|

It's really a case study of how small family owned machine shops prioritize for growth.

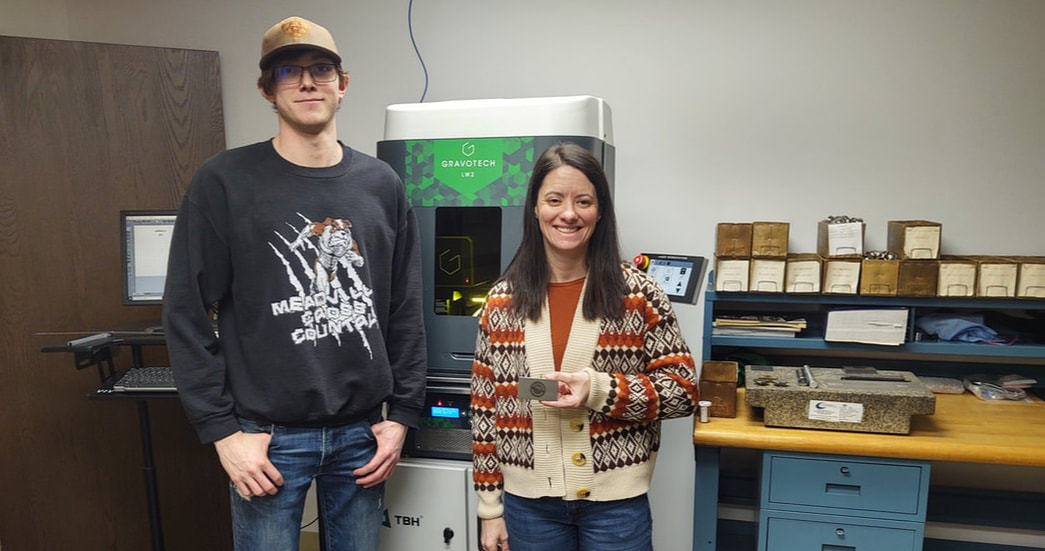

Area Tool & Manufacturing's Team: Trisha Proper - Office Manager, Dave Groshner - Surface Grind Department, Ethan Bates - CNC Mill Department, Dalton Conley - CNC Mill Department, Rob Hillman - CNC Mill Department, Jason Bowman - CNC Lathe Department, Matt Linz - Apprentice, Caroll Conley - WIRE EDM and Inspection, Jeff Ferguson - RAM EDM Department, Pat Winters - Maintenance Jesse Conley - Production, Ashleigh Wehrle - President

Area Tool & Manufacturing, Inc. was founded in Meadville, PA in 1976 by John Wehrle and business partner Wayne Shumaker. In 1990 John became the sole owner of the family business. Like many Tool & Die makers in Meadville, John got his start at Talon, Inc. Talon invented the zipper at the turn of the 20th Century and their renowned journeyman program has resulted in Meadville becoming known as the Tool and Die Capital of the World.

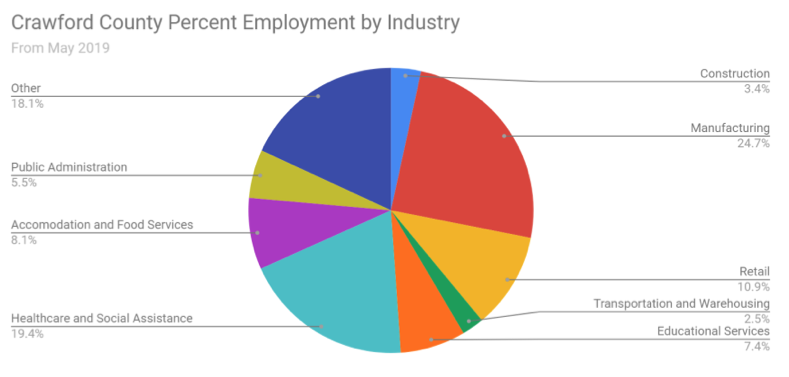

Meadville is located in Northwestern Pennsylvania and is the bedrock of the Crawford County economy, accounting for about a quarter of employment in the county. And those the jobs in the country are pretty much all in tool & die manufacturing!

According to the City of Meadville, “the Talon Corporation played a major role in the market development and manufacture of the zipper… In the 1980’s, the Great Lakes region saw a major decline in heavy industry. This blow to the local economy was softened by a subsequent surge in light industry, mainly tool and die machine shops, earning Meadville the nickname Tool City, USA.

Today, the Meadville area remains a leader in tooling, machining and advance manufacturing and the city serves as the region’s center for banking, education and social services.” A recent study undertaken at Allegheny College entitled , Trends in the Tooling and Machining Industry of Crawford County, Pennsylvania states, "Starting in the early 20th century, the Talon Company started the production of area toolmakers. Through their apprenticeship programs, workers learned the art of toolmaking. Many workers at Talon spun off to create their own companies. Since then, the tooling and machining industry has helped sustain the county as a major source of employment, revenue generator, and an important factor in the vibrancy of the real estate and retail sectors." Today Meadville is home to numerous small, medium and large tool and die shops, and is a leader in precision machining, plastic injection molding and aerospace engineering. "The industry is now transitioning to a third generation set of owners, who bring new attributes to the industry... For the first time in the history of the industry, women are either the CEOs or operations managers of an increasing number of tool shops." Area Tool & Manufacturing, Inc. certainly fits that description as a second generation woman owned family business, as it's now solely owned by Ashleigh Wehrle. Area Tool's TEAM consists of 13 employees with an average of 30 years of experience in the spare parts and mold industries and many of the shop floor employees are journeymen toolmakers. It's located just a few minutes from the Interstate 79 interchange in a 20,000 square foot climate-controlled building.

Area Tool exemplifies how the next generation of leadership is embracing technology and prioritizing how they grow their business. A recent blog post on their website titled, 4 Reasons to Source All Assembly Components from the Same Precision Machine Shop:

"Part buyers and engineers often assume they can save time and money on an assembly project by sourcing the components that make up their assembly from multiple shops. But the truth is that when more than one shop is responsible for precision machining as many as 100 components for a large assembly, issues with tolerance and fitment are common. The worst part? These problems remain hidden until the shipments arrive at your door. It’s only then that you discover that the components don’t fit together and the assembly doesn’t function properly."

That's also a trend in the Meadville market for small and mid sized shops according the the Allegheny College study, "Employment in our sample shops decreased by 18% between 2008 and 2018, a trend that reflects declines in manufacturing employment both in the United States and globally. This decrease in employment in Crawford County is not due to falling demand for toolmakers. Rather, many shops are still having difficulty finding skilled toolmakers. Technological change and automation in the industry have resulted in less need for skilled toolmakers. Most of the shops interviewed have invested heavily in new equipment, about $320,000 per shop within the past two years."

As a small shop, you have to pick and choose which area to invest your capital and then prioritize the order of that in investment. Sometimes it takes a few years. Wehrle continues, "We revisited the need for in-house laser marking in the fall of 2021. We often times found parts would be ready to ship late in the day except for the laser engraving requirement." That's a big problem for a machine shop that prides itself on meeting and exceeding delivery requirements. "One of our customers had a part scheduled to ship overnight, but they needed it sooner, so they asked, “Could you get someone on a flight tonight?” That same evening, an Area Tool team member flew to Boston and hand-delivered the part to the customer. Requests like this one aren’t feasible for OEMs. But because of our size, we can tailor our services to customers’ unique needs." said Wehrle

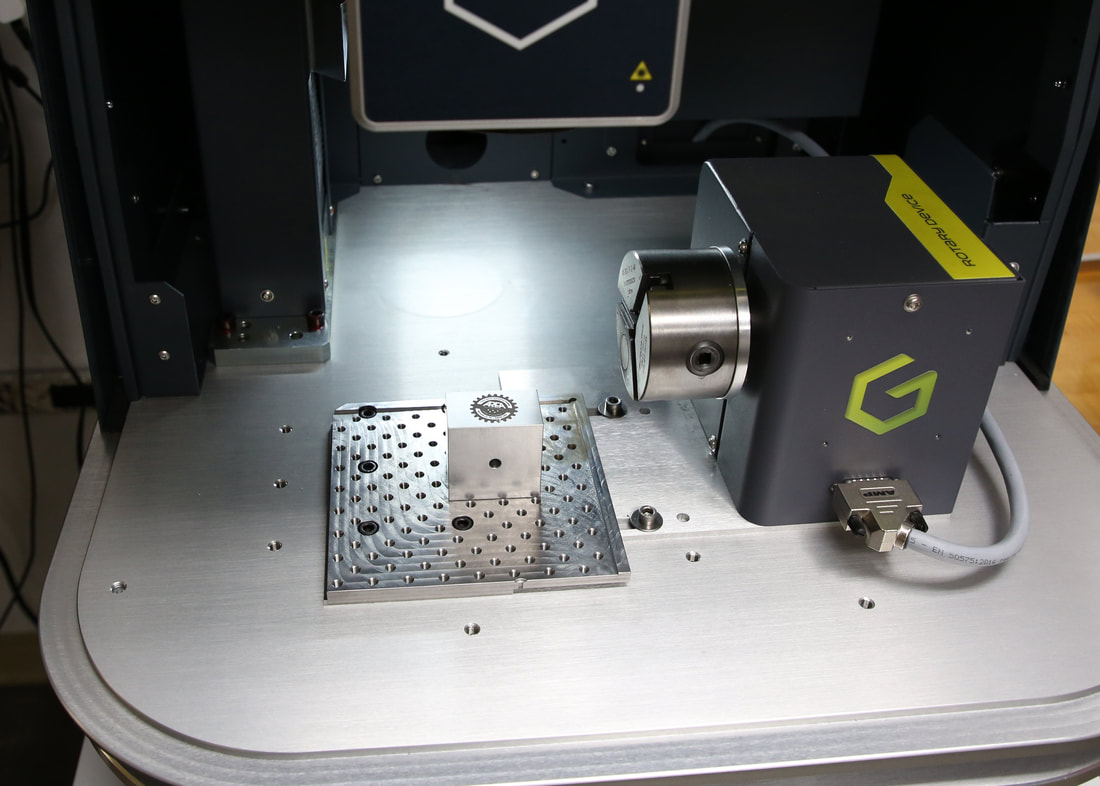

In January of 2022 Barcaskey installed a GravoTech LW2 which is a fully automated laser marking station.

"The GravoTech solution with rotary head was a perfect fit for the low volume mill and lathe parts we manufacture. We are also able to label in house fixturing and tooling for better organization. We have also replaced our dot peen for marking to provide a customers with more professional marking." said Wehrle. To sum it all up Wehrle says "Having the capabilities in house allows us to laser engrave and ship the parts 2-3 days sooner than if we continued to outsource." Automation continues to be embraced at every size machine shop as qualified labor continues to become more difficult to find.

0 Comments

|

Follow us on LInkedIN for the latest breaking news!

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it. Archives

May 2024

Categories

All

|

RSS Feed

RSS Feed