|

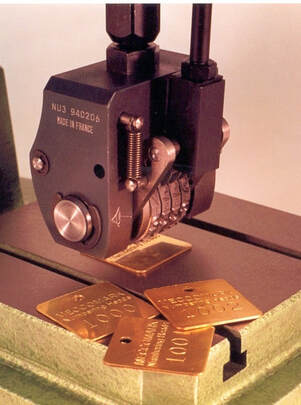

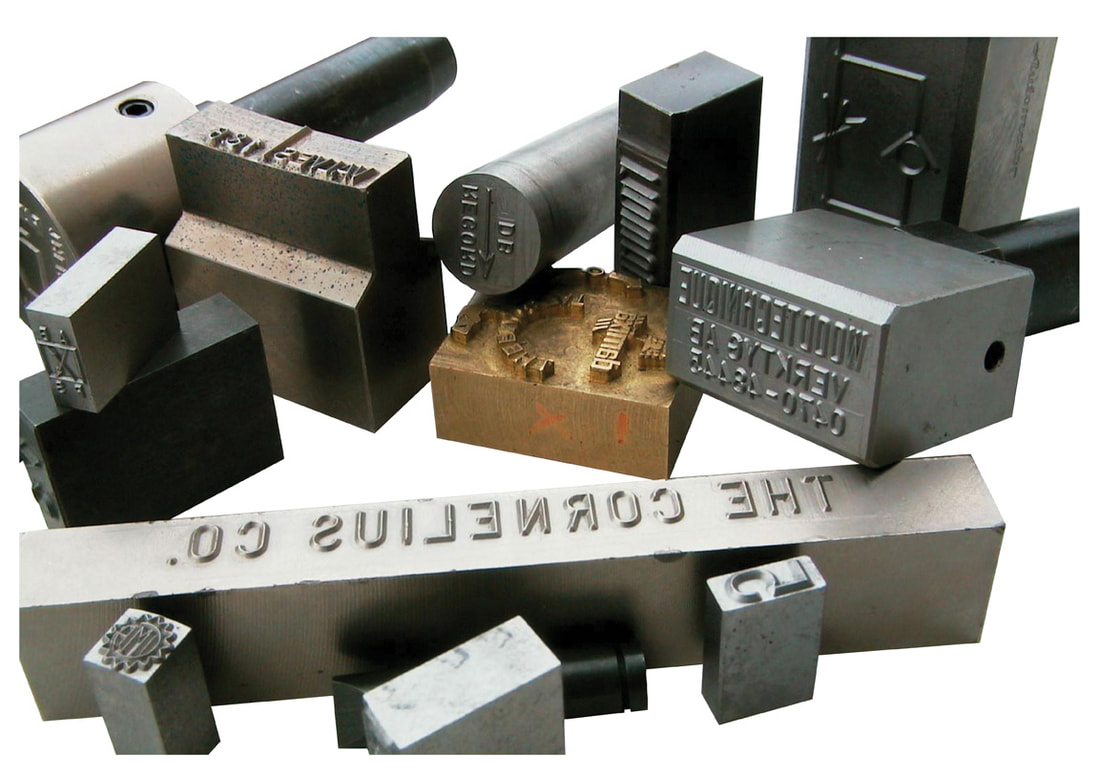

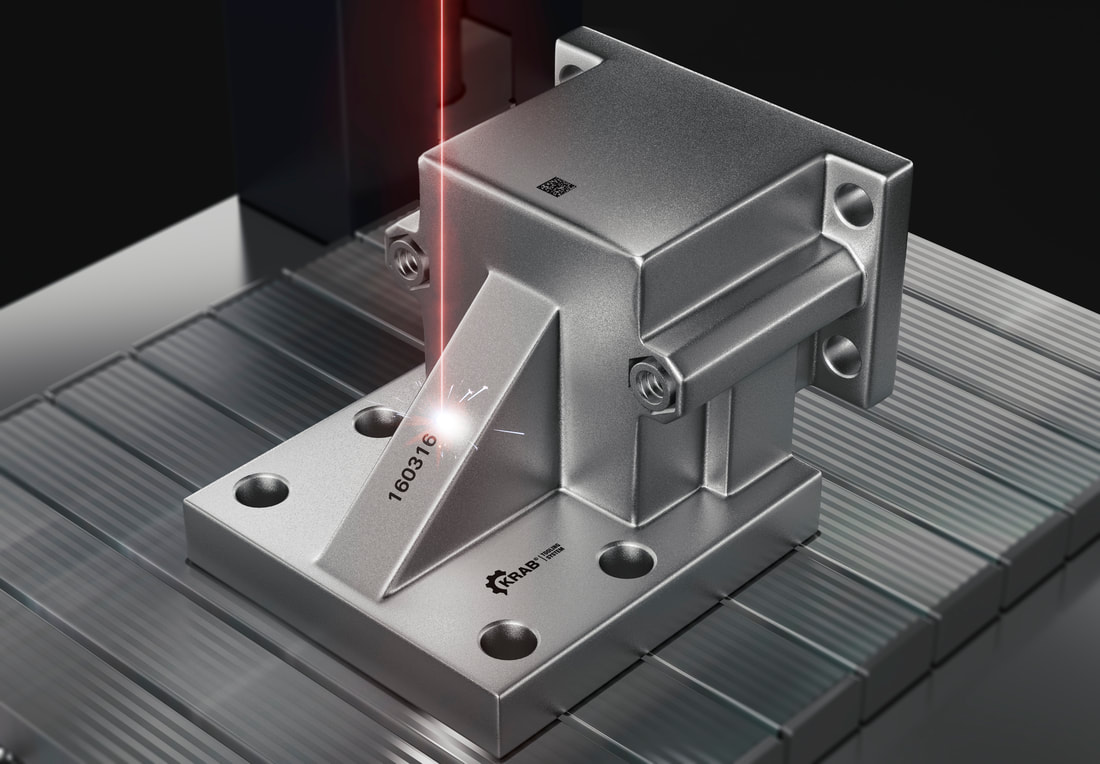

In essence, Direct Part Marking (DPM) is applying identification that lasts from cradle to grave and will sustain very rugged environments. Many US government agencies are making unique device identification (UDI) and direct part marking (DPM), mandatory. The private sector, from automotive manufacturers to medical offices have been using DPM more and more as they have embraced the Deming Principles of TQM. Direct Part Marking is used most frequently when marks are needed on a variety metals, plastics and wood. Common equipment solutions range from traditional hand stamping processes to cutting edge technology of fiber laser marking. Direct part marking is often a less costly alternative to purchasing RFID tags. When to Choose Direct Part Marking

Direct Part Marking Options

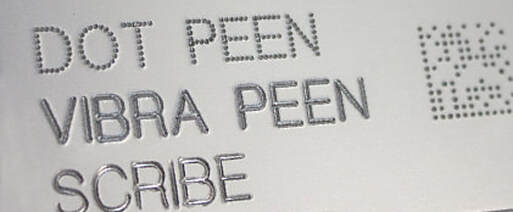

2D Codes: Most Popular for Direct Part Marking In most cases, direct part marking applications use two-dimensional (2D) barcodes such as Datamatrix or QR Code, which carry much more data than linear (1D) barcodes. By using 2D barcodes, manufacturers can also identify very small items and parts.  Dot Peen vs Vibra Peen vs Scribe and a 2D QR code Dot Peen vs Vibra Peen vs Scribe and a 2D QR code 2D codes can pack a large amount of data as opposed to linear codes because they can carry data in two directions on the code vs. just one. To give you an idea of the relative size, a 1D barcode can store around 25 characters up to about 80 characters depending on whether it’s Code 128 or Code 39, but a 2D code can store up to 2,000 characters. In the automotive sector, there is an established standard (AIAG B11) for direct part marking, and a number of large auto OEMs like Ford require suppliers of certain components to use DPM for part traceability. Manufacturers like to use the 2D code not only for the storage capacity, but for their relative size as well (square vs. rectangular). The flexibility of a 2D code allows for the variation in the amount of information stored in the barcode as well as the size of the item being marked. The most popular uses of the mark are for applications that require:

0 Comments

|

Follow us on LInkedIN for the latest breaking news!

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it. Archives

May 2024

Categories

All

|

RSS Feed

RSS Feed