|

This article about the Boss Buddy application at ITT Gould Pumps originally appeared in Modern Casting. We are republishing it now to coincide with the introduction of our new Boss Buddy Catalog. Be sure to grab a copy to download here on our Boss Buddy page! ITT Goulds Pumps Inc. (Seneca Falls, New York) needed to replace its aging pattern labeling equipment. This sand mold foundry manufactures industrial pumps used by customers in the oil, gas, mining, power generation, chemical, pulp/paper, and general industrial markets. Like many foundry operations, the resources and processes required for pattern labeling are being evaluated for the equipment needed and for their ease of use and manpower investment. The manufacturer depends on pattern labels to provide a mechanism for process control and quality tracking. Tracking piece quality throughout the process provides information that allows them to track operations and limit batch sizes if issues arise. In many foundries, the equipment used to apply the date codes, heat numbers and other traceable identification elements applied to patterns is aging badly. The preferred equipment, used for decades, requires operators to rotate a wheel engraved with a given character size, one character at a time. Rotating the heavy wheel to make multi-character labels is cumbersome and time-consuming. Additional character sizes meant the investment in duplicate systems to meet the various size requirements because the different-sized character sets and base equipment are not interchangeable. If multiple labels of the same legend are required, the process repeats. Manufacturers requiring high levels of traceability, such as automotive and aerospace, often have significant investments of time and equipment. These resources are needed to make all the additional labels used to identify line number, operator ID, or other fac- tors so they can minimize batch size if a recall occurs. The manufacturers that built these systems in the past have reduced available character sizes and don’t make spare parts for some systems. In addition, some marking companies have either shifted their focus to other, newer technologies where market size justifies production/development costs, or simply shut down. Many foundries are forced to hunt for second-hand parts online or use letters and numbers that can be pinned onto patterns. Parts bought online are hard to find and may be a short-lived solution when purchased used. Pinned on characters work but are not cost-effective. Their application and removal is tedious and time consuming, and the characters cannot always be reused. A shrinking workforce, needed for more important production tasks and not content with such menial work, merely compounds the problem. ITT Goulds Pumps had tagging equipment that embossed one letter at a time, which made producing tags a time-consuming process. Furthermore, if the letter wheel was not stopped at the correct spot, the tag would have to be scrapped.The tagging equipment operated like a labeler where the user must spin the letter wheel to the desired character, press the lever, and then repeat this process for each letter on each tag. Illegible tagging was also a problem. The manufacturer determined that new equipment was needed to con- tinue and improve the pattern labeling process. Numerous different solutions were tried. One solution was an automated dot peen marker with tag feeding accessories, but the marks were not legible after the tag was cast in due to the dot pattern. Work continued to improve the solution but after the process was fully implemented, the labeling results were still unsatisfactory. The search for a better, more legible solution proceeded. During this period, Kevin Lucas, pattern shop supervisor at ITT Goulds Pumps, set out to provide a temporary solution by 3D printing the legend plates. He developed a custom font of characters to create more distinguish- able marks. Though legibility was improved, the time to produce the 3D molded legends was not much faster than rotating wheels. Therefore, Lucas set out to find a more effective solution to support the organization. Lucas took the initiative to identify the foundry marking requirements before looking for new equipment. He determined that an effective solution must include:

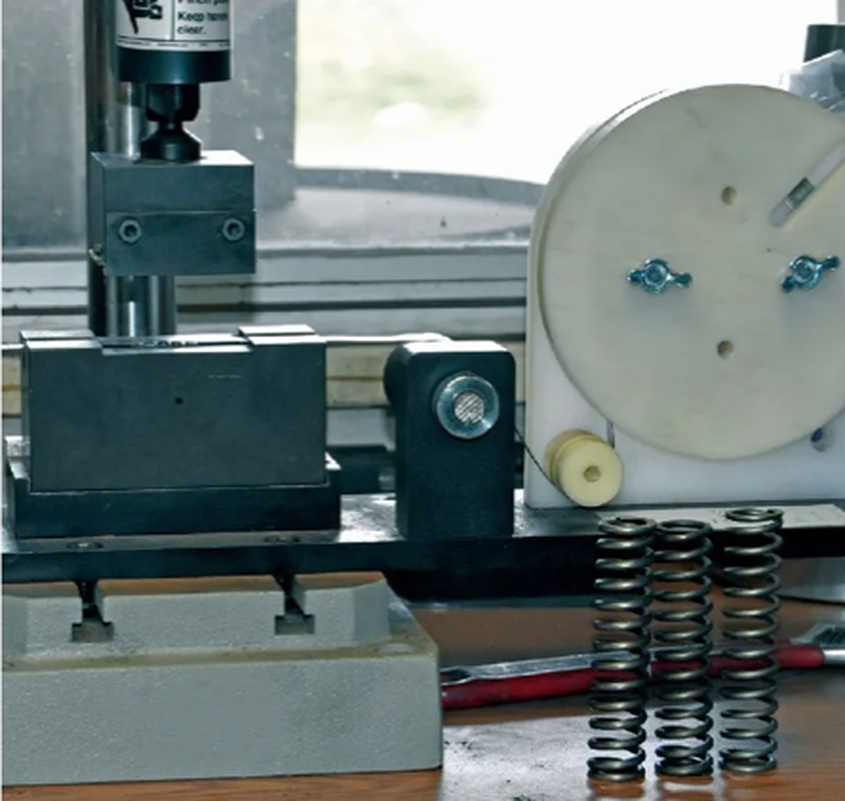

“We had been struggling with tagging legibility issues for years,” he said. “With our 3D printer, I had been adjusting and proving out a font and tag sizes. I printed thousands of tags, over the course of a year.”  He saw that the Boss Buddy embosses foil tape for use in foundry applications such as pattern labeling, and read that the Boss Buddy is compact, simple to operate, cost-effective and uses proven components customized for foundry requirements. Leading Marks had been working with many foundries around the U.S. to improve their processes. After working with Leading Marks to test date code samples in a couple of character sizes, Lucas said he obtained much more legible marks that were created in less than half the time of the older system and with far greater ease. With favorable results in hand, they began defining what the package should include: Interchangeable type characters in the custom font that Lucas had designed. Characters in a variety of sizes Manual Boss Buddy embossing system (vs. the automated system). The Boss Buddy system shipped to the facility in Seneca Falls, New York in the spring of 2019. After Lucas’ preliminary use of the Boss Buddy package in the pattern shop, it moved to the shop floor. Ryan Knapp, molding supervisor at ITT Goulds Pumps uses it daily, quick- ly creating the pattern labels needed by the foundry. During a follow-up meeting with Laurie Barcaskey from Leading Marks, Knapp created even more clearly defined embossed characters with a simple change in the spring used in the impact press. Knapp is relieved he no longer must use the old system, aka the “Spin to Win” for pattern labels. Knapp will be championing the efforts of other departments to employ this solution throughout the plant. When asked about the implemen- tation of the new system. Lucas said “I was pleasantly surprised that Leading Marks did not flinch when I men- tioned creating dies for the font I had been 3D printing.” “Leading Marks had some great ideas on implementing the tagging project. Prior to seeing the Modern Casting piece, I was going in a different direction. It saved a lot of time going with proven equipment and a knowledgeable vendor.” NEW 2023 Boss Buddy Catalog

0 Comments

|

Follow us on LInkedIN for the latest breaking news!

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it. Archives

May 2024

Categories

All

|

RSS Feed

RSS Feed