people employed in the industry. The Bureau of Labor Statistics data shows injury and illness rates for these establishments are higher than in private industry overall and, in some sectors, more than twice the rate of private industry.

"Our enforcement efforts are designed to do one thing: lead to permanent change in workplace safety," said Assistant Secretary for Occupational Safety and Health Doug Parker. "This emphasis program allows OSHA to direct resources to establishments where evidence shows employers must be more intentional in addressing the root causes of worker injuries and align their business practices with the goal to ensure worker health and safety."

Under this three-year emphasis program, OSHA will conduct comprehensive safety inspections focused on hazards related to powered industrial vehicle operations, material handling and storage, walking and working surfaces, means of egress and fire protection.

The Department of Labor's initiative comes as a proactive response to the evolving landscape of workplace safety. Warehouses and distribution centers, pivotal components of the supply chain, often contend with a multitude of hazards ranging from tripping and fall risks to more complex issues like equipment identification and emergency evacuation procedures.

What can you start to do right now to address this three year focus program is a comprehensive evaluation of your signage.

Key Area of Focus:

Signage and Identification

Signage plays a crucial role in communicating and mitigating potential hazards. Here are key items that companies should start reviewing related to signage:

Lock-Out / Tag-Out Procedures

- Ensure that clear and comprehensive signage is in place to communicate lock-out/tag-out procedures for machinery and equipment.

- Periodically review and update signage to reflect any changes in equipment or safety protocols.

Emergency Evacuation Routes

- Clearly mark emergency evacuation routes with visible signage throughout the facility.

- Conduct regular drills to ensure that employees are familiar with evacuation routes and assembly points.

Tripping & Fall Hazards

- Identify and label potential tripping and fall hazards, such as uneven flooring or exposed cords.

- Implement consistent and standardized signage to alert employees to these risks.

Pipe Labeling / Container Labeling

- Ensure that pipes and containers containing hazardous materials are clearly labeled.

- Review and update labeling regularly to reflect any changes in the types or locations of materials.

Shelving & Location ID

- Implement a systematic shelving and location identification system to enhance efficiency and reduce the risk of workplace accidents.

- Clearly label storage areas, shelves, and aisles for easy navigation and inventory management.

Equipment ID

- Clearly mark and identify all equipment, including forklifts, conveyors, and other machinery.

- Use standardized symbols and colors for quick and easy recognition.

Prioritizing Safety in Warehouses and Distribution Centers

Implementing clear and effective signage related to lock-out/tag-out procedures, emergency evacuation routes, tripping and fall hazards, pipe/container labeling, shelving and location ID, and equipment ID is a crucial step toward creating a safer work environment.

By investing in these initiatives, companies not only ensure compliance with regulatory standards but also foster a culture of safety that benefits both employees and the organization as a whole.

If you would like some assistance in developing developing signage to help you with compliance please feel free to reach out to us.

energy self-sufficient, network-connected dot peen machine.

Metalwerks dot peen sample

Metalwerks dot peen sample Metalwerks serve customers in the medical, industrial, and aerospace industries as well as research and development projects.

Typically alloy systems at Metalwerks include Fe, Ni, Co, Cu, Ti, and Zr in quantities ranging from 300 grams up to 6000 pounds. Through their network of outside processors they convert ingot into bar, plate, coil and/or sheet.

"The Easy, the Dot Peen marking system offers an unrivaled level of functionality. Being easy to use while delivering an exceptional operating experience to the user. Easy is ideal for mobile use, since the unique and durable, yet the lightweight chassis allows a user to mark medium to large parts in even the most difficult and inaccessible locations." said Laurie Barcskey, owner of Leading Marks, LLC.

"The dot peen marking system has served us quite well: No more smashed fingers, Clarity of the letters, and no problem training operators." says DeMailo.

I would recommend Leading Marks to other companies because they really understand and know their equipment. They are great to work with !!!!"

If you have any questions about portable dot peen marking solutions, get in contact with Laurie!

| The direct part marks commonly used for product tracking and traceability in industries such as automotive, electronics, pharmaceutical, defense and aerospace are tough for conventional scanners. Not so for the super-tough GranitTM 1920i industrial area- imaging scanner. Part of the durable, market-proven Granit family, the Granit 1920i scanner captures virtually any direct part mark with ease, along with standard 1D and 2D barcodes on printed labels. The secret lies in the Granit 1920i scanner’s highly innovative lighting system, which allows the imager to optimally illuminate marks of any type, on any surface. |

Powered by Honeywell’s revolutionary decoding architecture, the Granit 1920i scanner provides great scanning performance to read every type of direct part mark and ensure high first-pass read rates on even the toughest marks – regardless of size, surface, marking method or contrast.

The scanner is also capable of reading standard 1D and 2D barcodes on printed labels, delivering additional value – a single scanner to address your end-to-end scanning requirements across the complete workflow, from the production line to the warehouse.

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it.

Archives

May 2024

April 2024

March 2024

February 2024

January 2024

December 2023

November 2023

October 2023

September 2023

August 2023

July 2023

June 2023

May 2023

April 2023

March 2023

February 2023

January 2023

November 2022

October 2022

September 2022

August 2022

July 2022

May 2022

March 2022

December 2021

November 2021

September 2021

August 2021

July 2021

May 2021

March 2021

February 2021

January 2021

December 2020

July 2020

June 2020

May 2020

April 2020

March 2020

February 2020

January 2020

December 2019

November 2019

October 2019

September 2019

August 2019

July 2019

June 2019

April 2019

March 2019

January 2019

December 2018

November 2018

October 2018

September 2018

August 2018

July 2018

June 2018

May 2018

April 2018

March 2018

February 2018

January 2018

December 2017

October 2017

September 2017

July 2017

June 2017

May 2017

April 2017

December 2016

September 2016

August 2016

July 2016

June 2016

May 2016

April 2016

February 2016

January 2016

August 2015

October 2014

July 2010

Categories

All

AFS Medtalcasting Congress

AFS Pittsburgh

Area Tool

Arromark

Automator

Benson Foundry

Bepop

BizMix

Boss Buddy

Bots IQ

Case Study

Cembre

Clamping

Covid

Date Codes

Design 2 Part

Direct Part Marking (DPM)

Dot Peen

Durable Mecco

EBS Ink Jet

Embossing Dies

Flexpak

Foundry Society

Foundry Solutions

Fundamentals

Gravotech

Handjet

Handstamp

Hexacon

HFO Demo Day

Honeywell

Hot Stamping

IMTS

ITT Gould Pumps

JetStamp

Labeling

Laser Marking

Laurie Barcaskey

Leading Marks

LEDLenser

Manufacturing Expo

Marking

Marking Indsutry Magazine

Max USA

Mfg Advanced Expo

MFG Day

Mitee Bite

Modern Casting

Modern Machine Shop

Nameplates

NTMA

OSHA Compliance

Pitt Chem Day

Presentations

Promotions

Reiner

Reiner Jetstamp 1025

Rising Rust Belt

Roll Dies

Scanners

SDS & MSDS

Signage

Stamping Press

Steel Stamps

Supply Chain

Tags

Tapmatic

Tapmatic MH Marking Head

TBH

TBH BF -Series

TBH GL-Series

Tech Article

Technifor

Technomark

Testimonials

Thermal Printing

Traceability

Trade Shows

Unique Device Identification (UDI)

Videos

WBENC - Women’s Business Enterprise National Council

WBE Women’s Business Enterprise

WBE - Women’s Business Enterprise

Workholding

WOSB - Women Owned Small Business

Zuess Marking

RSS Feed

RSS Feed