|

TRC Services Inc. offers a full suite of Sucker Rod Products and Services is designed to help your rod pumping operation work more efficiently in the most cost-effective manner. "We found Leading Marks through a web search as we looked to improve our current dot peen equipment as we implemented the marking of the API monogram to our products." said Stephen Ewing, Quality Manager at Total Rod Concepts (aka TRC Services Inc).

"We would absolutely recommend Laurie Barcaskey of Leading Marks to other companies that have marking and traceability challenges because the customer service before and after the sale and the ongoing technical support is fantastic. The products are top of the line and performance has changed our processing for the better."

0 Comments

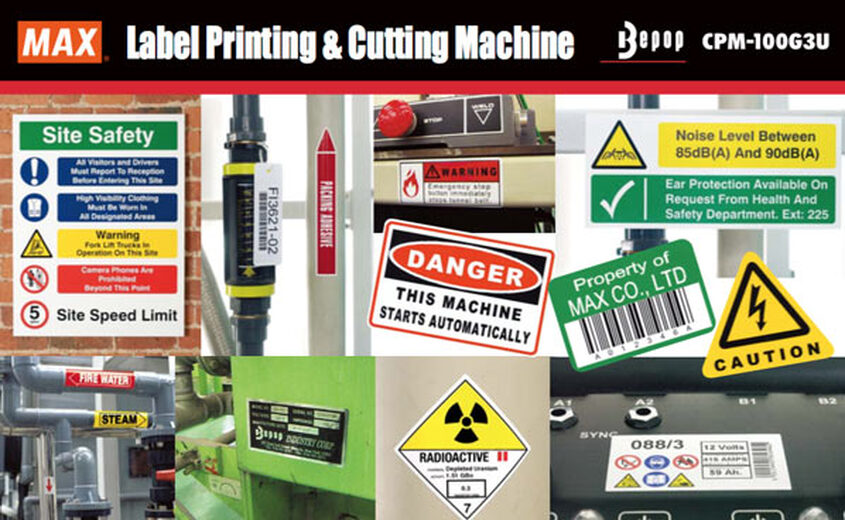

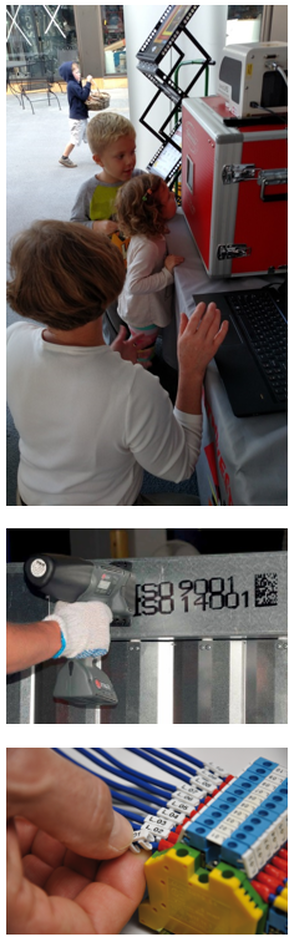

by Laurie Barcaskey Labeling allows identification to be applied and maintains component integrity with no deformation to the surface. Optional adhesives allow the labels to be used in various environments and offer tamper-evident options for security. While there are cost savings in some instances to have labels pre-printed and ready for on-demand application, at other times there is a distinct benefit to printing labels on-demand where label design is done in-house for quick edit corrections or job-specific requirements. Printing In-House In house printing provides flexibility for label details and printing/applying in individual work cells. Volume printing can be maximized through stocking materials for just-in-time printing. If you want to see some of these tools in action, check out the video below. Pre-Printed Labels Pre-printed labels allow you to brand the product with corporate logos and color schemes while heightening the specific product details or cautions associated with their use. About the Author Laurie Barcaskey of Leading Marks is an authorized manufacturer’s representative with 30 years of experience and shop floor knowledge of solutions for industrial identification, part traceability and pipe testing. Laurie is the third generation of one of the marking industry’s most innovative and enduring family legacies, tracing back to 1889. Come and see what these high school students can accomplish or better yet, volunteer to help out. You can also meet with Laurie Barcaskey, President of Leading Marks. Laurie is volunteering at this event that runs from April 13 @ 8:00 am – April 14 @ 5:00 pm. There will surely be tons of sparks and lots of excitement! Complete our registration form to let us know you will be joining us! Southwestern Pennsylvania BotsIQ is a manufacturing workforce development program of the Pittsburgh Chapter National Tooling & Machining Foundation, a non-profit 501(c)3 organization. The program is affiliated with the National Robotics League and is managed by New Century Careers. What is BotsIQ? BotsIQ is a manufacturing workforce development program whose goal is to provide a pathway for high school students to learn about rewarding career options in manufacturing. This is accomplished by inviting students to participate in an exciting, hands-on high school robotics competition. Laurie Barcaskey, President of Leading Marks LLC, will be at the 3rd Annual Associate Night for NTMA Akron and discussing solutions for marking machine components. There will also be several products on display as a focus of the discussions:

The event, held on March 20th from 5:30pm to 8pm will be held at the Hilton Fairlawn on 3180 W Market St, Akron, OH 44333. The mini-tradeshow style event is free for NTMA members and $15 for non-members. Drinks will be available and light appetizers will be provided. About the Speaker Laurie Barcaskey of Leading Marks is an authorized manufacturer’s representative with 30 years of experience and shop floor knowledge of solutions for industrial identification, part traceability and pipe testing. Laurie is the third generation of one of the marking industry’s most innovative and enduring family legacies, tracing back to 1889.Write something about yourself. No need to be fancy, just an overview. Laurie Barcaskey, President of Leading Marks LLC, spoke at the American Foundry Society’s February meeting in Scottdale, Pa.

Thomas Erie, Inc. is a Girard, PA based company that produces quality metal stamped parts. They serve markets such as electronics, automotive and aerospace Their capabilities include stampings from 0.25 to 0.55 mm, Gasketing, embossing & anodizing. Thomas Erie, Inc. is part of the Thomas Group, the world’s largest independent supplier of tinplate and aluminum components for the aerosol, pharmaceutical and cosmetic industry. The Thomas Group employ 500 people worldwide. They produce stamped and deep drawn parts on progressive tools and transfer presses in Germany, the USA, Spain, China and Argentina. "We have been working with Laurie Barcaskey since 2014." said Foster Nickel the Toolroom Manger.

Foster explained, " We originally purchased an Automator Laser Engraver for marking our parts only for identification purposes. One day shortly after purchasing the engraver we found ourselves with a rush order for some debossed parts and the vendor we typically purchase our graphite anodes from could not meet our customer’s timeline. " "We don't have a high speed mill able to make the fine detail on the anodes required to meet our customer specifications and typically outsource this item. We were able to utilize the laser engraver to cut the graphite anode and then using our EDM sinker make our own debossing tool with laser point accuracy." said Foster, "This cut our lead time down from weeks to minutes and eliminated the cost of outsourcing completely." Foster found Leading Marks' Laurie Barcaskey very helpful. "Laurie offers good pricing, provides good service and is able to answer our questions. We would recommend her for your next project!" Get in touch with Laurie with any questions! JADCO Manufacturing, Inc. in Harmony , PA, is a leading global provider of wear resistant steel products to combat impact and abrasion challenges for over 40 years. Founded in August of 1980, JADCO offers an unparalleled array of proprietary products to optimize operations.

by Laurie Barcaskey When I started Leading Marks in June of 2014 it was exciting, frightening and everything entrepreneurs prepare for (and some things they don’t!) Over the last three years I have researched and chosen vendors and products that are current with innovative solutions and supportive staff. This includes global names in the marking and traceability arena. Some I’ve known for years and others only more recently.

My interaction with you on these projects allowed me to gain insight to other manufacturing challenges. And I value the lessons I have learned, the information you have shared, and most of all for becoming not only my customer, but my friend. The one lesson I have learned is that “Traceability” is not an isolated need for any one particular industry. Traceability pertains to assets, and assets are defined by the organization, and the process. The asset has attributes that help define and track through the various process to help organizations capitalize on the information captured for delivery updates, insure stock availability, confirm proof of delivery, proof of work, and a multitude of other aspects that minimize an organizations risk. Should you be considering a project with me now, I hope to gain your trust and partner with you to implement the solution. Should you be considering a new marking or traceability project – give me a shot! ABOUT THE AUTHOR:

Laurie Barcaskey of Leading Marks is an authorized manufacturer’s representative with 30 years of experience and shop floor knowledge of solutions for industrial identification, part traceability and pipe testing. Laurie is the third generation of one of the marking industry’s most innovative and enduring family legacies, tracing back to 1889. Neff Automation in Warrendale, PA specializes in providing automation products and solutions to enhance manufacturing and assembly processes and improve productivity in a wide variety of industries. We focus our activities toward manufacturing process improvement, productivity enhancement, total cost management and downtime reduction. Neff offers Automation Products, Sub-Assembly, Custom Designed Solutions and Inventory Optimization. "Neff Automation, previously Intek Systems, once shared office space with Laurie Barcaskey. Since she started Leading Marks, Neff have partnered with her for our marking requirements. She also makes referrals to us when automation is required." said, Rob Kozminski, Panel Shop Foreman at Neff.

"Leading Marks was able to help change our process for making panel plates. Previously we were going outside to engrave 2-ply materials, which caused lost production time for travel. With the new thermal printing process we are now able to print in-house and make adjustments to layouts as needed, and this printing process has also expanded our printing capabilities. It also allows us to use the printed label as a template for drilling holes for switches at the same time." continued Rob. "We would definitely recommend Leading Marks. Laurie is easy and pleasant to work with, and responds to emails and questions quickly. We appreciate her broad knowledge on marking technologies and that if she doesn’t know the answers she will put us in contact with someone who does." Join Leading Marks Founder, Laurie Barcaskey and the Pittsburgh Business Times to mix, mingle and network with Pittsburgh business professionals at BizMix at an evening networking reception. This event will be held in the second floor private event space at Roland's Seafood Grill in the Strip District.

Would you like to discuss your current marking projects with Leading Marks? Laurie will he talking about industrial strength solutions for

Your reservation includes:

|

Follow us on LInkedIN for the latest breaking news!

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it. Archives

May 2024

Categories

All

|

RSS Feed

RSS Feed