Leading Marks Featured Products Laser Marking is permanent identification without product deformation up to deep engraving can all be accomplished with laser marking. Depending on the substrate being marked, the available cycle time, and the power of the laser permanent direct-part marks can be applied quickly from stand-alone work stations to fully integrated marking systems.

RFID or Radio-Frequency IDentification is becoming a popular labeling method that allows for quickly locating a component or asset, capture equipment details, and much more. Options for RFID labeling can be simple labels with adhesive, or rugged devices that survive in almost any environment.

0 Comments

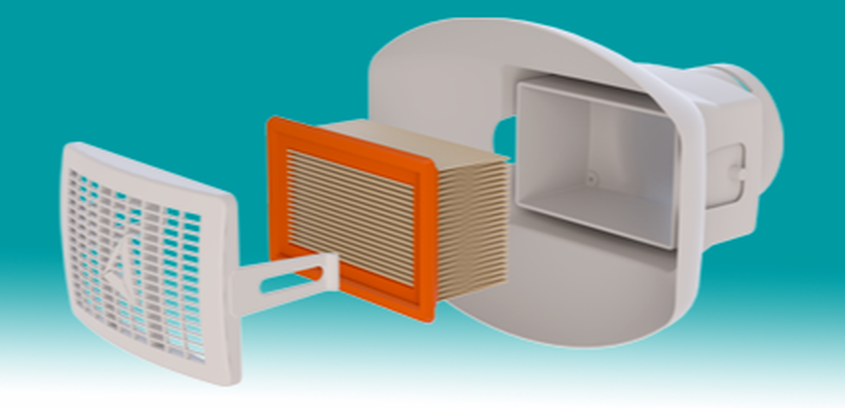

Come and see what these high school students can accomplish or better yet, volunteer to help out. You can also meet with Laurie Barcaskey, President of Leading Marks. Laurie is volunteering at this event that runs from April 13 @ 8:00 am – April 14 @ 5:00 pm. There will surely be tons of sparks and lots of excitement! Complete our registration form to let us know you will be joining us! Southwestern Pennsylvania BotsIQ is a manufacturing workforce development program of the Pittsburgh Chapter National Tooling & Machining Foundation, a non-profit 501(c)3 organization. The program is affiliated with the National Robotics League and is managed by New Century Careers. What is BotsIQ? BotsIQ is a manufacturing workforce development program whose goal is to provide a pathway for high school students to learn about rewarding career options in manufacturing. This is accomplished by inviting students to participate in an exciting, hands-on high school robotics competition. It’s a New Year with new regulations for manufacturing. Are you in compliance for the Respirable Crystalline Silica Standard for General Industry effective June 23, 2018? So, you ask, why would Leading Marks ask this question? It’s a good time to talk about the products offered through Leading Marks that aren’t marking. Many of the product solutions have a foundational tool that is multi-purposed. Take the impact press, that is the core component for the pattern labeling package offered to the casting industry. This same unit can be equipped with tooling for light duty bending, crimping, forming, riveting, staking, and other applications. Machining components that need marked takes tooling to make the part. The Tapmatic Tapwriter head is an example of using the core strength of the organization that provides tapping heads to machine shops and expanding to another process that can be done in-machine. Tapping attachment options include: self-reversing CNC tapping attachments, synchronized tapping, tension compression tap chucks, self-reversing manual tapping attachments with pre-selective torque drive, quick-change adapters, accessories, cutting fluids and dispensers. And the Hexacon soldering irons, did you know that a soldering iron is the base tool of a branding iron? Simply add an engraved marking die and you can add a variety of impressions to leather, wood, and other materials. But the strength of the Hexacon line is their heavy-duty soldering stations, and the variety of options between their pencil soldering irons. Link: OSHA Publication Fume extraction systems on the other hand, are a complementary product to the laser marking systems to help maintain the systems for optimal marks and make for a safe work station. Soldering also has the potential to create toxic environments where with the addition of fume extraction becomes a safer work cell with better air quality. Particulates in the air come from many processes, and often cannot be seen but over time results as a hazard for the worker. As companies are faced with new regulations, like the silica standard, their desire to maintain safe work places causes them to evaluate potential hazards for off-gassing and clean air. Many shops are equipped with full service dust collectors. However, the toxic fumes resulting from various processes like laser marking & welding, soldering, machining and others, benefit by installations of dedicated systems at the point of process. This provides more protection and higher quality air. Should you find you need assistance to improve your manufacturing processes for marking, soldering and machining, and improve the safety with the equipment – including air quality – let’s identify the solutions Leading Marks can assist with. Get in touch with us if you have any questions! Leading Marks, LLC is excited to announce that we are now distributors for TBH North America (TBH). TBH is a leading, global manufacturer of high-quality fume extraction and filtration equipment. TBH offers the broadest range of product in the industry to cover your needs regardless of industry. Their 25 years of experience, coupled with their modular design, gives TBH the knowledge and flexibility to address their customers’ specific needs. Their innovative lab can help you solve your problems in a timely and cost-efficient manner. Various manufacturing processes can cause hazardous, toxic vapors, gases, aerosols and particulates that can be harmful to your health. Even nontoxic substances affect workplace quality by dust and odor nuisance. Adding a fume extractor or filtration system to your manufacturing line can eliminate many of these hazards. Here are some of the applications where TBH can help provide equipment to remove toxic, hazardous and damaging by-products:

The Basic Filtration, or BF series for short, contains all essential functions of a filter and extraction system as a compact base model. The systems of the BF series can be equipped with various engine concepts and filters. The proven modular design of TBH with its many advantages is used. The differential pressure display monitors the saturation filter. All systems of the BF series have a particularly energy-saving blower, high negative pressure and powerful control electronics. The Basic Filtration, or BF series for short, contains all essential functions of a filter and extraction system as a compact base model. The systems of the BF series can be equipped with various engine concepts and filters. The proven modular design of TBH with its many advantages is used. The differential pressure display monitors the saturation filter. All systems of the BF series have a particularly energy-saving blower, high negative pressure and powerful control electronics. The TBH line of fume extraction and filtration systems has many unique features that make their products more user-friendly, flexible and cost-effective:

Thomas Erie, Inc. is a Girard, PA based company that produces quality metal stamped parts. They serve markets such as electronics, automotive and aerospace Their capabilities include stampings from 0.25 to 0.55 mm, Gasketing, embossing & anodizing. Thomas Erie, Inc. is part of the Thomas Group, the world’s largest independent supplier of tinplate and aluminum components for the aerosol, pharmaceutical and cosmetic industry. The Thomas Group employ 500 people worldwide. They produce stamped and deep drawn parts on progressive tools and transfer presses in Germany, the USA, Spain, China and Argentina. "We have been working with Laurie Barcaskey since 2014." said Foster Nickel the Toolroom Manger.

Foster explained, " We originally purchased an Automator Laser Engraver for marking our parts only for identification purposes. One day shortly after purchasing the engraver we found ourselves with a rush order for some debossed parts and the vendor we typically purchase our graphite anodes from could not meet our customer’s timeline. " "We don't have a high speed mill able to make the fine detail on the anodes required to meet our customer specifications and typically outsource this item. We were able to utilize the laser engraver to cut the graphite anode and then using our EDM sinker make our own debossing tool with laser point accuracy." said Foster, "This cut our lead time down from weeks to minutes and eliminated the cost of outsourcing completely." Foster found Leading Marks' Laurie Barcaskey very helpful. "Laurie offers good pricing, provides good service and is able to answer our questions. We would recommend her for your next project!" Get in touch with Laurie with any questions! Neff Automation in Warrendale, PA specializes in providing automation products and solutions to enhance manufacturing and assembly processes and improve productivity in a wide variety of industries. We focus our activities toward manufacturing process improvement, productivity enhancement, total cost management and downtime reduction. Neff offers Automation Products, Sub-Assembly, Custom Designed Solutions and Inventory Optimization. "Neff Automation, previously Intek Systems, once shared office space with Laurie Barcaskey. Since she started Leading Marks, Neff have partnered with her for our marking requirements. She also makes referrals to us when automation is required." said, Rob Kozminski, Panel Shop Foreman at Neff.

"Leading Marks was able to help change our process for making panel plates. Previously we were going outside to engrave 2-ply materials, which caused lost production time for travel. With the new thermal printing process we are now able to print in-house and make adjustments to layouts as needed, and this printing process has also expanded our printing capabilities. It also allows us to use the printed label as a template for drilling holes for switches at the same time." continued Rob. "We would definitely recommend Leading Marks. Laurie is easy and pleasant to work with, and responds to emails and questions quickly. We appreciate her broad knowledge on marking technologies and that if she doesn’t know the answers she will put us in contact with someone who does." |

Follow us on LInkedIN for the latest breaking news!

AuthorS

There are variety of authors who write the articles including marking manufacturers. You'll find a lot of technical imformation, application stories and new product releases here. Be sure and click a category below that interests you to search it. Archives

May 2024

Categories

All

|

RSS Feed

RSS Feed