|

by Laurie Barcaskey Well, we’ve all heard it and hate the saying “but we’ve always done it that way.” Yes, I’m included in saying it, hearing it and resisting the thoughts of change at times but it’s inevitable and best if we embrace it and help make it happen.

Selling marking solutions is no different. I hear reasons like “I’m using Brand XYZ and they have always delivered”, or “it works for our needs right now.” Or even, "Well, it’s interesting but I’m not sure it fits our operation." And of course, "We’ve always done it this way."

Consider hand stamps for direct-part marking. Yes, it might be a caveman way of applying the mark and has its place in production. Let me ask a couple simple questions though.

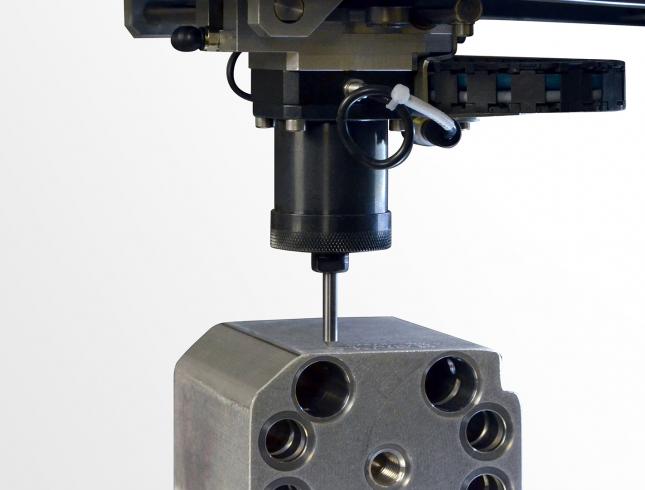

Well maybe a quick solution is to add a hand stamp holder to make it a safer marking process. Maybe it’s time to consider adding a holder/type arrangement or dot peen marking system that would provide you more consistency not to mention versatility. Then again, maybe it’s using paint markers or stencils & ink rollers to apply text to beams, cartons or preformed concrete components. What a mess and waste of material. Talk about penmanship – what’s it going to be like in the future now that they don’t teach cursive writing in schools? Some of the newest technologies for applying ink marks are handheld, Bluetooth or computer-driven and are more environmentally friendly – not to mention economical in the long run by eliminating material waste or one-time use of stencils.

Well it’s cumbersome to rotate wheels around one character at a time – especially when you might have to make 50 to 100 of the same legend. Using proven, traditional components I’ve been able to take a new solution to an industry that wasn’t even looking. Every mark you make that the customer sees is reflective of your corporate image. Branding is a topic for another day. Yes, you can get inexpensive solutions on the internet, especially for commodity items like labels and rubber stamps. But do you get the service and support that offers alternatives with your company’s interest in mind? Oh I forgot, you’ve always worked with that company and don’t want to make the change. There’s that word again – change. I might not be the one you have worked with for years on your marking solutions. You might not have even been aware that there are experienced consultants out there to help offer suggestions for you to consider. Well there is, and I’m happy to schedule an appointment to review your marking process to see how it might be improved. Identifying solutions and improving processes are what I do. What is it you have been resisting to change? ABOUT THE AUTHOR:

Laurie Barcaskey of Leading Marks is an authorized manufacturer’s representative with 30 years of experience and shop floor knowledge of solutions for industrial identification, part traceability and pipe testing. Laurie is the third generation of one of the marking industry’s most innovative and enduring family legacies, tracing back to 1889.

0 Comments

Leave a Reply. |

Follow us on LInkedIN for the latest breaking news!

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it. Archives

May 2024

Categories

All

|

RSS Feed

RSS Feed