|

TapMatic MH Series Marking Head allows you to mark the work piece during the CNC machining process! compiled & edited by Bernard Martin The TapMatic MH Series Marking Heads has emerged as a real game-changer by eliminating the need for costly secondary marking operations. These marking heads redefine the landscape by seamlessly integrating into the CNC machine just like any cutting tool in a rotary tooolholder, marking workpieces with unparalleled accuracy and speed. At the core of the TapMatic MH Series is a commitment to efficiency and precision. Unlike traditional methods that necessitate separate marking processes, these marking heads allow users to mark workpieces directly during the machining process. This not only streamlines operations but also significantly reduces costs associated with secondary marking. Whether on Machining Centers, CNC lathes, or manually controlled conventional machines, these heads effortlessly integrate into various setups Designed for ease of use, the TapMatic MH Series Marking Heads are remarkably simple to install. Whether on Machining Centers, CNC lathes, or manually controlled conventional machines, these heads effortlessly integrate into various setups. Their compact size ensures a seamless fit in tool magazines or turrets without causing interference, offering versatility across machining platforms. Operating the Marking Head is a breeze. No rotation is required – simply advance the head against the workpiece, charging the internal impact system, and rapidly feed away. Adjusting impact force and marking depth is equally straightforward, thanks to the intuitive design featuring a knurled sleeve. The TapMatic MH Series incorporates a cutting-edge shock absorption system, mitigating any recoil effects on the machine spindle or turret. This not only ensures the longevity of the equipment but also contributes to a smoother and more stable marking process. The versatility of the Marking Head extends to the types of marks it can make. Whether it's part numbers, date codes, batch codes, logos, or other information, these heads accommodate standard or custom-made stamps, allowing for a wide range of applications.  Tapmatic MH Series Marking Head Tapmatic MH Series Marking Head One of the standout features of the TapMatic MH Series is its commitment to precision. The marking location and depth are accurate and consistent, meeting the stringent requirements of modern manufacturing standards. The impact force and marking depth can be adjusted by simply turning the knurled sleeve. Efficiency is really enhanced by the quick change capabilities of the Marking Head. Characters and stamps are securely held and can be changed swiftly, ensuring minimal downtime and optimal workflow continuity. In todays just-in-time production world, time is of the essence. The TapMatic MH Series Marking Heads deliver remarkable speed, completing the stamping process in less than one second. This exceptional speed not only enhances efficiency but also contributes to meeting demanding production timelines. The CNC Marking Heads are for use with standard type or custom stamps! You can also order accessories like standard type or custom stamps separately. Please note the Marking Head accepts standard type directly or you can use one of the separateType Holders for quick replacement of characters and fast change over. The TapMatic MH Series Marking Heads redefine efficiency and precision in the world of manufacturing. From eliminating the need for secondary marking operations to offering user-friendly operation, shock absorption systems, and unmatched speed, these marking heads are poised to transform the way metalcutting machine shops approach product marking. As businesses seek innovative solutions to enhance their manufacturing processes, the TapMatic MH Series Marking Heads stand out as a beacon of efficiency and precision.

0 Comments

Several of the manufacturers that we represent will be displaying their products and introducing some technology at the International Manufacturing Technology Show September 12-17 in Chicago. If you are heading to the show be sure to stop and visit our friends at:

Join us for a one-day event on May 10, 2018 from 11:00 AM - 4:00 PM at the Ambassador Center in Erie, PA, showcasing the latest advancements in automation technology, robotics, manufacturing, and how they affect and compliment the skilled workforce in northwest Pennsylvania. Vendors will demonstrate the latest manufacturing technology for a smarter and more productive shop floor. Educational sessions will highlight advanced technology and applications. We will have on display an assortment of state-of-art marking technologies including laser marking, thermal transfer printing, and in-machine dot peen marking systems. As a featured sponsor of this Manufacturing Expo we will also showcase the use of mobile apps for record-keeping through the exhibitor-visitor interactions. Here is a preview of some of the products we will be featuring at the show!

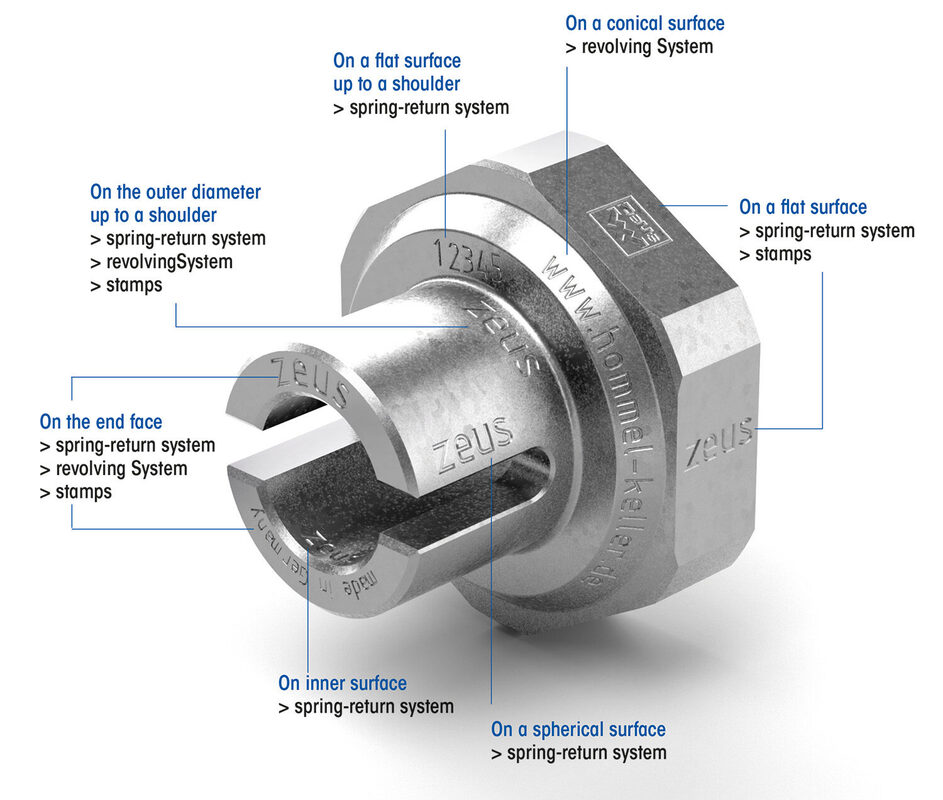

Laurie Barcaskey, President of Leading Marks LLC, will be at the 3rd Annual Associate Night for NTMA Akron and discussing solutions for marking machine components. There will also be several products on display as a focus of the discussions:

The event, held on March 20th from 5:30pm to 8pm will be held at the Hilton Fairlawn on 3180 W Market St, Akron, OH 44333. The mini-tradeshow style event is free for NTMA members and $15 for non-members. Drinks will be available and light appetizers will be provided. About the Speaker Laurie Barcaskey of Leading Marks is an authorized manufacturer’s representative with 30 years of experience and shop floor knowledge of solutions for industrial identification, part traceability and pipe testing. Laurie is the third generation of one of the marking industry’s most innovative and enduring family legacies, tracing back to 1889.Write something about yourself. No need to be fancy, just an overview. It’s a New Year with new regulations for manufacturing. Are you in compliance for the Respirable Crystalline Silica Standard for General Industry effective June 23, 2018? So, you ask, why would Leading Marks ask this question? It’s a good time to talk about the products offered through Leading Marks that aren’t marking. Many of the product solutions have a foundational tool that is multi-purposed. Take the impact press, that is the core component for the pattern labeling package offered to the casting industry. This same unit can be equipped with tooling for light duty bending, crimping, forming, riveting, staking, and other applications. Machining components that need marked takes tooling to make the part. The Tapmatic Tapwriter head is an example of using the core strength of the organization that provides tapping heads to machine shops and expanding to another process that can be done in-machine. Tapping attachment options include: self-reversing CNC tapping attachments, synchronized tapping, tension compression tap chucks, self-reversing manual tapping attachments with pre-selective torque drive, quick-change adapters, accessories, cutting fluids and dispensers. And the Hexacon soldering irons, did you know that a soldering iron is the base tool of a branding iron? Simply add an engraved marking die and you can add a variety of impressions to leather, wood, and other materials. But the strength of the Hexacon line is their heavy-duty soldering stations, and the variety of options between their pencil soldering irons. Link: OSHA Publication Fume extraction systems on the other hand, are a complementary product to the laser marking systems to help maintain the systems for optimal marks and make for a safe work station. Soldering also has the potential to create toxic environments where with the addition of fume extraction becomes a safer work cell with better air quality. Particulates in the air come from many processes, and often cannot be seen but over time results as a hazard for the worker. As companies are faced with new regulations, like the silica standard, their desire to maintain safe work places causes them to evaluate potential hazards for off-gassing and clean air. Many shops are equipped with full service dust collectors. However, the toxic fumes resulting from various processes like laser marking & welding, soldering, machining and others, benefit by installations of dedicated systems at the point of process. This provides more protection and higher quality air. Should you find you need assistance to improve your manufacturing processes for marking, soldering and machining, and improve the safety with the equipment – including air quality – let’s identify the solutions Leading Marks can assist with. Get in touch with us if you have any questions! |

Follow us on LInkedIN for the latest breaking news!

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it. Archives

May 2024

Categories

All

|

RSS Feed

RSS Feed