|

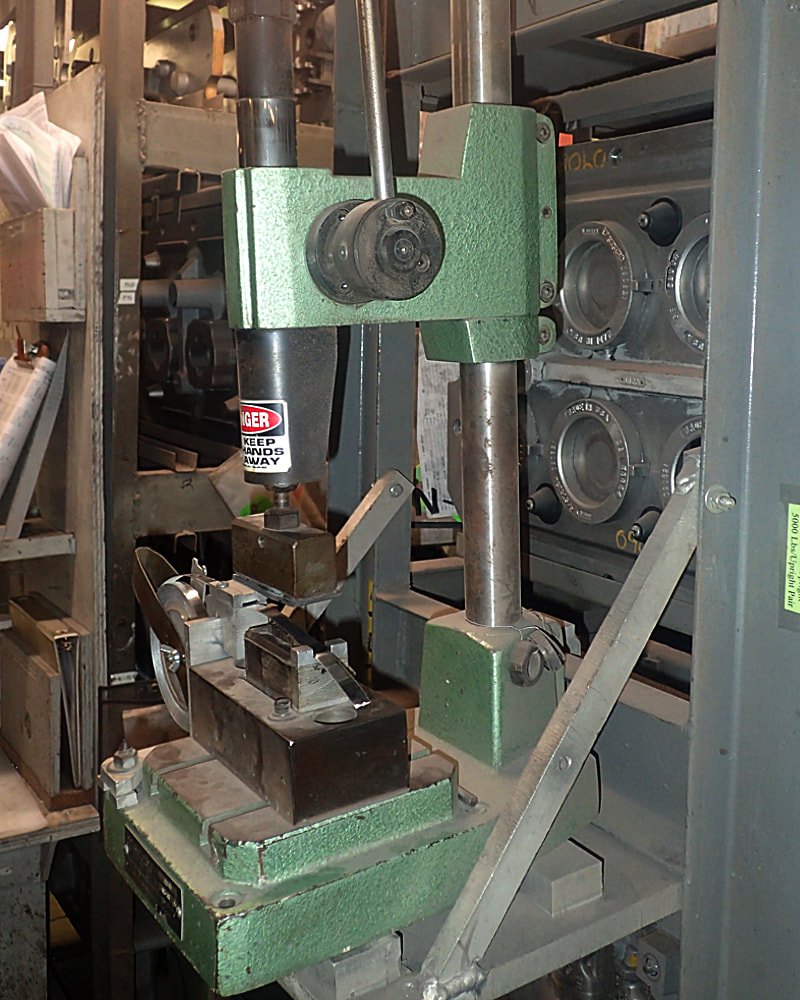

Back in 2002 Benton Foundry presented in the unique problem that needed to be solved. Little did they know that in 2014 Laurie Barcaskey would pull out those very same prints for their custom solution and develop that into the product that is today’s Boss Buddy. For almost a century, the Hall family has been at the forefront of the iron casting industry. Starting in the 1920s with Alfred J. "AJ" Hall, and continuing with his son, Alfred B. "Fritz" Hall, who became president of Benton Foundry in 1975, transforming it from a modest operation pouring 22 tons of iron daily into a visionary enterprise. By 1990, under Fritz's son Jeff, the foundry's capacity increased to 80 tons per day. Benton Foundry has consistently reinvested profits into capital improvements, now operating a state-of-the-art facility with a capacity of 175 tons per day, aiming for 250. Unlike other foundries, Benton has prioritized core room expansion and strategic planning over short-term gains, contributing to its unbroken record of financial growth since 1975. Back in 2002 Laurie Barcaskey at Leading Marks developed the precursor to the today's Boss Buddy as an application solution at Benton Foundary. Traditional embossing, as was being done at Benton, required a male and female die to create the embossed effect on thin gauge materials, often resulting in tearing of the material and inconsistent quality. Fast forward to 2014 and Laurie ran into a similar application problem as the one that she had solved over a decade prior at Benton. And that began the official creation of the Boss Buddy. The inception of the Boss Buddy stemmed from a need to overcome the challenges that Benton had experienced, and dictated introducing a new method that utilizes a female urethane mating piece instead of both dies. This innovative approach not only reduced material waste but also ensured a more consistent quality of embossed characters on metal tapes, such as the foil or stainless tapes available for use with the today's Boss Buddy. Unlike the typical wheel system that embosses one character at a time, today's Boss Buddy employs impact presses that emboss a complete set of characters at once. This method allows for the inclusion of custom characters and longer numbers, offering a solution that is both faster and more consistent. The Boss Buddy's adaptability extends to accommodating different types of metal tapes, catering to a wider range of industry needs. Laurie's expertise in the marking industry played a crucial role in the development of the Boss Buddy, a manual system designed to emboss foil labels used commonly for pattern ID. This system addresses the industry's challenges head-on, providing a solution that leverages traditional components to replace outdated technology. The automation aspect of the Boss Buddy Plus signifies a notable advancement in the foundry sector, where efficiency and reliability are paramount. The continuing story of the Boss Buddy is also one of collaboration and technical support. In the fall of 2023, Jason Karcher of Benton Foundry reached out to Laurie for assistance with the some of the components on the original design solution at their plant that was not functioning optimally. Actually, it's quite a testament to a design that had been in constant service for 20 years. According to Jason Karcher, Tooling Department Manager at Benton Foundry, "There are few options for applying traceability for certified parts so it's essential that this unit remains operational for our process and pattern labeling. The unit was not operating correctly and some band-aids were used until Laurie visited and discussed the replacement parts and shared schematics." Laurie proposed to replace some press parts and introduce new steel type characters, along with arranging for a spare energy section for hot swaps, exemplifies the ongoing commitment to streamlining maintenance allowing a quick return to operation and customer service at Leading Marks. Karcher continues the story. "When the parts arrived, the unit was put back into first-class operation very quickly. It was a simple repair. I spent some time pulling the machine apart. Replaced the items that have worn over the 20-ish years in service. Surprisingly it wasn’t in all that bad shape. The replacement parts fit as expected! The Machine runs well. More importantly I have a greater peace of mind knowing I have replacement parts in house in the event something breaks." "All-in-all the process of ordering, replacing, and stocking the replacement parts/springs & do-dads went very well. I really appreciate Laurie's advice and help on this machine. Her years of knowledge and experience are unmatched. I expect it to run problem free in the back ground for some time." said Karcher. The Boss Buddy's exemplifies how addressing specific challenges through innovation can lead to advancements that benefit the entire sector. Benton Foundry's history, marked by consistent growth and strategic investments, provides the perfect backdrop for the development of such a transformative solution. The Boss Buddy is not just a product; it's a symbol of progress in the foundry industry, showcasing how traditional processes can be reimagined for greater efficiency and reliability. As the foundry sector continues to evolve, the Boss Buddy stands as a prime example of how innovative solutions can drive industry-wide change. Its development process, from conception to implementation, underscores the importance of expertise, collaboration, and a deep understanding of industry challenges. The success of the Boss Buddy and its impact on Benton Foundry's operations highlight the potential for similar innovations to shape the future of manufacturing and industrial processes, ensuring sustainability and growth in an ever-changing technological landscape. METALCASTER OF THE YEAR: BENTON FOUNDRY’S COREMAKING EXPANSIONBenton Foundry, nestled within 200 acres of Pennsylvania's scenic landscape, has been recognized as the "Metalcaster of the Year" by Modern Casting magazine for its significant coremaking expansion. This recent project, completing 70,000 sq. ft. of new and renovated space in fall 2022, has notably enhanced the foundry's capacity, efficiency, and job creation. The expansion reflects Benton's long-standing philosophy of reinvestment and modernization, a practice initiated by Fritz Hall in the 1970s and continued today under the leadership of his son, Jeff Hall, the current president.

The full article provides a detailed account of Benton Foundry's strategic growth, technological advancements, and the positive impact of its recent expansion on the foundry industry and local community. For more insights into Benton Foundry's remarkable journey and its vision for the future, read the original article in Modern Casting magazine.

Read the full article here

0 Comments

Leave a Reply. |

Follow us on LInkedIN for the latest breaking news!

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it. Archives

May 2024

Categories

All

|

RSS Feed

RSS Feed